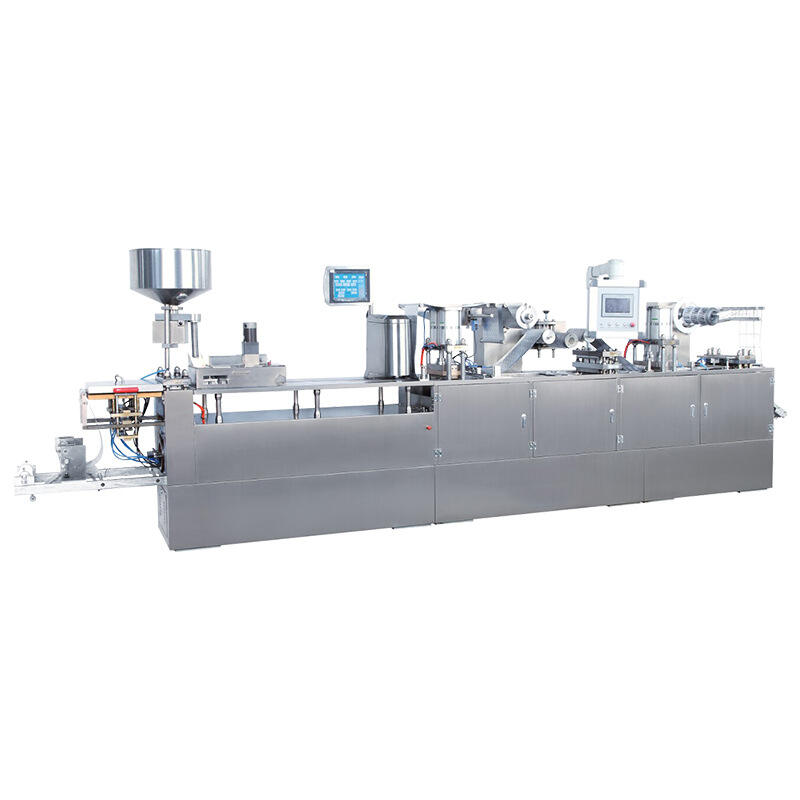

thermoforming packaging

Thermoforming packaging is a versatile and innovative packaging solution that involves heating a plastic sheet to a pliable temperature, forming it over a mold, and then trimming it to create a final product. Its main functions include protection, preservation, and presentation of a wide range of products. Technological features of thermoforming packaging include custom mold capabilities, which allow for intricate shapes and designs, and the ability to use various plastic materials to meet different requirements. The packaging is lightweight, durable, and often transparent, which makes it ideal for displaying products effectively. It finds applications across industries such as food, pharmaceuticals, electronics, and more, offering a sustainable and cost-effective alternative to traditional packaging methods.