In 2025, the filling and sealing machine industry in the United States continues to evolve rapidly as manufacturers seek higher automation, cleaner production environments, and sustainable packaging solutions. A Filling and Sealing Machine Factory today is more than just a machinery producer—it is a strategic partner that supports product quality, compliance, and operational efficiency.

Across industries such as food and beverage, pharmaceuticals, cosmetics, and household products, American factories have established a strong reputation for engineering reliability, precise filling accuracy, and robust sealing performance. These U.S.-based manufacturers also lead in adopting smart technologies like real-time monitoring, servo-driven controls, and Industry 4.0 integration.

This article highlights the Top 10 Filling and Sealing Machine Factories in the US 2025, focusing on their core strengths, product innovations, and how they are shaping the next generation of automated packaging solutions. Whether you are a small-scale producer or a global brand, understanding the capabilities of these factories will help you make an informed investment decision.

The demand for filling and sealing machine in the United States has been growing steadily, driven by industries such as food and beverages, pharmaceuticals, cosmetics, and household products. In 2025, choosing a USA-based factory for your filling and sealing equipment offers unique advantages compared with importing machines from overseas.

Domestic manufacturing allows businesses to reduce long shipping times and import-related delays. U.S. factories can deliver equipment more quickly, enabling companies to respond to new product launches or seasonal demand without long wait periods. This agility is crucial for consumer-driven industries like ready-to-eat meals, dairy products, and nutraceuticals.

Factories in the U.S. design and build machines in compliance with FDA, USDA, and OSHA requirements. This ensures that equipment used for food and pharmaceutical packaging meets the strictest safety and hygiene standards. Companies importing machines often face costly modifications to achieve compliance, whereas U.S.-built systems are ready for immediate integration.

One of the main challenges with imported machines is the lack of timely technical assistance. U.S. manufacturers provide on-site installation, operator training, and rapid spare parts delivery. Many factories maintain nationwide service networks, reducing downtime and protecting production efficiency.

Choosing an American factory is not just about machinery—it’s also about brand reputation. For consumer goods companies, working with U.S. equipment suppliers can strengthen trust, since “Made in USA” is often associated with reliability, safety, and quality. In highly competitive markets, this reputation becomes part of a company’s value chain.

Many U.S.-based machine builders are pioneers in automation, robotics, and Industry 4.0 technologies. From predictive maintenance systems to eco-friendly sealing techniques, local manufacturers are often first to integrate cutting-edge innovations. This helps production facilities maintain long-term competitiveness while reducing labor and energy costs.

Overview:

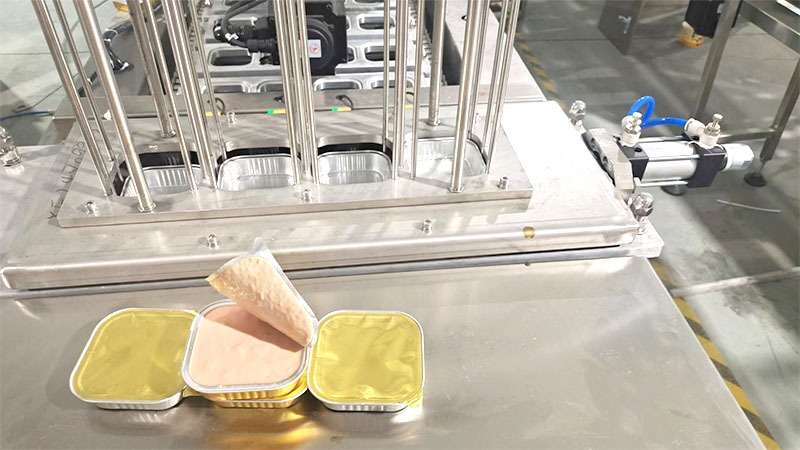

Wuhan Yijianuo Machinery (often shown as Yijianuo / Yinuo on trade platforms) is a packaging-equipment manufacturer that designs and supplies automatic filling, sealing and thermoforming systems. The company publishes product lines for cup/box sealing, spout pouch filling & capping, thermoforming vacuum packaging and other integrated packaging lines; its corporate/product pages and trade listings identify Wuhan (Hubei, China) as the company base.

