As manufacturing volumes increase and product variations expand, traditional manual packaging methods often become a production bottleneck. Labor dependency, inconsistent output, and limited scalability make it difficult for manufacturers to maintain efficiency and quality at higher throughput levels.

An automatic packing line addresses these challenges by integrating multiple packaging processes into a coordinated, automated system. Rather than focusing on a single machine, automatic packing lines are designed to optimize the entire packaging workflow—from product infeed to final output—making them an increasingly common choice in modern production facilities.

An automatic packing line is a fully or semi-automated system that performs a sequence of packaging operations with minimal human intervention. These operations may include product feeding, counting or weighing, primary packaging, sealing, secondary packaging, inspection, labeling, and final discharge.

Unlike standalone packaging machines, an automatic packing line functions as a system, where each component is synchronized to ensure continuous, stable production.

Most automatic packing lines are built around functional modules rather than isolated equipment:

Product feeding and infeed systems

Measuring, filling, or counting units

Packaging and sealing machines

Conveying and transfer systems

Inspection, rejection, and labeling units

Centralized control system (PLC and HMI)

The exact configuration depends on the product type, packaging format, and production requirements.

The process begins with a controlled feeding system that delivers products to the line at a consistent rate. This may involve conveyors, vibratory feeders, or robotic pick-and-place units, depending on product characteristics.

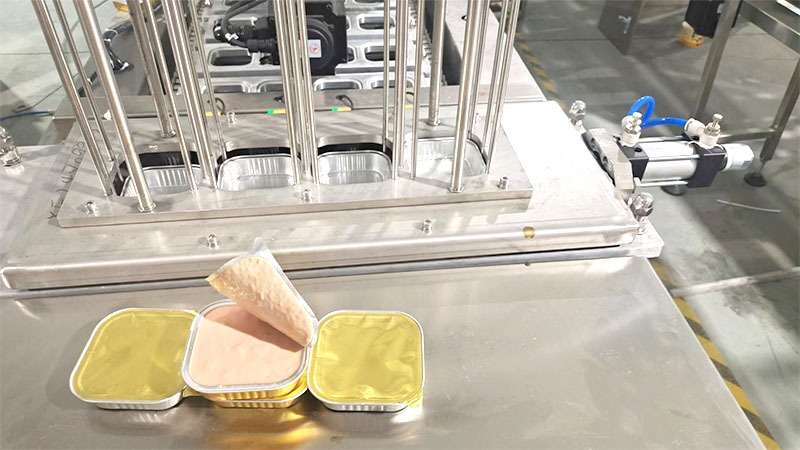

Products are then measured, filled, or counted and placed into primary packaging such as bags, pouches, bottles, or trays. Accuracy and repeatability are critical at this stage to ensure consistent package quality.

After primary packaging, products may be grouped and packed into cartons, cases, or shrink-wrapped bundles. Automatic case packing and palletizing systems are often integrated at this stage.

Quality control systems—such as weight checks, vision inspection, or metal detection—verify compliance before products are labeled and discharged for warehousing or distribution.

By synchronizing each packaging step, an automatic packing line minimizes downtime and reduces speed mismatches between processes, resulting in stable and predictable output.

Automation reduces reliance on manual labor for repetitive tasks, allowing personnel to focus on supervision, quality assurance, and process optimization.

Automated systems deliver uniform packaging quality and support traceability through integrated data collection and inspection systems.

Well-designed packing lines can be upgraded or expanded as production volumes or product ranges increase.

Used for snacks, frozen foods, dairy products, beverages, and condiments where hygiene and consistency are critical.

Ideal for tablets, capsules, medical devices, and regulated products requiring precise control and compliance.

Commonly applied to liquids, creams, powders, and personal care products with frequent packaging changes.

Suitable for bulk materials, hardware, and industrial consumables where durability and throughput are priorities.

Not every product requires a fully automated solution. Low-volume or highly customized packaging may still benefit from semi-automatic systems.

These machines directly handle the product and define packaging accuracy, speed, and format flexibility.

Conveyors ensure smooth material flow between stations and play a key role in overall line efficiency.

PLC and HMI systems coordinate machine timing, monitor performance, and enable fault diagnosis.

Safety guards, emergency stops, and compliance with industry standards are essential for reliable long-term operation.

Key factors include product size, shape, fragility, and required output rate.

Consider whether the line must handle multiple package types or frequent changeovers.

Available floor space, ceiling height, and utilities influence line design and configuration.

Fully automatic lines offer higher efficiency but require greater initial investment. The optimal solution balances performance and return on investment.

The total investment includes not only machines but also system integration, conveyors, and controls.

Proper installation and operator training are critical to achieving expected performance.

Long-term costs include spare parts, preventive maintenance, and potential upgrades.

Understanding these cost components helps avoid underestimating the true investment.

Selecting equipment based on price rather than system compatibility

Ignoring future product or capacity changes

Underestimating maintenance and technical support needs

Choosing suppliers without proven system integration experience

Avoiding these issues can significantly improve project outcomes.

An automatic packing line can deliver substantial efficiency, consistency, and scalability benefits—but only when it aligns with your production goals, product characteristics, and operational capabilities.

Rather than viewing automation as a one-size-fits-all solution, manufacturers should evaluate their current challenges and long-term strategy to determine the most appropriate level of automation.

Choosing the right automatic packing line often requires more than general information—it requires a solution tailored to your product, production capacity, and factory layout.

Yijianuo Machinery specializes in designing and manufacturing custom automatic packing line solutions for a wide range of industries, including food, beverage, daily chemicals, and industrial products. Rather than offering one-size-fits-all systems, Yijianuo focuses on practical automation that aligns with real production requirements.

If you are evaluating or planning an automatic packing line project, you can explore detailed solutions, configurations, and application examples here:

Automatic Packing Line Solutions by Yijianuo Machinery: https://www.yjnmachinery.com/automatic-packing-line/

Reviewing real system layouts and technical options can help you better understand what level of automation is most suitable for your operation.

What is the difference between an automatic packing line and a packaging machine?

A packaging machine performs a single task, while an automatic packing line integrates multiple machines into a coordinated system.

How long does it take to install an automatic packing line?

Installation time varies based on complexity but typically ranges from several weeks to a few months.

Can an automatic packing line handle multiple product types?

Yes, if designed with flexibility and appropriate changeover features.

What level of operator training is required?

Operators usually require basic training in machine operation, safety, and troubleshooting.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.