The U.S. food industry continues to evolve rapidly, driven by rising demand for ready-to-eat meals, stricter food safety regulations, and increasing pressure to improve production efficiency.

As a result, food manufacturers are placing greater emphasis on selecting reliable, compliant, and scalable food packaging machine suppliers.

Choosing the right food packaging machine manufacturer is no longer just about equipment price. It directly impacts:

Production efficiency and labor costs

Food safety and regulatory compliance

Packaging consistency and shelf life

Long-term maintenance and operational stability

This article presents a carefully researched list of the Top 10 Food Packaging Machine Manufacturers in the USA for 2026, focusing on companies that serve the U.S. market with proven technologies, industry-specific solutions, and long-term support capabilities.

This guide is designed for:

Food processing factories and manufacturers

Co-packers and contract packaging companies

Brands planning to expand or automate production lines

Procurement managers and technical decision-makers

Market focus: United States

Industry focus: Food and beverage packaging

Machine scope: Filling, sealing, thermoforming, vacuum, and integrated packaging lines

Time frame: 2026 industry outlook

To ensure this ranking delivers practical and trustworthy information, we applied a transparent and objective evaluation process. The goal is not to declare a single “best” manufacturer, but to help readers identify the most suitable suppliers for different production needs.

Manufacturers were reviewed based on the following key criteria:

Product capability and specialization

Industry application coverage

Technology level and automation capability

Market presence and service availability in the U.S.

Documented use cases and customer adoption

No single factor alone determines ranking position. Instead, manufacturers are evaluated holistically.

To reflect real-world production requirements, we focused on manufacturers offering one or more of the following food packaging equipment categories:

Liquid filling

Paste and viscous product filling

Granular and solid product filling

Tray sealing machines

Cup and bowl sealing machines

Heat sealing and ultrasonic sealing systems

Rigid and flexible film thermoforming

Integrated filling and sealing

High-output continuous systems

Vacuum packaging machines

Modified Atmosphere Packaging (MAP)

Shelf-life extension solutions for meat and ready meals

Manufacturers were assessed based on their ability to serve diverse food sectors, including:

Ready meals and prepared foods

Meat, poultry, and seafood

Dairy products and beverages

Frozen foods

Pet food and specialty food products

Companies with clear application focus and proven installations scored higher than those with overly broad or unclear positioning.

The information used in this ranking is based on:

Official manufacturer websites and product catalogs

Publicly available technical documentation

Industry publications and trade references

Case studies and application descriptions released by manufacturers

No proprietary or unverifiable claims are used. Where limitations exist, they are stated clearly.

This list reflects general market positioning and publicly available information as of 2026.

Actual suitability may vary depending on:

Specific product characteristics

Local service availability

Customization requirements

Budget and delivery timelines

Readers are encouraged to use this ranking as a shortlisting tool, not a final purchasing decision.

_1769482950_WNo_1600d900.webp)

BW Packaging, a leading food packaging machine manufacturer, is part of Barry-Wehmiller, a $3.5 billion global supplier of manufacturing equipment established in 1885. As a prominent food packaging machine manufacturer, BW Packaging specializes in comprehensive packaging machinery and solutions, encompassing flexible systems, rigid systems, labeling, end-of-line solutions, and full packaging line integration. Serving markets including food, beverage, personal care, and pharmaceuticals, this food packaging machine manufacturer operates with over 40 locations worldwide and more than 2,000 team members. Emphasizing a customer-centric approach, BW Packaging addresses challenges in food packaging equipment by optimizing processes, providing lifetime support, and focusing on key initiatives like sustainability through energy-efficient designs, responsible materials, and transparent reporting; integration via end-to-end lines; automation for enhanced efficiency; and performance to maximize overall equipment effectiveness (OEE) in food packaging machinery. Their global footprint ensures tailored food packaging solutions that drive business growth and operational reliability.