Strengths:

Wide product breadth for food & dairy applications — Yijianuo lists cup fillers/sealers and dairy/ready-meal equipment among its core offerings, which makes it a practical choice for companies seeking single-source equipment for cup and tray formats.

Cost-competitive export focus — the company markets machines through Alibaba and other export channels, which is useful for buyers seeking competitively priced turnkey units or starter production lines.

Product customization and integrated functions — Yijianuo promotes combined functions (filling, sealing, capping, labeling, coding, CIP options), which helps with short-run flexibility and turnkey line delivery.

Specializations:

Cup/cup-sealer machines (yogurt, dairy, ready-meals) — high-speed cup filling and lid sealing.

Thermoforming & vacuum/skin packaging machines for MAP and vacuum packaging.

Spout pouch filling & capping and other flexible-package solutions for liquid and semi-liquid products.

Overview:

Matrix Packaging Machinery is a U.S.-based manufacturer of flexible-packaging equipment—best known for vertical form-fill-seal (VFFS) systems and a range of pouch and stick-pack machines. Many food, pet-care, nutraceutical and non-food lines rely on Matrix as a filling and sealing machine factory for compact, high-throughput VFFS and pre-made-pouch solutions.

Strengths:

Broad VFFS portfolio with modular machines suited to quick changeovers and multi-format runs.

Strong U.S. manufacturing footprint and parts/service network for fast support.

Active work on sustainability (machines that run recyclable/compostable films).

Specializations:

Continuous and intermittent VFFS (pillow, gusset, flat-bottom).

Pre-made pouch automation, stickpacks, and sachet systems.

Applications: frozen IQF, bakery, pet food, nutraceuticals, and other food products.

