In today’s fast-paced food and beverage industry, efficiency, hygiene, and product consistency are key factors that determine a brand’s success. This is where Cup Filling and Sealing Machines play a crucial role. These advanced packaging systems automate the process of filling liquid, semi-liquid, or viscous products—such as yogurt, juice, sauces, and desserts—into pre-formed cups with precise sealing, ensuring product integrity and extended shelf life.

As demand for ready-to-eat and convenience foods continues to grow globally, manufacturers are investing in high-performance filling and sealing solutions that combine accuracy, reliability, and easy maintenance. In this article, we’ve compiled a list of the Top 10 Cup Filling and Sealing Machine Manufacturers in the World (2025). Each company listed here stands out for its technological innovation, product quality, and commitment to supporting modern production needs. Whether you are expanding an existing production line or starting a new project, this guide will help you identify the right partner for your automation requirements.

The List of Top 10 Packaging Machine Manufacturers in US 2025

Yijianuo Machinery is a leading manufacturer of cup filling and sealing machines, headquartered in Wuhan, China. Since its establishment in 2012, Yijianuo has established itself as a trusted provider of automated packaging machinery solutions. With over 13 years of experience in the design, R&D, manufacturing, and sales of filling and sealing machines, the company excels in providing customized packaging lines for the food, beverage, pharmaceutical, and daily chemical industries. As a professional cup filling and sealing machine manufacturer, Yijianuo integrates advanced automatic filling and sealing equipment to ensure hygienic, efficient, and precise operation.

Yijianuo is experiencing strong growth, with a team of over 160 professionals, including a core R&D team of graduate-level engineers, to drive innovation and customization. With five production lines and 38 advanced machines, the company launches six new products annually, specializing in light customization, sample processing, and on-demand production. The company is ISO9001 and CE certified. This growth is driven by a 100% on-time delivery rate, stringent quality control from raw material traceability to finished product inspection, and a strong supply chain comprised of 16 partners. As a versatile cup filling and sealing machine manufacturer committed to building long-term partnerships with customers through superior service and technical support, Yijianuo serves global markets including North America, South America, and the Middle East.

Ejianuo's factory status reflects its operational excellence, with its 10,136-square-meter facility in Wuhan dedicated to comprehensive machining and fully customized production. This state-of-the-art facility boasts a dedicated quality assurance team of five inspectors and provides responsive after-sales service, including on-site technical assistance and equipment maintenance, to overseas warehouses, ensuring seamless integration of its global cup filling and sealing machine solutions.

Best Products:

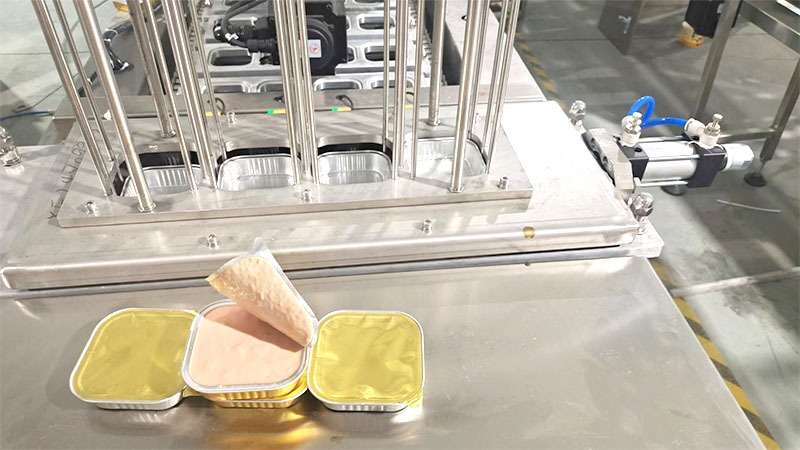

Automatic Cup Filling Sealing Machine: Offers integrated filling, sealing, and capping services for precise packaging of liquids and semi-solids.

Plastic Cup Sealing Machine: Provides high-speed sealing services for plastic containers in food and beverage applications.

Jelly Cup Filling and Sealing Machine: Delivers automated filling and sealing services for viscous products like jelly and sauces.

Ice Cube Cup Filling and Sealing Machine: Ensures efficient filling and sealing services for frozen treats and ice products.