As a certified food packaging machine manufacturer, BW Packaging maintains professional qualifications through compliance with standards such as 3-A for hygienic design, CE marking, and FDA regulations in food packaging equipment. Their achievements include being a finalist in the 2022 Sustainability Awards for Snapcut technology, which advances eco-friendly food packaging solutions, and recognition from PMMI for emerging leaders in packaging innovation. In 2025, BW Packaging integrated its divisions—BW Filling & Closing, BW Flexible Systems, and BW Integrated Systems—into a unified organization, enhancing collaboration and enabling faster innovation in food packaging machinery. This food packaging machine manufacturer has earned acclaim for delivering reliable, high-performance food packaging equipment that improves OEE, reduces environmental impact, and supports sustainable practices like downgauging shrink films and all-electric palletizers. With a portfolio of trusted brands like Pneumatic Scale Angelus and Accraply, BW Packaging stands out for its expertise in hygienic, efficient food packaging solutions, fostering long-term customer trust and industry leadership.

Drawing from over 40 years of expertise as a food packaging machine manufacturer, BW Packaging has executed diverse projects in food packaging equipment across segments like dairy, frozen foods, and confectionery. A notable case involved optimizing product mix accuracy for a pet food company, where advanced food packaging machinery ensured precise inclusion of freeze-dried components in 10-20 lb. bags, boosting efficiency. Another example is collaborating with a multinational confectionary manufacturer to convert vertical form-fill-seal (VFFS) baggers for paper materials, resulting in sustainable, visually appealing lozenge packaging. For the Killer Brownie Company, BW Packaging provided a horizontal flow wrapper (HFFS) solution, enabling flexible brownie packaging with minimal training and expanded sales channels. In dairy applications, they deployed yogurt cup form-fill-seal lines for seamless production, while frozen food clients benefited from IQF packaging lines that enhanced hygiene and throughput. This food packaging machine manufacturer's proven track record in integrating food packaging solutions demonstrates consistent improvements in productivity, waste reduction, and compliance for global clients.

BW Packaging's team of over 2,000 global packaging professionals, led by President Rachana Creeth, embodies a people-centric culture focused on care, trust, and development, as highlighted in initiatives like the ShePacks series profiling inspirational women such as Chief Product Officer Denning Saum and Vice President Daniela Israel. As a forward-thinking food packaging machine manufacturer, they prioritize innovation in food packaging equipment, including smart human-machine interfaces (HMIs) for simplified operator training, collaborative robots (cobots) for safe automation, and sustainable technologies like recyclable shrink sleeve labels and fiber bowl systems for frozen foods. Recent advancements feature the all-electric Maximus case palletizer and open-source HMIs to lower costs in food packaging machinery. Their commitment extends to four core areas: sustainability through eco-efficient designs, integration for seamless lines, automation to address labor challenges, and performance enhancements for optimal OEE. This collaborative approach ensures agile, innovative food packaging solutions that solve complex industry needs and support lifetime customer partnerships.

Vertical and horizontal form-fill-seal (VFFS / HFFS) machines

Filling and dosing systems

Case packing and end-of-line automation

Integrated packaging lines for food products

Strong engineering capabilities for large-scale production

Broad portfolio covering primary and secondary packaging

Established U.S.-based service and support network

Suitable for continuous, high-speed manufacturing environments

Higher investment cost compared to entry-level suppliers

Less flexible for small batch or highly customized niche products

Longer lead times for complex system integration

Snack foods

Bakery products

Frozen foods

Packaged consumer foods

Large food manufacturers and multinational brands seeking robust, high-output packaging systems with long-term service support in the U.S.

