In the food processing industry, cup-packaged sauces are widely favored by consumers due to their convenience and hygiene. As a crucial piece of equipment for sauce packaging, the importance of cup-filling machines for sauces is self-evident. To help you better use and maintain this equipment, we provide the following usage and maintenance guidelines to help you improve production efficiency and ensure the long-term stable operation of the equipment.

I. Precise Operation to Ensure Filling Quality

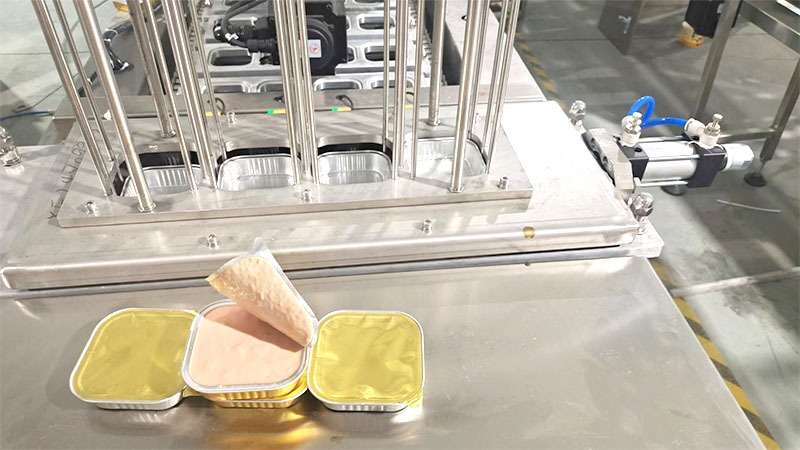

Correct operation is the prerequisite for ensuring filling quality. Our cup-type sauce filling machine features a user-friendly touchscreen interface. Before operation, please ensure you have thoroughly read the instruction manual and follow the steps accordingly. Pay attention to adjusting the filling volume and speed to suit different sauce characteristics and packaging requirements.

II. Regular Cleaning to Ensure Food Safety

Cleaning is crucial for the maintenance of food packaging equipment. Regularly cleaning the filling machine, especially the parts that come into direct contact with the sauce, prevents bacterial growth and ensures food safety. When cleaning, please use a dedicated cleaning agent and ensure all parts are thoroughly dry before reassembly.

III. Lubrication and Maintenance to Extend Equipment Lifespan

Regularly lubricating the moving parts of the filling machine reduces wear and extends the equipment's service life. Check the lubrication system regularly to ensure the lubricant is clean and sufficient.

IV. Troubleshooting and Timely Problem Solving

Equipment may inevitably experience malfunctions during use. Our filling machine is equipped with a fault diagnosis system that provides timely alarms and displays fault codes when problems occur. When a malfunction occurs, please refer to the instruction manual for troubleshooting, or contact our professional technical personnel for repair.

V. Spare Parts Replacement to Maintain Equipment Performance

Regularly inspect the wear parts of the filling machine, such as seals, pumps, and valves. Replace worn parts promptly to maintain the equipment's high performance.

VI. Training and Support to Enhance Operating Skills

We provide professional operation training and after-sales service support to help your operators improve their operating skills and better manage and maintain the equipment.

Conclusion:

The correct use and maintenance of the cup-type sauce filling machine are key to improving production efficiency and ensuring product quality. By following these guidelines, you can not only maximize equipment performance but also effectively reduce maintenance costs and maximize production efficiency. We are always committed to providing you with high-quality products and services, and working together to create a better future.