R.A. Jones, a leading cup filling and sealing machine manufacturer with over 120 years of production experience in the packaging industry, was founded in 1905 in Covington, Kentucky, initially as a soap packaging company that pioneered the development of automated wrapping machinery. The company's first soap packaging machine was built in 1912, marking the beginning of its expertise in filling and sealing technologies that evolved to include innovative cup filling systems for wet and dry products. Through strategic acquisitions and relentless innovation, R.A. Jones has grown into a multinational cup filling and sealing machine manufacturer, incorporating brands like Holmatic in the 1950s for advanced filling and sealing equipment and Autoprod in the 2000s for specialized dairy cup filling solutions, enabling it to offer comprehensive cup filling and sealing machine solutions with capacities ranging from 100 to 840 cups per minute. Its development trajectory reflects a commitment to technological advancement, including the introduction of high-speed vertical form fill and seal machines like the Pouch King series, integration of robotics for enhanced cup filling and sealing efficiency, and adoption of sustainable practices such as modified atmosphere packaging (MAP) systems to extend shelf life in cup sealing applications. Remaining family-owned until 1998, R.A. Jones was acquired by Barry-Wehmiller International and later integrated into the Coesia Group in 2000, fostering global expansion and continuous R&D in cup filling and sealing machine manufacturing with over 80 in-house engineers driving upgrades for straight and tapered walled cups, including round, oval, and square formats. Today, as a key player in cup filling and sealing machine solutions, the company maintains state-of-the-art factories, including its relocated headquarters in Covington, Kentucky—recognized as one of the top 10 manufacturing facilities by industry standards—and a major production hub in Davenport, Iowa, where Holmatic, KartridgPak, and Autoprod operations are consolidated for efficient cup filling, sealing, and overcapping machine assembly and testing. These facilities support ongoing development in energy-efficient cup sealing technologies and after-market services, ensuring reliable performance for global clients in food, beverage, and dairy sectors while emphasizing eco-friendly cup filling and sealing machine designs to reduce environmental impact.

Best Products:

Cup Filling Machine: volumetric and auger filling for liquids, powders, and semi-solids in preformed cups

Cup Sealing Machine: heat sealing and ultrasonic sealing for hermetic closure on various cup materials

Overcapping Machine: automated lidding and capping for enhanced product protection post-filling and sealing

ZONESUN Technology Limited, a leading cup filling and sealing machine manufacturer, was established in 2014 as a modern high-tech enterprise in Foshan, Guangdong Province, China, with a registered capital of 10 million yuan. Specializing in the research, development, production, sales, and technical services of advanced filling machinery, capping machines, labeling machines, packaging machines, and automated production lines, the company has built extensive production experience since its inception, rapidly expanding through five relocations and seven business scope enlargements to accommodate surging demand in the cup filling and sealing machine sector. From 2017 to 2019, ZONESUN secured trademark registrations and national intellectual property invention patents, underscoring its commitment to innovation in cup filling and sealing machine manufacturing. Currently boasting over 200 staff members across high-quality technical research and development, marketing, and professional management teams, the company operates two subsidiaries and partners with Guangdong Shanghang Technology Limited, implementing an integrated online-offline strategy to drive international growth. Its products, including premium cup filling and sealing machines, are exported to key markets such as the United States, Canada, Italy, Brazil, Russia, and various European countries, reflecting robust development status fueled by diversified management, continuous innovation, and a "people-oriented" philosophy that prioritizes employee growth and all-staff insurance. The factory status remains impressive, with an in-house elevator plant spanning more than 50,000 square meters and equipped with over 300 processing sets, enabling efficient production of reliable cup filling and sealing machines tailored for diverse packaging needs.

Best Products:

Plastic Cup Filling and Sealing Machine: Automates feeding, filling, sealing, and discharging plastic cups.

Rotary Automatic Plastic Marinara Sauce Cup Filling Sealing Machine: Automates feeding, filling, sealing, and discharging plastic cups.

Automatic Liquid Premade Pouch Filling Sealing Machine: Ensures airtight seals for various products in pouches.

Automatic Plastic Tube Filler and Sealer Machine: Designed for efficient tube packaging.

Automatic Glass Ampoule Liquid Filling Sealing Machine: Uses precision ceramic pumps for small-capacity filling of liquids into ampoules.