Syntegon, a leading Food Packaging Machine Manufacturer, specializes in advanced packaging solutions and processing equipment for the food, pharmaceutical, and biotech industries. Headquartered in Waiblingen, Germany, the company was founded in 1969 as Robert Bosch Apparatebau GmbH and rebranded as Syntegon in 2020 after becoming independent from the Bosch Group, drawing on over 160 years of engineering heritage. With approximately 6,300 employees worldwide, Syntegon delivers seamless processes, high-speed packaging systems, and sustainable food processing equipment to enhance efficiency, product quality, and environmental responsibility. As a strategic lifecycle partner, this Food Packaging Machine Manufacturer focuses on mission-critical technologies like vertical form-fill-seal machines, horizontal flow wrappers, and bioprocess systems, ensuring compliance with global standards while minimizing risks in food packaging production. Syntegon's expertise in food packaging solutions includes innovative handling for snacks, confectionery, and baked goods, supporting manufacturers in achieving higher throughput and reduced material waste through eco-friendly packaging alternatives. The company's global presence spans multiple locations, enabling tailored food processing equipment and packaging solutions that drive competitive advantages in dynamic markets.

Syntegon, renowned as a Food Packaging Machine Manufacturer, holds extensive qualifications in engineering excellence, backed by over 2,000 patents and compliance with stringent regulations like EU GMP Annex 1 for food and pharma packaging solutions. Its achievements include record financial results in 2024, with strong growth in food business driven by high-performance horizontal packaging divisions in Switzerland, and stable development in 2022 amid market challenges. As a top Food Packaging Machine Manufacturer, Syntegon has earned prestigious awards such as the BME Innovation Award 2021 for purchasing transformation, Baden-Württemberg Design Award FOCUS Silver 2025 for its RMA assembly solution, and PDA Drug Delivery Innovation Award 2021 for Versynta microBatch technology. Further accolades include the German Packaging Award, Red Dot Award, PMMI Packaging Line of the Year, and Kununu Top Company 2026 for workplace excellence. In sustainability, this Food Packaging Machine Manufacturer achieved significant progress in 2024, targeting net-zero emissions by 2040, and pioneered eco-friendly food processing equipment like paper-based wrappers for confectionery. These qualifications underscore Syntegon's leadership in delivering reliable, innovative packaging solutions and food processing equipment worldwide.

With over 50 years in specialized sites like Denmark and Germany, Syntegon, a prominent Food Packaging Machine Manufacturer, boasts extensive experience in deploying thousands of machines globally for food packaging solutions and processing equipment. Its portfolio includes installations for major clients, enhancing production efficiency through high-speed systems. Key case studies highlight this expertise: Snack Connection upgraded to Syntegon's Elematic 2001 WA case packer, boosting packaging speeds to 40 cases per minute for nuts and snacks, improving overall food packaging efficiency. Nature's Path, an organic food producer, implemented Syntegon's Kliklok ACE case packer, reducing cardboard use by 50% and increasing output for cereal boxes, aligning with sustainability goals in food processing equipment. Family-owned Leclerc installed two state-of-the-art bar packaging systems at its Canadian and U.S. sites, enabling high-volume production of granola bars with flexible, sustainable packaging solutions. Mars Wrigley partnered for eco-friendly transitions, swapping plastic for paper wraps on Balisto bars using Syntegon's food packaging machines, maintaining quality while reducing environmental impact. Almarai, a bakery leader, utilized customized flow wrappers for efficient biscuit packaging. These examples demonstrate Syntegon's proven track record as a Food Packaging Machine Manufacturer in delivering tailored, reliable solutions across diverse food sectors.

Syntegon's team of around 6,300 experts, recognized as a Kununu Top Company 2026, drives innovation in food packaging solutions and processing equipment through collaborative engineering and customer co-creation. This Food Packaging Machine Manufacturer fosters a culture of excellence, earning awards like the Børsen Gazelle for growth and the Equipment Innovation Award for Makat NutraFlash technology. Internal accolades, such as the Syntegon Awards 2023 for the Tablet Press APD Team's feeder innovation, highlight team-driven advancements. Innovations include the SynTiso line for high-speed filling, achieving 600 containers per minute with gloveless isolators, and sustainable VFFS machines for eco-friendly food packaging. The FGCT count feeder for cookies, premiered at iba 2025, exemplifies precision in snack handling. Syntegon's R&D, backed by 2,000 patents, focuses on user-oriented designs like the RMA for assembly, earning the Baden-Württemberg Design Award. As a Food Packaging Machine Manufacturer, the team pioneers sustainable innovations, such as paper-based systems, ensuring future-proof food processing equipment and lifecycle services that accelerate market leadership.

