| Packing container: | Paper cup |

|---|---|

| Drive method: | Electrical drived |

| Production Capacity: | 80-150pcs/hour |

| Process requirements: | Filling, sealing and shrink packing |

| Suitable cup size: | Width: 20-200mm; Height: 50-200mm |

| Suitalbe film: | Precut foil film |

| Sealing temperature: | 0~400 degrees adjustable |

| Machine Voltage: | 380 50HZ or customized |

| Control system: | PLC + Touch screen |

| Air pressure: | 0.6-0.8Mpa |

*We respect your confidentiality and all information are protected.

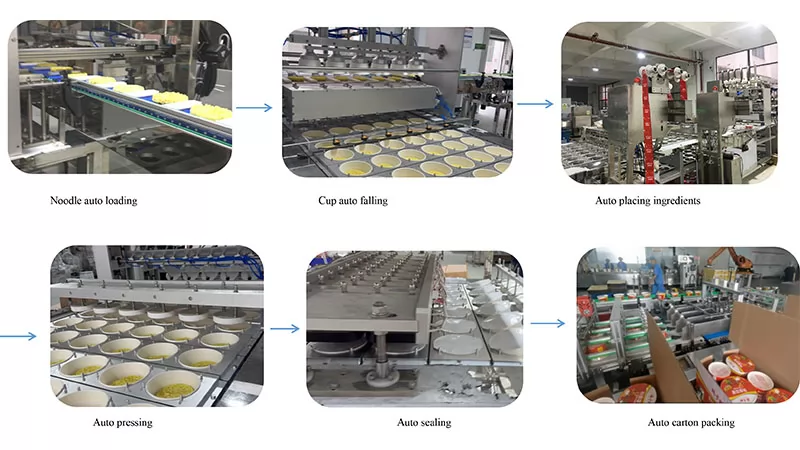

The fully automatic instant noodle cup packaging line is a production line used for automatic packaging of instant noodle cups.

Customized instant noodle cup packinincludes noodle auto loading, cup auto falling, auto placing the ingredients, auto placing foil film, auto sealing, auto delivery to the flow packing machine and heating furnance, auto carton packing.

Instant noodle cup supply system: usually composed of silos, conveying devices and positioning mechanisms. The silos are used to store a large number of instant noodle cups, the conveying devices transport the instant noodle cups from the silos to the packaging area, and the positioning mechanisms ensure that the instant noodle cups maintain the correct position and direction during the transportation process.

Noodle delivery system: accurately place the prepared noodle blocks into the instant noodle cups.

Seasoning package delivery system: accurately place various seasoning packages into the instant noodle cups. Generally, there are seasoning package storage devices, sorting mechanisms and delivery devices.

Packaging material supply system: provides materials required for instant noodle cup packaging, such as cup lids, shrink films, etc. Usually stored in rolls on the material rack, the packaging materials are accurately delivered to the packaging position through the tension control device and the feeding mechanism.

Sealing system: seal the instant noodle cups with noodle blocks and seasoning packages to ensure sealing.

The advantages of fully automatic instant noodle cup packing line:

1) Improve production efficiency: It can realize the full automation of instant noodle cup packaging, greatly reduce the manual operation links, improve the packaging speed and output, and meet the needs of large-scale production.

Ensure packaging quality: Through precise metering and positioning systems, as well as stable sealing and labeling technologies, it can ensure the consistent packaging quality of each instant noodle cup and reduce the production of defective packaging products.

2) Reduce labor costs: Reduce dependence on manual labor, reduce the company's labor costs and labor intensity, and also reduce errors caused by factors such as manual operation fatigue.

Improve corporate image: Automated production equipment reflects the company's modern production level and technical strength, and helps to enhance the company's image and competitiveness in the market.

3) Easy to manage and maintain: It is usually equipped with advanced control systems and monitoring equipment, which is convenient for operators to centrally control and manage the production line, and also convenient for equipment maintenance and troubleshooting.