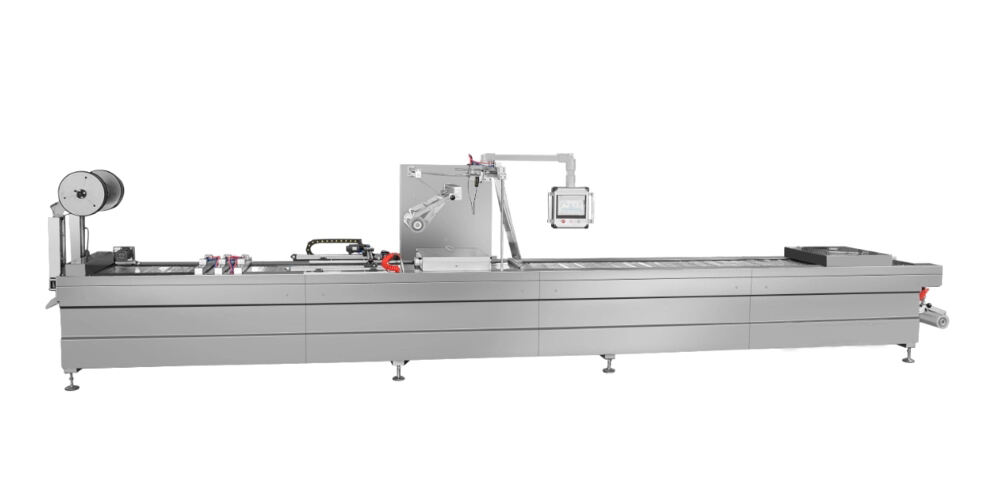

vacuum thermoforming

Vacuum thermoforming is a versatile process used to shape plastics into a variety of forms, primarily for packaging, automotive parts, and product enclosures. The main function of vacuum thermoforming involves heating a plastic sheet until it becomes pliable, then stretching it over a mold and applying a vacuum to suck the plastic tightly against the mold. Once cooled, the plastic retains the mold's shape. Technological features of this process include precise temperature control, quick mold changes, and automated systems that increase efficiency. Applications span across industries from medical devices to aerospace components, showcasing its flexibility and utility.