Syntegon is a global technology company specializing in processing and packaging solutions for food and pharmaceutical industries. Although headquartered in Europe, Syntegon maintains a significant operational footprint in the United States, serving major food producers across multiple sectors.

The company is known for precision engineering, automation, and compliance-driven design.

Thermoforming packaging machines

Flow wrapping systems

Vacuum and MAP packaging machines

Integrated filling and sealing systems

Advanced automation and digital monitoring capabilities

Strong focus on food safety and hygienic design

Excellent performance in thermoforming and vacuum packaging

Suitable for regulated and high-value food products

High capital investment

More complex system operation requiring trained staff

Not ideal for very small or low-budget operations

Meat and poultry

Cheese and dairy products

Ready meals

High-end packaged foods

Medium to large food processors requiring high-precision, compliance-oriented packaging solutions and advanced automation.

HonorPack is a packaging machinery manufacturer specializing in flexible packaging equipment. While not U.S.-headquartered, the company actively serves the U.S. market and is known for offering competitively priced solutions for form-fill-seal and pouch packaging applications.

HonorPack focuses on balancing automation with cost efficiency.

Vertical form-fill-seal (VFFS) machines

Premade pouch packaging machines

Multi-head weigher integration

Filling systems for granular and solid foods

Cost-effective solutions for flexible packaging

Wide compatibility with weighing and dosing systems

Faster delivery compared to large system integrators

Suitable for startups and growing brands

Limited focus on rigid packaging (tray, cup, bowl)

Smaller U.S. service footprint compared to domestic manufacturers

Less suited for highly regulated food environments

Snacks and nuts

Coffee and dry foods

Frozen foods

Powder and granular products

Small to mid-sized food companies seeking flexible packaging automation at a controlled budget.

Company Overview

Rocket Machine Works Inc., a leading Food Packaging Machine Manufacturer based in Fresno, California, USA, has been specializing in custom-engineered filling and sealing equipment for over 30 years. As a dedicated Food Packaging Machine Manufacturer, the company designs and builds rotary filling machines, inline sealing machines, and tray sealing machines tailored for food industry applications, handling containers like cups, trays, clamshells, jars, and bottles. Their equipment supports hot or cold products, ensuring sanitary design compliant with FDA, NSF, and USDA standards through all-stainless steel construction and direct washdown capabilities. Focused on affordability and reliability, this Food Packaging Machine Manufacturer offers expandable systems for seamless integration, from standalone piston fillers to high-volume rotary fillers achieving up to 90 containers per minute. With a commitment to U.S.-made quality, Rocket Machine Works serves diverse food sectors, including dairy, snacks, and prepared meals, emphasizing precision in filling machines and sealing machines to enhance product freshness and shelf life.

As a certified Food Packaging Machine Manufacturer, Rocket Machine Works holds qualifications in engineering equipment to meet stringent FDA, NSF, and USDA standards, utilizing stainless steel for sanitary, washdown-ready designs in filling machines and sealing machines. Their achievements include developing rotary fillers and inline sealers that double production efficiency, as evidenced by client testimonials praising low maintenance and reliable operation in food packaging environments. The company has participated in major industry events like PACK EXPO Las Vegas, showcasing innovations in tray sealers and auxiliary equipment such as accumulation tables and conveyors. Recognized for over 28-30 years of expertise, this Food Packaging Machine Manufacturer has earned a loyal client base through competitive pricing, custom solutions, and features like no-container/no-fill logic and tamper-evident sealing, ensuring compliance and high-speed performance up to 300 containers per minute. Awards and qualifications underscore their focus on quality, with machines engineered for durability in multi-shift operations across the food industry.

