In today’s highly competitive food industry, packaging is no longer just about containment — it plays a critical role in food safety, shelf life, branding, and operational efficiency. Among the various packaging solutions available, the food tray sealer machine has become one of the most widely adopted systems for fresh food, ready meals, and retail food products.

From small food startups to large-scale processing plants, businesses are increasingly relying on tray sealing technology to meet stricter hygiene standards, extend product freshness, and improve shelf presentation. However, with different machine types, sealing technologies, and material options available, choosing the right food tray sealer machine can be challenging.

This guide provides a complete and practical overview of food tray sealer machines, covering how they work, the different types available, common applications, and key considerations for selecting the right solution for your food packaging operation in 2025.

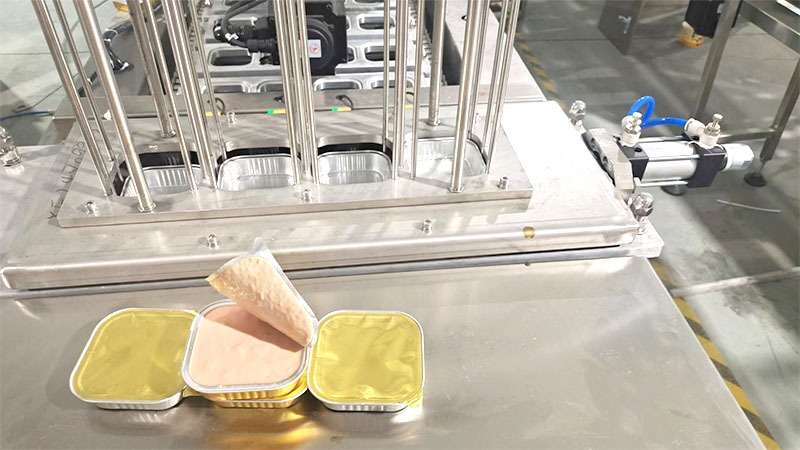

A food tray sealer machine is a packaging device designed to seal food products inside pre-formed trays using a heat-sealed film. The machine applies controlled heat and pressure to bond the sealing film to the tray’s flange, creating a secure and hygienic package.

Food tray sealer machines are commonly used in industries where product freshness, leak prevention, and visual appeal are critical, such as fresh meat, seafood, ready meals, fruits, and dairy products.

At its core, a food tray sealer machine performs three essential functions:

Holds the filled tray in position

Seals a flexible film onto the tray using heat

Cuts excess film for a clean, finished package

Depending on the configuration, the machine may also evacuate air or inject protective gases before sealing, further enhancing product shelf life.

Unlike vacuum pouch machines or thermoforming packaging systems, tray sealers work with rigid or semi-rigid trays, making them ideal for retail-ready food packaging.

Food tray sealer machines have become a standard solution in modern food processing for several reasons:

Enhanced food safety: Airtight sealing reduces contamination risks and supports HACCP-compliant processes.

Extended shelf life: Especially when combined with vacuum or MAP technology.

Improved product presentation: Transparent films and rigid trays enhance shelf appeal.

Operational efficiency: Faster packaging cycles and consistent sealing quality.

Versatility: Suitable for a wide range of food products and tray sizes.

As food safety regulations and consumer expectations continue to rise, tray sealing has become an essential packaging method rather than an optional upgrade.

Understanding how a food tray sealer machine operates helps businesses evaluate performance, efficiency, and suitability for specific food products. While machine designs vary, the basic working process remains consistent across most models.

A typical food tray sealing process includes the following steps:

Tray Loading

Filled trays are placed manually or automatically into the machine’s mold area.

Tray Positioning

The tray is precisely aligned to ensure uniform sealing along the flange.

Film Feeding

The sealing film is drawn from a roll and positioned over the tray.

Sealing Operation

Heat and pressure are applied to bond the film to the tray surface.

Film Cutting

Excess film is cut, leaving a clean and professional edge.

Finished Product Output

The sealed tray is released for labeling, inspection, or secondary packaging.

For machines equipped with vacuum or MAP functions, air evacuation and gas flushing occur before the sealing step.

A food tray sealer machine consists of several critical components that ensure reliable sealing performance:

Sealing Mold

Custom-designed to match specific tray sizes and shapes.

Heating Plate

Provides consistent and controlled sealing temperature.

