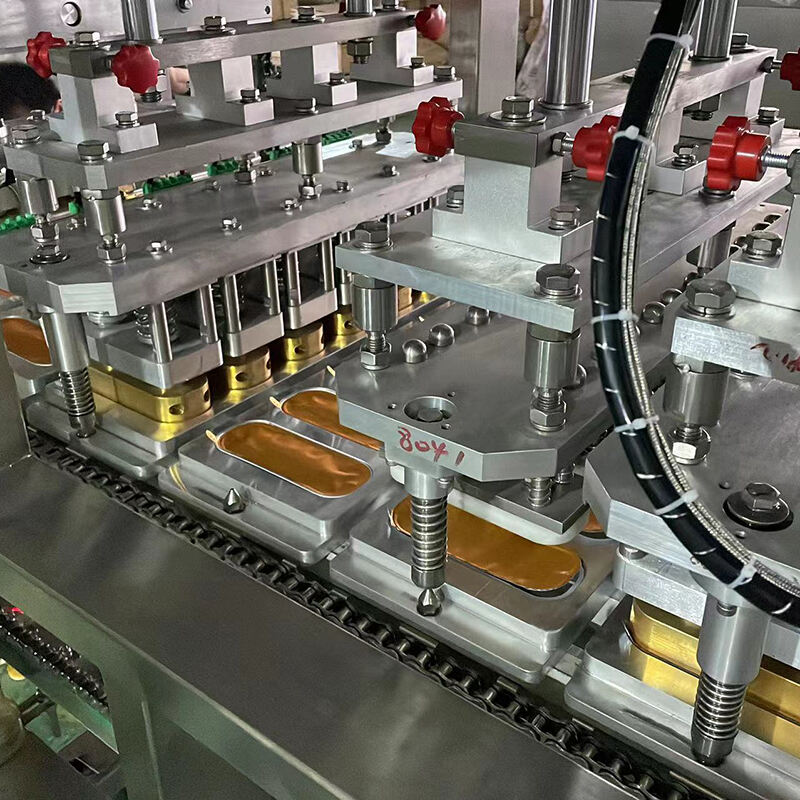

plastic tray sealing machine

The plastic tray sealing machine is an innovative packaging solution designed to efficiently seal plastic trays with a variety of products, ensuring freshness and extending shelf life. This machine is equipped with advanced technology that automates the sealing process, making it ideal for food production and packaging industries. The main functions include heat sealing, cutting, and shaping of plastic trays, which are essential for creating a secure and tamper-evident seal. Technological features such as programmable control systems, precision sensors, and variable speed capabilities ensure consistent and high-quality output. Applications of the plastic tray sealing machine are diverse, ranging from packaging of fruits, vegetables, and meats to pharmaceuticals and electronics, making it a versatile solution for various industries.