With more than 30 years as a Food Packaging Machine Manufacturer, Rocket Machine Works boasts extensive experience in creating filling machines, sealing machines, and rotary fillers for food producers nationwide. Their portfolio includes custom projects for diverse applications, from yogurt and sauces to prepared meals and sustainable packaging, demonstrating versatility in inline sealers and tray sealers. Case studies highlight success: Bobby Salazar’s Mexican Foods Inc. reported doubled production and minimal downtime with their rotary filling machines, praising easy adjustments and reliability in high-volume food packaging. Delori Products commended innovative custom engineering in sealing machines for honest, effective solutions to packaging challenges. J&L Food Specialties noted competitive pricing and problem-solving in tray sealing equipment, enhancing operational efficiency. This Food Packaging Machine Manufacturer's experience extends to rebuilding and retrofitting, ensuring long-term value for clients in dairy, snacks, and condiment sectors.

The team at Rocket Machine Works, a premier Food Packaging Machine Manufacturer, consists of seasoned engineers and technicians with deep expertise in food packaging technology, focusing on custom designs for filling machines and sealing machines. Led by professionals like Mike vonHusen, they prioritize customer goals, attending trade shows to showcase rotary fillers and inline sealers. Innovations include PLC-controlled systems with remote access for quick diagnostics, reducing downtime in tray sealing machines and accumulation tables. As a forward-thinking Food Packaging Machine Manufacturer, they incorporate advanced features like registered print sealing, hopper agitators, and eco-friendly options for sustainable packaging, adapting to trends like high-barrier trays and microwave-safe containers. Their innovative approach ensures expandable, future-proof equipment, with warranties and ongoing support fostering long-term partnerships in the food industry.

Entry-level food packaging machines

Sealing equipment for foodservice use

Vacuum sealing solutions

Packaging accessories and consumables

Strong distribution and logistics network in the U.S.

Easy access to equipment for foodservice operators

Lower entry barrier for small operations

Reliable after-sales availability

Limited customization and automation depth

Not suitable for industrial-scale food manufacturing

Focused more on equipment supply than engineering solutions

Restaurants and catering services

Central kitchens

Institutional food operations

Small food preparation facilities

Foodservice operators and small-scale food businesses requiring basic, accessible packaging equipment rather than full production lines.

Accutek Packaging Equipment Companies, Inc. is a prominent Food Packaging Machine Manufacturer based in Vista, California, with additional facilities in Texas and Florida. Founded in 1989, this privately held company specializes in turnkey packaging solutions, including liquid filling machines, capping machines, and labeling machines tailored for the food industry and beyond. As a leading Food Packaging Machine Manufacturer, Accutek focuses on customizable equipment for handling various products, such as viscous liquids, foaming substances, and particulates commonly found in food packaging. With 36 years of operation, the company has produced over 78,000 machines, serving diverse sectors like food, beverages, cosmetics, and pharmaceuticals.

In terms of professional qualifications and achievements, Accutek holds a strong reputation as a Food Packaging Machine Manufacturer with a 4.7 customer rating from 96 reviews, emphasizing reliability, precision, and innovation. Achievements include long-lasting machinery (up to 20 years of service) and rapid custom deliveries, such as completing extensive projects in weeks. The company adheres to high standards in mechanical precision and control systems, making it a trusted Food Packaging Machine Manufacturer for efficient, waste-reducing solutions.

Accutek's experience spans decades, with case studies highlighting successful implementations in food packaging. For instance, clients in the food sector have utilized liquid filling machines for essential oils and alcohol-based products, achieving automation that frees up manual labor and ensures compliance. Other examples include customized capping and labeling for small-batch craft production in food and beverages, reducing downtime and boosting output.

The team at this Food Packaging Machine Manufacturer comprises skilled engineers, sales experts like Johnny Martinez, and support staff focused on perfectionism and customer training. Innovation drives Accutek, with advancements in touchscreen interfaces, high-speed rotary systems, and scalable designs for growing food packaging operations.

