The Ice Cube Cup is a modern packaging format changing how chilled beverages are prepared and sold. Instead of serving loose ice in an open cup, the Ice Cube Cup packages pre-filled ice or chilled components inside a single sealed container that is ready-to-serve. This shift is driven by consumers’ demand for convenience, hygiene and striking presentation.

Ready-to-serve Ice Cube Cups reduce service time and handling, improve portion control, and offer a hygienic, visually consistent product for grab-and-go consumers. As the market becomes more image-driven (social media, display shelves in convenience stores), the ability to present a neat, sealed chilled beverage is a powerful differentiator.

Learn more about packaging innovations and single-use sealed cups from ICE³ Innovation: ICE³ Innovation — Sealed Cups.

Coffee shops, smoothie bars and juice brands adopt Ice Cube Cups because the format addresses operational and marketing needs simultaneously. From a back-of-house perspective, sealed ice cups simplify service workflows and minimize waste. From a front-of-house perspective, they enhance hygiene perception and offer a premium look that can command higher price points.

For regional trend context, see reporting on convenience-store iced drink growth in Asia: Reuters — Chinese convenience stores and iced drinks.

Producing Ice Cube Cups at scale involves a predictable flow of operations: cup forming or feeding, precise filling of ice or chilled components, and leak-proof sealing. Modern production lines automate these steps to secure hygiene and throughput.

Cups may be supplied pre-moulded or formed in-line. Automated feeders place each empty cup in sequence for filling. Choice of cup material (PP, PET, PS) affects sealing method and thermal performance.

Filling systems are engineered to handle solid ice, crushed ice, or combinations of ice and liquid. Volumetric and mechanical dispensers ensure that each cup receives the correct amount of ice—minimizing weight variance and product shrinkage.

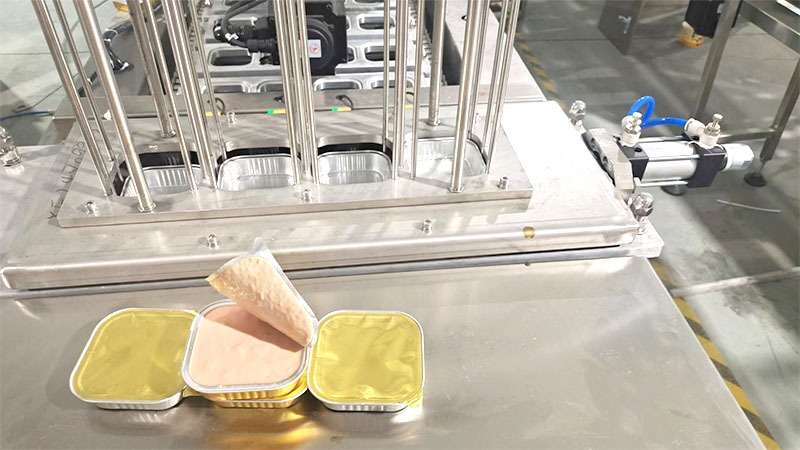

After filling, the cup is sealed with film or a lid using thermal or heat-seal technology. Reliable sealing prevents leakage and contamination and enables safe cold-chain handling and retail distribution.

A purpose-built ice cube cup filling and sealing machine integrates cup feeding, precision filling, sealing, and ejection into a single workflow. These machines are the backbone of any scalable Ice Cube Cup operation: they increase throughput, reduce manual labor and enforce consistent hygiene standards.

Several converging trends make the Ice Cube Cup an attractive business opportunity:

Consumers increasingly favor ready-to-serve options at retail, fueling demand for grab-and-go chilled products in cafes, convenience stores and foodservice outlets.

New materials and seal technologies enable better thermal performance and extended shelf life. Packaging innovations also enable premium experiences (layered drinks, visual merchandising).

As brands scale Ice Cube Cup SKUs, automated filling & sealing systems become essential to meet throughput targets and meet food-safety standards without ballooning labor cost.

See an example of integrated cup-ice production lines: Icemedal — one-stop cup ice production.

Setting up a reliable production line requires selecting the right combination of equipment, establishing hygiene and QC processes, and planning for cold-chain logistics. Below are practical considerations for brands and contract manufacturers.

When evaluating machines, compare the following:

The right equipment partner can determine uptime, product quality and the speed at which you can scale. Prioritize suppliers who provide transparent performance data, customization ability, and robust after-sales support.

Ready to scale Ice Cube Cup production?

Explore demo options and production assessments with experienced filling & sealing machine providers — request a consultation.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.