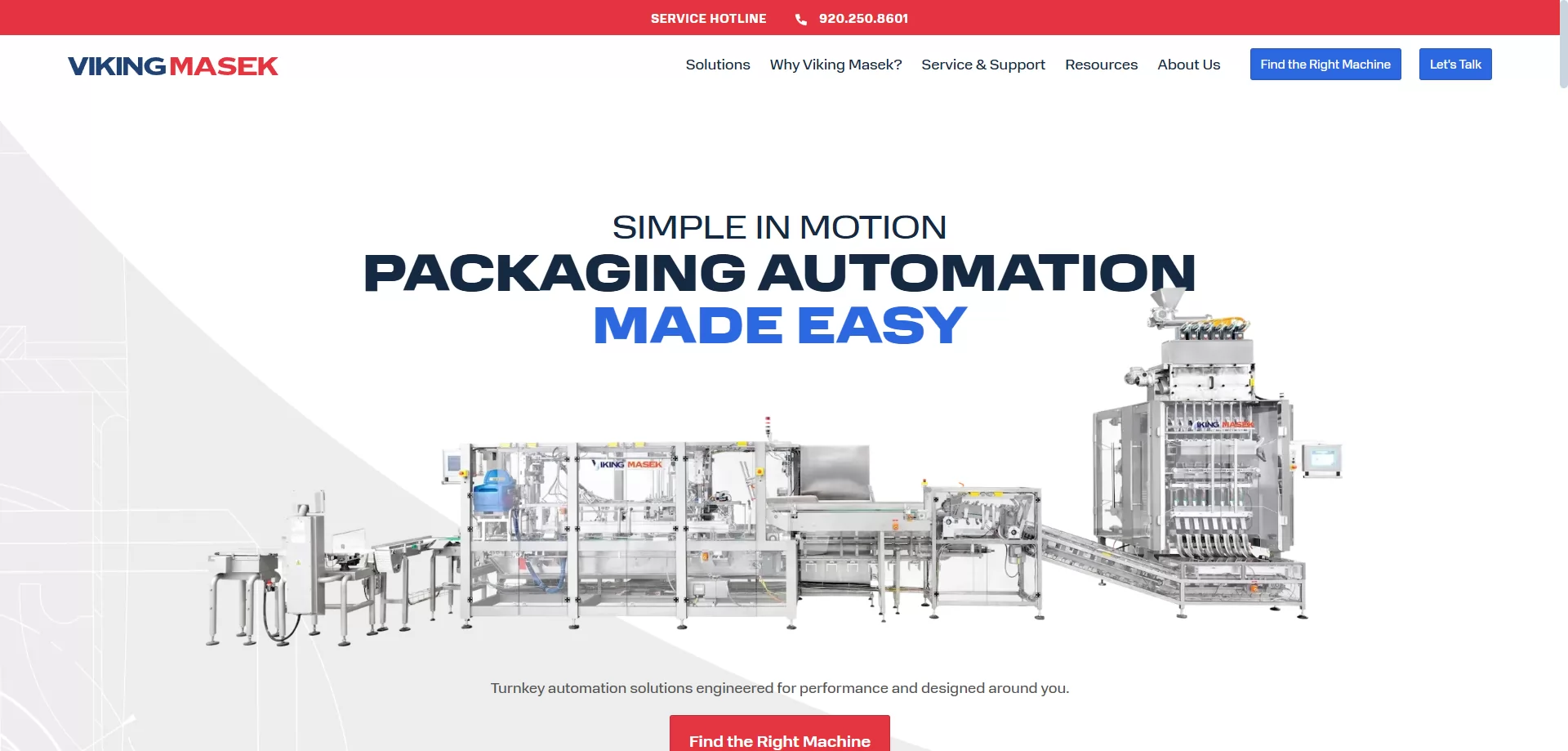

Overview:

Viking Masek provides turnkey packaging automation, including economical and high-speed VFFS baggers, premade-pouch fillers, flow wrappers, and end-of-line cartoning/case packing. Their approach emphasizes integrated systems—filling, inspection, cartoning and palletizing—positioning them as a full-line packaging partner.

Strengths:

Turnkey system design and integration (infeed → fill → inspection → palletizing).

Emphasis on user-friendly interfaces and service/parts support to reduce downtime.

Flexible product range that serves food, pharma/medical, and consumer goods.

Specializations:

VFFS machines (single- and multi-lane), flow wrappers, premade pouch systems.

End-of-line automation: cartoners, case packers, palletizing cells.

High-speed flow wrapping and stick/flow pack applications.

Overview:

Packline USA—now presenting itself as Packline Solutions Group—positions as a North American partner combining machinery, materials, and field service for food manufacturers. They focus on delivering integrated solutions across equipment and consumables to improve uptime and product quality.

Strengths:

Combined offering of equipment + packaging materials + local service (faster single-source support).

Deep food-industry focus with application engineering to match equipment to product.

Regional presence and supply chain for spare parts and consumables.

Specializations:

High-performance filling/sealing lines for cup, tray, and flexible packaging formats.

Integration projects for sauces, dips, dairy and other refrigerated products.

Consumables sourcing (films, lids) paired with machinery installs.

Overview:

Ossid (a ProMach brand) specializes in tray and flexible packaging machines—tray sealers, overwrappers, vacuum skin packaging (VSP) and horizontal form/thermoform fill-seal systems—commonly used in case-ready meat, seafood, produce and medical device packaging. Ossid’s portfolio is focused on leak-resistant tray sealing and robust end-of-line weighing/labeling.

Strengths:

Market focus on tray sealing and case-ready solutions with proven leak resistance.

Strong product breadth across thermoform, tray sealing, flow wrapping and weigh/price labeling.

Backed by ProMach, which provides systems integration and extended service resources.

Specializations:

Tray overwrapping and tray sealers for fresh and processed foods.

Horizontal thermoform fill-seal (HFFS) for medical devices and specialty products.

Weigh/price labeling and case-scale integration for retail distribution.