Liquid and paste filling machines

Capping and sealing machines

Labeling systems

Integrated filling and packaging lines

Strong U.S.-based manufacturing and support

Modular equipment design allows phased automation

Broad application coverage across food and beverage

Well-documented customer installations

Less focus on thermoforming packaging

Limited specialization in high-speed tray sealing systems

Advanced customization may increase lead time

Sauces and condiments

Beverages

Dairy products

Specialty food products

Food manufacturers seeking scalable, modular filling and packaging systems with strong U.S. service support.

Great Pack, a leading Food Packaging Machine Manufacturer based in Kunshan, Jiangsu, China, specializes in turnkey solutions for efficient and customizable packaging systems. Established in 2011 as Kunshan Great Automatic Machinery Co., Ltd., the company focuses on vertical form fill seal technology and related machinery to meet the demands of industries like food and beverage, healthcare, non-food products, and pet food. As a reliable Food Packaging Machine Manufacturer, Great Pack emphasizes precision production, high-quality materials, and full-service support to secure the final production step for clients worldwide.

In terms of professional qualifications and achievements, Great Pack utilizes CE-certified parts made from durable materials to minimize maintenance costs. Their machines incorporate high-precision servo-controlled film-tension systems, color sensors, and advanced technology sourced from Japan for fast and accurate bagging. The company maintains stable lead times of 45-60 days and provides assured after-sales services, including technical training and 24-hour response to client concerns. Recognized for custom designs that enhance productivity, Great Pack has earned trust through its commitment to quality and efficiency in the packaging sector.

With over 15 years of experience since its founding, Great Pack has delivered custom packaging solutions across multiple industries, increasing bagging output and meeting tight deadlines. Notable cases include tailored machines for sanitary food packaging in the food and beverage sector, precise medicinal goods handling in healthcare, and protective packaging for pet treats. These projects demonstrate the company's ability to handle diverse materials at high speeds while ensuring accuracy and protection.

The team at Great Pack consists of experienced professionals who offer specialized packaging solutions and services. Innovation is driven by client insights, leading to modular customizations that improve efficiency and reduce costs. By integrating latest technologies, the company continues to advance in the Food Packaging Machine Manufacturer space.

Great Pack is a packaging machinery supplier focusing on flexible packaging and form-fill-seal equipment. The company serves food manufacturers requiring efficient pouch and bag packaging solutions, particularly in cost-sensitive production environments.

Vertical form-fill-seal (VFFS) machines

Pouch packaging systems

Weighing and dosing integration

Competitive pricing for flexible packaging solutions

Simple machine structure with easier operation

Suitable for standardized packaging formats

Limited application in rigid packaging formats

Less suitable for complex automation lines

Smaller U.S. service footprint

Snacks

Frozen foods

Dry and granular products

Small to mid-sized food processors prioritizing cost efficiency in flexible packaging.

Viking Masek Packaging Technologies, a leading Food Packaging Machine Manufacturer, specializes in automated food packaging machinery and turnkey solutions for the food and beverage industry. Founded in 2002 as Leonhard Packaging Solutions in Wisconsin, USA, by brothers Rick and Robb Leonhard, the company evolved through a strategic partnership with Czech-based Masek in 2006, combining over 60 years of expertise in packaging automation. Headquartered in Oostburg, WI, with production facilities in the Czech Republic and USA, Viking Masek serves global markets in more than 80 countries, manufacturing over 220 machines annually for applications like coffee, pet food, confectionery, and frozen goods.

As a premier Food Packaging Machine Manufacturer, Viking Masek holds accolades including Sheboygan County Manufacturer of the Year and multiple Top Workplaces honors from the Milwaukee Journal Sentinel. The company has invested in sustainable innovations, such as a rooftop solar array at its US headquarters, and expanded facilities with a $4 million project in 2020 to double production capacity. Achievements include pioneering the STANDCAP pouch launch and strategic partnerships, like with IAS Inc. for enhanced automation, solidifying its reputation in reliable, high-speed food packaging systems.