Roberts Technology Group, Inc. (RTG), established in 1995 and headquartered in Chalfont, Pennsylvania, stands as a premier North American supplier and distributor of advanced cup filling and sealing machine solutions, processing and packaging machinery, and flexible packaging films. With over 25 years of production experience in the packaging industry, RTG has evolved from a specialized distributor into a comprehensive partner for businesses seeking reliable cup filling machine and sealing machine technologies, offering expert guidance, onsite assistance, client education, maintenance services, turn-key installations, and staff training to streamline operations across sectors like food, cosmetics, pharmaceuticals, dairy, bakery, and ready meals. The company's development status reflects steady growth through exclusive partnerships with renowned manufacturers such as ILPRA America and SOLLAS America, enabling access to high-quality, low-cycle-time equipment that minimizes downtime and supports scalability from small-batch to high-throughput production, all while emphasizing preventative care, expedited repairs, and seamless integration for enhanced efficiency in cup filling and sealing processes. Currently, RTG does not operate its own manufacturing facilities but leverages ISO-certified partner factories to deliver durable, IP65 wash-down rated machines constructed from 304/316 grade stainless steel, featuring high automation, multi-tasking capabilities, and variability for diverse package sizes—from small cups to large containers—integrated with systems like conveyor belts, checkweighers, and metal detectors for end-to-end automated cup filling and sealing workflows.

Best Products:

Volumetric Cup Filling Machine: precise filling services for dips, sauces, and liquids in small cups

Yogurt Cup Filling Sealing Machine: all-in-one filling and sealing solutions for dairy products with enhanced safety and versatility

Tray Sealer: heat seal and modified atmosphere packaging services for food trays including meat, poultry, and produce

Fill Sealer: automated filling and sealing integration for ready meals, pasta, and seafood containers

Thermoforming Sealing Machine: custom thermoforming and vacuum skin packaging services for bakery and confectionery items

Modern Packaging Machinery, Inc., a premier cup filling and sealing machine manufacturer, has been at the forefront of automated packaging solutions since its establishment in 1989 by co-founders Syed (Zaki) Hossain and Jaroslaw (Jerry) Dabek. With over 30 years of production experience in designing and building precision cup filling and sealing machines, the company has delivered approximately 1,100 units worldwide, specializing in servo- and cam-driven systems for denesting, loading, filling, foil or plastic lid sealing, and overcapping technologies tailored to dry powders, liquids, semi-viscous, and viscous products in preformed cups and trays. As a leading cup filling and sealing machine manufacturer for the food, beverage, dairy, cosmetic, and pharmaceutical industries, Modern's development trajectory reflects robust growth, culminating in its acquisition by ProMach in 2020, which expanded its rotary and inline filling capabilities for viscous food and dairy applications while enhancing its portfolio of ultra-clean, modified atmosphere packaging (MAP), and aseptic cup filling and sealing systems compliant with USDA, UL, and 3A dairy standards. Today, the company maintains a strong development status with ongoing innovation in compact, stainless steel-constructed cup filling and sealing machines that support speeds from 30 to 600 units per minute and filling volumes from 0.25 ounces to 10 pounds, backed by a dedicated team of over 100 employees, including 17 mechanical and electrical engineers and 12 service technicians operating on a two-shift schedule. Its factory status underscores operational excellence, housed in a 60,000 square foot manufacturing facility in Deer Park, New York, where 95% of components for cup filling and sealing machines are produced in-house to ensure quality control, rapid customization, and reliable 24-hour production readiness as a trusted cup filling and sealing machine manufacturer.

Best Products:

Inline Cup Filling and Sealing Machines: Custom engineering and integration for high-speed filling from 30-600 units per minute.

Rotary Cup Filling and Sealing Machines: Compact design with denesting, filling, and lidding up to 40-100 cups per minute.

Tray Filling and Sealing Systems: Heat sealing and overcapping add-ons for modified atmosphere packaging.

Die Cut Foil Lid Sealing Equipment: Precision sealing solutions for preformed cups and trays with clean-in-place options.