Overview:

Bartelt (also a ProMach brand) offers pouching (HFFS), cartoning, case/tray packing and shrink/overwrap systems. Their equipment targets flexible-pack and cartoning needs with an emphasis on robust, serviceable machines for medium- to high-volume production.

Strengths:

Diverse equipment lineup for pouching and horizontal form-fill-seal applications.

Focus on serviceability and operator ergonomics to keep lines running with lower total cost of ownership.

Active presence at industry trade shows and a track record of product updates.

Specializations:

HFFS pouchers, premade pouch systems, cartoners, and tray/case packing.

Industries: frozen foods, confectionery, pharmaceuticals, and consumer packaged goods.

Overview:

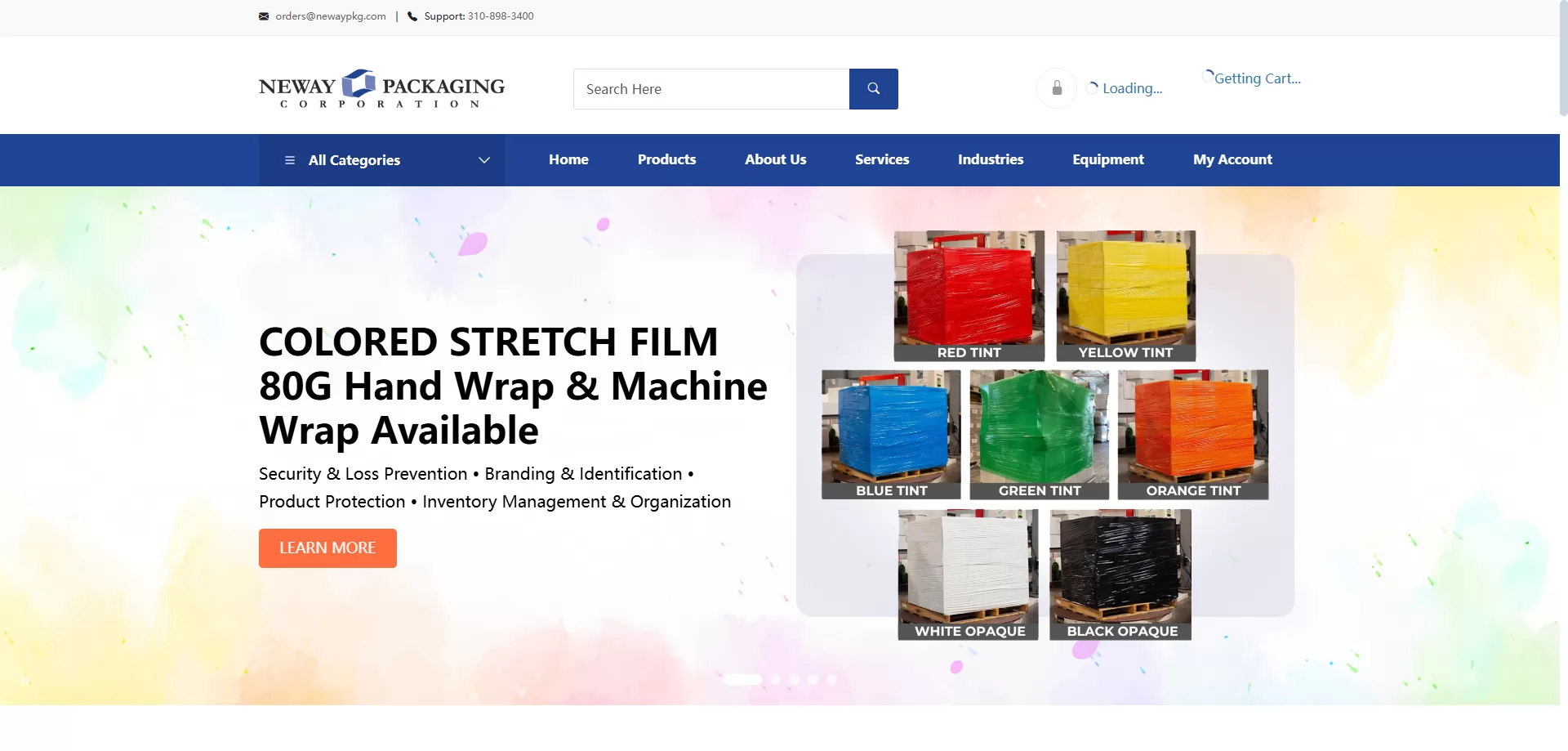

Neway Packaging is a U.S. distributor and service provider offering packaging materials, custom boxes, equipment installation, preventive maintenance and design services. Neway combines material supply with equipment services to support manufacturers that need both packaging and line-level support.

