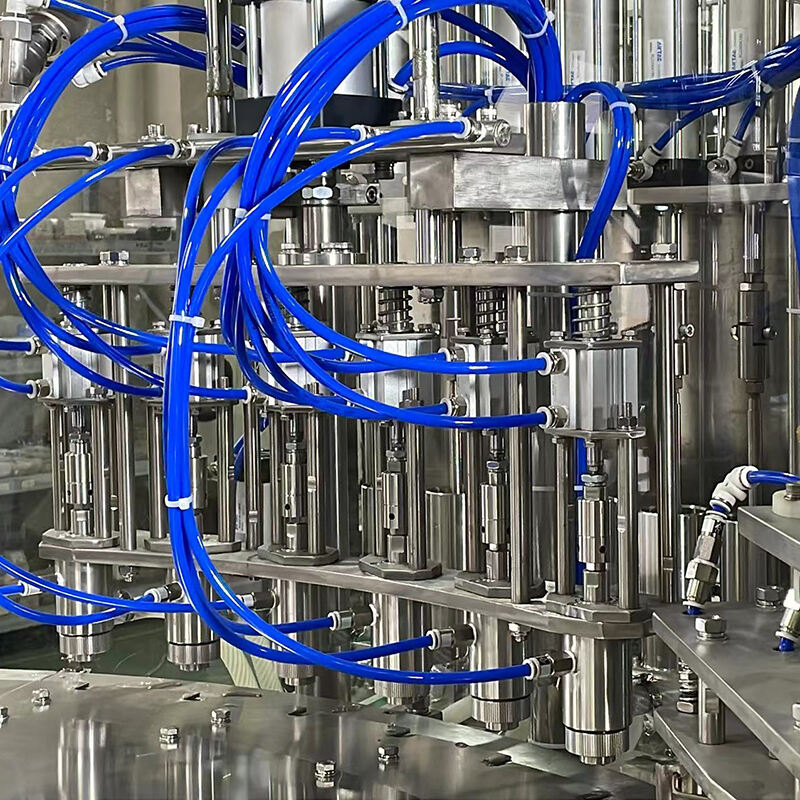

spout filling machine

A spout filling machine is an automated industrial equipment designed to fill containers with liquids accurately and efficiently. Its primary function is to dispense a precise volume of liquid, such as beverages, chemicals, or pharmaceuticals, into bottles, cans, or other packaging formats. Technological features of a spout filling machine include a filling valve system, level sensors, and a control panel for setting fill levels and speeds. These machines can be semi-automatic or fully automatic, with some models featuring advanced features like leak prevention and spill reduction systems. Applications span across various industries, including food and beverage, cosmetics, pharmaceuticals, and chemicals, where precise and hygienic filling is crucial. The machine's design ensures minimal product waste and consistent fill levels, which is vital for maintaining product quality and meeting packaging standards.