World Cup Packaging is a leading cup filling and sealing machine manufacturer with over 30 years of production experience in designing and building specialized packaging machinery for filling and sealing cups, tubs, and trays with a wide range of products, including liquids, granules, and portion-controlled items for the food industry. Originally founded in 1992 as Star Packaging by Bob Seay in South Beloit, Illinois, the company underwent a significant rebranding and partnership expansion to become World Cup Packaging, focusing on innovative cup filling machines and rotary sealing solutions that ensure precise portioning and hermetic seals for inter-stackable cups and containers. This evolution has positioned it as a trusted provider of semi-automatic and fully automatic inline filling machines and rotary cup fillers, emphasizing reliability and customization for high-volume packaging needs in dairy, candies, juices, and other sectors. In terms of development status, World Cup Packaging has demonstrated consistent growth, with business booming leading to a near-doubling of its facility size in 2005 at the South Beloit Industrial Park to accommodate increased demand for cup sealing machines and filling systems. Further expansion occurred in 2012, adding 18,000 square feet to enhance production capabilities for advanced rotary and inline cup filling and sealing machines, which also created 25 new jobs and solidified its role as a key player in the packaging machinery sector. The company's ongoing development reflects a commitment to engineering cutting-edge technology for consistent, accurate filling and sealing operations, supported by in-house design, production, installation, and after-sales services tailored to cup filling and sealing machine users worldwide. Currently, its factory status features a robust manufacturing setup at 14392 De La Tour Drive in South Beloit, IL 61080, operating as a mid-sized facility with a small, dedicated team that leverages expanded infrastructure for efficient assembly of high-output cup filling machines capable of up to 40 indexes per minute, ensuring scalability for rotary sealing and inline filling applications.

Best Products:

Rotary Cup Filling and Sealing Machine: Design, production, and after-sales support

Inline Cup Filling Machine: Installation and customization services

Semi-Automatic Cup Sealing Machine: Engineering and maintenance support

AFPAK, a premier cup filling and sealing machine manufacturer, has been at the forefront of the coffee capsule filling and sealing machine industry since its establishment in 2010, accumulating over 15 years of specialized production experience in developing high-efficiency K-cup filling and sealing machines and related packaging solutions. As a global leader in coffee capsule filling, sealing, and packaging machines, the company has experienced robust development, expanding its offerings to include fully customized rotary K-cup filling and sealing machines capable of achieving up to 300% efficiency improvements and speeds of 200 cups per minute for diverse filling materials like coffee and tea powder. This growth is driven by a commitment to state-of-the-art technology and one-stop K-cup filling, sealing, and packaging machine services, serving clients worldwide from its ISO-certified manufacturing facility in Shanghai, China, where all cup filling and sealing machines are produced in strict compliance with industrial standards to ensure reliability and precision in coffee capsule packaging operations.

Best Products:

K-Cup Filling and Sealing Machine: customized filling, sealing, and packaging for single-serve coffee and tea pods

Rotary Nespresso Capsule Filling and Sealing Machine: high-speed production of 50-70 cups per minute with versatile material handling

Coffee Capsule Packaging Machine: integrated solutions for empty K-cups, sealing materials, and complete turnkey operations

MIC Machinery, a leading cup filling and sealing machine manufacturer, has established itself as a premier provider of advanced packaging solutions for the food, pharmaceutical, cosmetic, and chemical industries since its founding in 1999 in Changzhou, China. With over 26 years of production experience in designing and manufacturing intelligent filling machines, capping machines, labeling machines, and pretreatment equipment tailored for liquids, creams, pastes, and high-viscosity products, the company has consistently introduced foreign advanced technologies and innovated annually based on client feedback and practical applications. Its development trajectory reflects robust growth: starting with a focus on chemical and agrochemical packaging machines, it expanded into cosmetics, food, and pharmaceuticals by 2010, achieving domestic sales of fifteen million Chinese Yuan; by 2014, it entered international markets, exporting to over 20 countries; overseas sales surged from one and a half million dollars in 2016 to over twenty-five million dollars in 2021 across more than 90 countries, supported by a dedicated technical team that developed specialized lines for e-liquid bottles, syringes, jars, bags, cups, PET bottles, glass bottles, and cans. Holding import/export rights, CE certification, and ISO 9001 compliance, MIC Machinery maintains long-term partnerships with global dealers, emphasizing quality electrical configurations from top brands and precision-engineered mechanical parts to ensure durability and customer satisfaction under the motto "the customer's requirement is our standard."

The company's factory status underscores its operational scale and efficiency, with two specialized workshops: a primary 5,000-square-meter facility in Changzhou's Jintan area for broad production needs, and a 2,000-square-meter dedicated site in the Wujin area at the Wuxi-Changzhou junction, optimized for cosmetics and pharmaceutical cup filling and sealing machine manufacturing. These facilities enable seamless fulfillment of diverse industry demands, from food cup packaging lines expanded in 2018 to beverage filling systems introduced in 2019, all while upholding German-standard production processes for reliability.

