spouted pouch filling machine

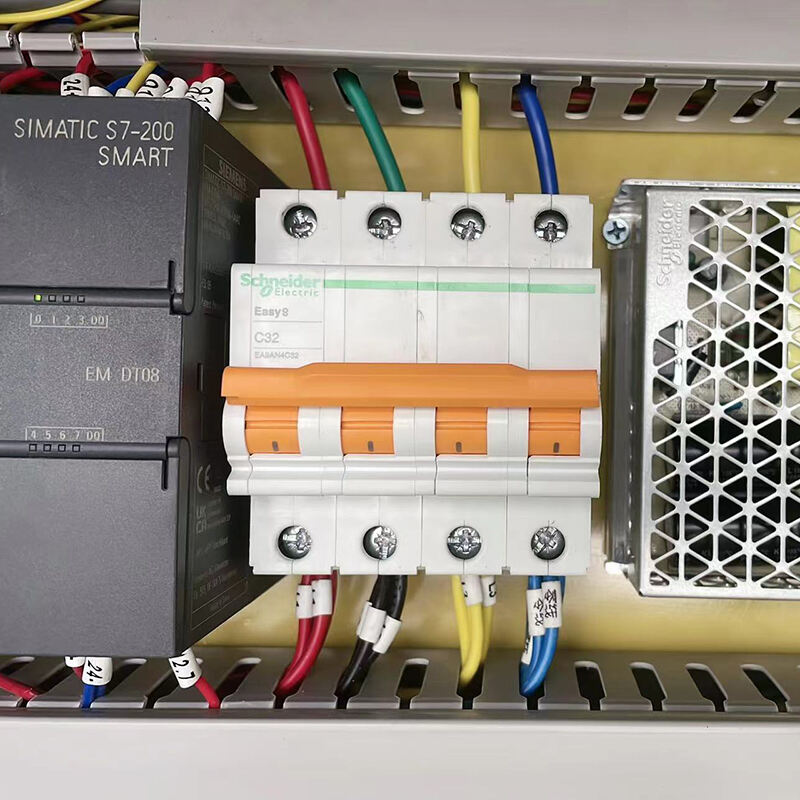

The spouted pouch filling machine is a state-of-the-art system designed for efficient and precise packaging of liquids and semi-solids into spouted pouches. Its main functions include automatic pouch loading, precise filling, sealing, and date coding, all within a compact footprint. Technological features such as a user-friendly touch screen interface, advanced PLC control systems, and high-precision filling nozzles ensure accuracy and consistency. This machine is ideal for a wide range of applications including food and beverage, pharmaceuticals, and cosmetics, offering flexibility for various product viscosities and container sizes.