Film Transport System

Ensures smooth and accurate film feeding.

Cutting System

Trims excess film cleanly after sealing.

Control System (PLC & HMI)

Allows operators to adjust sealing parameters, temperature, and cycle time.

High-quality machines focus on precise temperature control and uniform pressure distribution, which are essential for strong seals and leak prevention.

Selecting the right packaging materials is just as important as choosing the food tray sealer machine itself. Even the most advanced sealing equipment cannot deliver consistent results if the tray and film materials are incompatible. For food manufacturers, understanding material options helps reduce sealing failures, improve shelf life, and ensure stable long-term production.

Experienced equipment suppliers such as Yijianuo Machinery often support customers not only with machines, but also with material compatibility guidance, helping avoid costly trial-and-error during production setup.

Food trays are typically made from rigid or semi-rigid materials designed to withstand heat, pressure, and transportation stress.

PP (Polypropylene) trays are widely used due to their heat resistance and affordability. They are suitable for ready meals, fresh food, and products requiring reheating.

PET trays offer good transparency and rigidity, making them popular for fresh food and retail display packaging. PET trays are often chosen when visual appeal is a priority.

CPET trays are designed for high-temperature applications such as oven-ready meals. Their durability and heat resistance make them suitable for both chilled and frozen products.

Aluminum trays are commonly used for bakery products, cooked meals, and airline catering. While strong and heat-resistant, aluminum trays require proper sealing films to ensure reliable results.

A flexible food tray sealer machine must be able to handle multiple tray materials and sizes, especially for manufacturers producing diverse product lines. Yijianuo Machinery focuses on adaptable mold designs that support various tray types without complex changeovers.

Sealing film selection directly affects seal strength, leak resistance, and consumer experience.

Peelable films allow consumers to open packages easily without tearing, making them popular for retail food products.

Non-peelable films provide stronger seals and are often used for industrial or export packaging where durability is critical.

High-barrier films are commonly used in MAP food tray sealer machines to help maintain internal atmosphere stability and extend shelf life.

Rather than specifying exact technical parameters, food producers typically evaluate films based on compatibility, reliability, and consistency — areas where machine-film matching plays a crucial role.

One of the most common causes of sealing issues is mismatched tray and film materials. Poor compatibility can lead to weak seals, leakage, or inconsistent packaging quality.

By working with manufacturers that understand both equipment and packaging materials, businesses can significantly reduce setup time and production risks. Yijianuo Machinery frequently assists customers in testing tray and film combinations to ensure stable sealing performance before full-scale production.

Modified Atmosphere Packaging (MAP) has become a key technology in modern food tray sealing, particularly for fresh and perishable food products. While not every product requires MAP, understanding its benefits helps food manufacturers make informed decisions about investing in advanced tray sealing systems.

MAP involves replacing the air inside a food tray with a controlled gas mixture before sealing. This process helps slow down spoilage and preserve product quality during storage and transportation.

In a MAP food tray sealer machine, gas flushing and sealing are integrated into a single, controlled packaging cycle, ensuring consistency and efficiency.

The commercial advantages of MAP tray sealing include:

Extended shelf life, reducing product waste

Improved product appearance, especially for fresh meat and produce

Greater distribution flexibility, enabling wider market reach

For businesses supplying supermarkets or export markets, MAP tray sealing often becomes a strategic investment rather than a technical upgrade.

MAP is commonly used for fresh meat, seafood, ready meals, and certain produce items. However, not all products require this technology. Over-packaging can increase costs without delivering proportional benefits.

Manufacturers like Yijianuo Machinery support customers by evaluating product requirements first, then recommending whether standard sealing, vacuum sealing, or MAP solutions are most appropriate.

Choosing the right food tray sealer machine is not only a technical decision but also a long-term business strategy. The wrong choice can limit production flexibility, while the right solution supports growth and operational efficiency.

When evaluating food tray sealer machines, food producers should consider:

Production volume and scalability

Variety of tray sizes and shapes

Automation requirements

Packaging technology needs (standard, vacuum, or MAP)

Available floor space and workflow integration

Budget and expected return on investment

Rather than focusing solely on machine specifications, many successful buyers prioritize supplier experience and support capabilities.

Common mistakes include underestimating future production needs, choosing machines with limited mold compatibility, or focusing on price over long-term reliability.