Best Products:

Automatic Cup Filling and Sealing Machine: precision filling and sealing services for sauces, mayonnaise, honey, and yogurt in plastic cups at 30-35 cups per minute.

Rotary Cup Filling and Sealing Machine: automated packaging services for dairy and viscous products with controlled viscosity handling and minimal downtime.

Plastic Cup Filling Machine: versatile filling services for liquids, pastes, and creams into cups, jars, and containers across food and cosmetic applications.

CoffeeTec, a leading cup filling and sealing machine manufacturer and global coffee roastery development company, has been serving the coffee industry since its founding in 1972 by Jay Endres, a pioneer with over 44 years of experience in gourmet coffee machinery development, including innovations in roasters, grinders, and quality control instruments. As a full-scale coffee plant equipment manufacturing entity, CoffeeTec specializes in providing comprehensive solutions for cup filling and sealing machine operations, K-Cup packaging systems, and related automation for efficient coffee capsule production, catering to startups, small-scale roasters, and large operations worldwide. The company's development trajectory reflects steady growth, evolving from early industry contributions alongside figures like Alfred Peet and Howard Schultz in the 1970s and 1980s to becoming the largest online retailer and reseller of new and used coffee roasting and packaging equipment, with over 3,000 items in stock sourced from the US, Europe, and Asia. Acquired and led by CEO Scott Plail since November 2017, CoffeeTec has expanded its scope to include financing, consulting, and education services, positioning itself as the "Amazon of the coffee industry" while maintaining in-house engineers to design future cup filling and sealing machine innovations for enhanced production efficiency and scalability. Currently headquartered in Sandpoint, Idaho, with 11-50 employees focused on machinery manufacturing, CoffeeTec operates as a global leader without disclosed specific factory facilities but emphasizes robust sourcing, ongoing partnerships for equipment commissioning, site design, and silo conveyance to support seamless cup filling and sealing machine integration in roasteries.

Best Products:

Rotary K-Cup Filling and Sealing Machine: turnkey production at 50-70 cups per minute with fast changeover for Nespresso and K-Cup capsules.

Single Lane Auto K-Cup Filling and Sealing Machine: entry-level automation handling up to 3000 cups per hour for economical small-scale operations.

Coffee Cup Sealing and Filling Machine: compact manual system for small-batch sealing with durable stainless steel construction.

K-Cup Sealing Machine: precise 2-second foil sealing for reliable capsule integrity and safe operation.

Volumetric Technologies stands as a premier cup filling and sealing machine manufacturer, renowned for its American-made automated liquid filling solutions that enhance production efficiency and precision in volumetric filling processes. With over 30 years of production experience in designing and fabricating custom thick and thin liquid filling machines, the company has established itself as an innovative leader within the Excelis Packaging Automation family of brands, specializing in food packaging equipment and beverage filling systems that address challenges like inaccurate fill volumes and messy operations. Their development status reflects ongoing advancements in servo-driven cup filling and sealing machines, enabling scalable, end-to-end production line integrations for industries including food, beverage, cosmetics, and industrial products, with a focus on minimizing downtime and maximizing output through precision-built, customizable equipment. The factory status underscores robust American manufacturing capabilities, producing durable rotary cup filling machines and inline cup fillers that are built to last, supported by a well-stocked parts department, on-site service technicians, and comprehensive field support to ensure seamless volumetric cup filling operations.

Best Products:

Rotary Cup Filling Machine: automated rotation for fill, seal, and lid application on stackable cups

Inline Cup Filling Machine: high-volume piston-based fill, seal, and lid for stackable containers

Selecting the right Cup Filling and Sealing Machine manufacturer can significantly impact your production efficiency, product quality, and long-term operational costs. The companies highlighted in this list represent the global leaders driving innovation in filling and sealing automation for 2025. From modular systems to fully customized turnkey solutions, these manufacturers continue to redefine standards of performance, sanitation, and precision across industries.

If you’re looking for a reliable and cost-effective partner in this field, Yijianuo Machinery is an excellent choice. With years of experience in developing advanced Cup Filling and Sealing Machines, Yijianuo offers tailored solutions that meet the diverse needs of dairy, beverage, and food manufacturers worldwide. Their machines are designed for high accuracy, easy operation, and compliance with international hygiene standards.

Contact Yijianuo Machinery today to explore how their cutting-edge filling and sealing solutions can streamline your production line and elevate your product quality in 2025 and beyond.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.