Strengths:

One-stop supplier model: materials, custom packaging, and equipment/service.

Field service and installation expertise—factory-trained technicians to preserve equipment warranties.

Localized support and ability to serve both small businesses and larger manufacturers.

Specializations:

Custom box design, packaging consumables, stretch/pallet wrap solutions.

Equipment installation, relocation, repair, and preventive maintenance across North America.

Overview:

Kyana Packaging Solutions is a family-owned packaging distributor and integrator that provides packaging materials, automation solutions, and industrial/ facility supplies. The company emphasizes productivity improvements via automation consulting and equipment selection.

Strengths:

Longstanding distributor with deep product inventory and hands-on consulting (iPAR® process).

Strong regional service, multi-vendor sourcing, and tools for cost-management (consulting software).

Emphasis on workforce and DEIB programs—useful for larger rollouts that require consistent supplier relationships.

Specializations:

Strapping, stretch wrap, corrugate, adhesives, and medium-level automation for packaging lines.

Solutions for manufacturing, distribution, and facility supply chains.

Overview:

Practical Packaging Solutions is a U.S.-based packaging machinery and supplies distributor and systems integrator that offers packaging materials, corrugated solutions, contract packaging and line automation for a wide range of customers. They combine distribution with engineering services for turnkey installs.

Strengths:

Broad distribution network and experience (decades of combined expertise) across machinery and supplies.

Contract packaging and packaging-engineering services that help customers outsource complex runs.

Emphasis on customized corrugated and protective packaging solutions.

Specializations:

Packaging line automation and integration, corrugated boxes, contract packaging services, and shrink/overwrap systems.

Serving food, industrial, and consumer goods firms that need both materials and integrated machinery.

Overview:

APEX Packaging Corporation is a long-standing U.S. distributor of packaging equipment and materials and also manufactures custom foam cushions and cold-chain insulated shipping containers. APEX supports package design and testing for food, pharmaceutical and medical shipments.

Strengths:

Broad equipment catalog (shrink tunnels, side sealers, conveyor systems) and a large online catalog for quick quoting.

Custom protective packaging capabilities (foam cushions, insulated shipping) that support cold-chain logistics.

Decades of experience in distribution plus contract packaging and validation services.

Specializations:

Case/tray/carton erectors, inline conveyors, shrink and sealing systems, and cold-chain container solutions.

Services: package design, testing/validation, and custom cushioning for fragile or temperature-sensitive products.

The top Filling and Sealing Machine Factories in the US 2025 demonstrate how American engineering excellence continues to set global benchmarks in precision, hygiene, and automation. Each of these factories offers unique strengths—from advanced form-fill-seal technologies to customizable inline systems—helping manufacturers improve productivity and maintain consistent packaging quality.

As industries move toward intelligent and eco-efficient production, partnering with a reliable Filling and Sealing Machine Factory becomes a strategic advantage. A factory that provides local technical support, fast spare-parts service, and continuous innovation can make a decisive difference in long-term operational success.

If your company is seeking a trusted partner to deliver high-performance filling and sealing machines, Yijianuo Machinery stands out as an ideal choice. With years of manufacturing expertise, a strong commitment to automation quality, and comprehensive after-sales service, Yijianuo Machinery provides complete solutions that integrate filling, sealing, and packaging into one efficient line.

Contact Yijianuo Machinery today to explore customized solutions tailored to your production requirements and take your packaging efficiency to the next level.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.