Yijianuo Machinery addresses these challenges by offering customizable configurations and practical consultation, helping customers select machines that remain suitable as their business evolves.

When evaluating a food tray sealer machine, price is often one of the first questions buyers ask. However, focusing only on the initial purchase cost can be misleading. In reality, the true value of a tray sealing machine lies in its long-term operating cost, flexibility, and production efficiency.

Well-designed food tray sealer machines are not necessarily the most expensive ones — they are the ones that deliver stable performance while keeping total ownership costs under control.

Several factors influence the cost of a food tray sealer machine, including:

Level of automation (manual, semi-automatic, or fully automatic)

Packaging technology (standard sealing, vacuum, or MAP)

Mold design and tray compatibility

Production capacity and configuration flexibility

After-sales support and technical assistance

Rather than offering fixed, over-engineered solutions, manufacturers that focus on practical customization are often able to deliver more cost-effective equipment without compromising reliability.

Many food producers assume that advanced tray sealing solutions always come with a high price tag. In practice, machines designed around actual production needs often provide better value than standardized systems with unnecessary features.

Yijianuo Machinery follows this approach by working closely with customers to define realistic packaging requirements first, then configuring food tray sealer machines accordingly. This helps avoid unnecessary investment while maintaining consistent sealing quality and production stability.

For businesses seeking competitive pricing with professional-grade performance, this balance between cost and capability can make a significant difference.

A competitively priced food tray sealer machine should also help reduce:

Labor costs through efficient operation

Product loss caused by poor sealing

Downtime related to maintenance or adjustments

By focusing on reliability and adaptability, manufacturers like Yijianuo Machinery help customers achieve a lower total cost of ownership over the machine’s service life.

If you are comparing different food tray sealer machine options and want a solution that balances performance and cost, contacting Yijianuo Machinery for a tailored recommendation can be a practical first step.

In food packaging operations, consistent machine performance is closely linked to proper maintenance and hygiene practices. A food tray sealer machine must be easy to clean, simple to maintain, and capable of supporting food safety compliance over long-term use.

Regular inspection and basic maintenance help ensure stable sealing quality and extend machine lifespan. Most food tray sealer machines are designed for straightforward daily checks, such as cleaning sealing areas and monitoring film feeding components.

Machines built with durable structures and accessible components reduce maintenance time and minimize production interruptions — an important consideration for food processors operating under tight schedules.

Food tray sealer machines are commonly used in environments with strict hygiene requirements. Smooth surfaces, accessible sealing areas, and practical machine layouts support efficient cleaning and sanitation procedures.

Manufacturers with experience in food industry equipment design understand the importance of cleanability and operational simplicity, helping customers maintain hygiene standards without complex disassembly.

While specific regulations vary by region, food tray sealer machines must support consistent, hygienic packaging processes. Stable sealing performance helps reduce contamination risks and supports food safety management systems.

Yijianuo Machinery designs tray sealing equipment with food packaging applications in mind, offering solutions that align with industry hygiene expectations and real-world production needs.

For food businesses looking for reliable equipment that supports safe and efficient packaging operations, discussing maintenance and hygiene requirements with Yijianuo Machinery can help ensure long-term compliance and performance.

As food packaging continues to evolve, food tray sealer machines are also advancing to meet new market demands. Future trends focus less on complexity and more on efficiency, flexibility, and sustainability.

Key developments include:

Greater automation with simplified operation

Improved compatibility with sustainable packaging materials

Modular machine designs for easier upgrades

Enhanced control systems for consistent sealing quality

Manufacturers that invest in practical innovation — rather than unnecessary complexity — are better positioned to support food producers facing changing market requirements.

Choosing the right food tray sealer machine is a strategic decision that affects product quality, production efficiency, and long-term operating costs. A well-matched tray sealing solution helps food businesses improve shelf life, reduce waste, and enhance brand presentation.

Rather than pursuing the most expensive option, many successful food producers focus on reliable performance, flexible configuration, and cost-effective design. This approach allows them to scale production while maintaining consistent packaging quality.

Yijianuo Machinery supports food businesses with practical, customizable food tray sealer machine solutions designed to balance performance and investment efficiency.

If you are planning to upgrade or expand your tray sealing operations, contacting Yijianuo Machinery can help you explore a cost-effective solution tailored to your specific food packaging needs.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.