With decades of experience as a Food Packaging Machine Manufacturer, Viking Masek has delivered solutions to diverse clients. For Big Easy Blends, automated premade pouch machines resolved quality issues in beverage packaging, boosting efficiency. Just Us Coffee improved coffee product sealing and output with vertical form fill seal machines. Fairview Mills transitioned from manual to automated systems for pet food, enhancing morale and speed. Death Wish Coffee scaled production with VFFS M400 baggers, meeting rapid demand growth in the coffee sector.

Viking Masek's team of over 300 professionals, led by CEO Matt Miller, President Bryan Lacy, and CFO Nicole Piontek, emphasizes collaboration and customer-focused innovation. Regional sales experts drive advancements in food packaging technologies, including dust-control powder solutions and flow wrappers for minimal downtime. Innovations like robotic integration and scalable turnkey lines ensure precision in food packaging machine manufacturing, supported by ongoing training and maintenance services.

Tray sealing machines

Vacuum packaging systems

Shrink wrapping machines

MAP packaging solutions

Strong specialization in tray sealing and vacuum packaging

Reliable equipment for foodservice and retail use

Established U.S. sales and service network

Less focus on fully automated production lines

Limited filling system integration

Not designed for ultra-high-speed industrial output

Meat and poultry

Ready meals

Retail food packaging

Foodservice operations

Foodservice operators and mid-scale processors requiring reliable tray sealing and vacuum packaging equipment.

Viking Masek Packaging Technologies, a leading Food Packaging Machine Manufacturer, specializes in automated food packaging machinery and turnkey solutions for the food and beverage industry. Founded in 2002 as Leonhard Packaging Solutions in Wisconsin, USA, by brothers Rick and Robb Leonhard, the company evolved through a strategic partnership with Czech-based Masek in 2006, combining over 60 years of expertise in packaging automation. Headquartered in Oostburg, WI, with production facilities in the Czech Republic and USA, Viking Masek serves global markets in more than 80 countries, manufacturing over 220 machines annually for applications like coffee, pet food, confectionery, and frozen goods.

As a premier Food Packaging Machine Manufacturer, Viking Masek holds accolades including Sheboygan County Manufacturer of the Year and multiple Top Workplaces honors from the Milwaukee Journal Sentinel. The company has invested in sustainable innovations, such as a rooftop solar array at its US headquarters, and expanded facilities with a $4 million project in 2020 to double production capacity. Achievements include pioneering the STANDCAP pouch launch and strategic partnerships, like with IAS Inc. for enhanced automation, solidifying its reputation in reliable, high-speed food packaging systems.

With decades of experience as a Food Packaging Machine Manufacturer, Viking Masek has delivered solutions to diverse clients. For Big Easy Blends, automated premade pouch machines resolved quality issues in beverage packaging, boosting efficiency. Just Us Coffee improved coffee product sealing and output with vertical form fill seal machines. Fairview Mills transitioned from manual to automated systems for pet food, enhancing morale and speed. Death Wish Coffee scaled production with VFFS M400 baggers, meeting rapid demand growth in the coffee sector.

Viking Masek's team of over 300 professionals, led by CEO Matt Miller, President Bryan Lacy, and CFO Nicole Piontek, emphasizes collaboration and customer-focused innovation. Regional sales experts drive advancements in food packaging technologies, including dust-control powder solutions and flow wrappers for minimal downtime. Innovations like robotic integration and scalable turnkey lines ensure precision in food packaging machine manufacturing, supported by ongoing training and maintenance services.

Vertical form-fill-seal machines

Bagging systems

Integrated weighing and dosing solutions

Efficient automation for standardized packaging

Compact machine footprint

Suitable for continuous production

Limited support for rigid packaging formats

Less customization for complex food products

Not ideal for high-mix production

Snacks

Dry food products

Frozen foods

Manufacturers seeking stable, automated flexible packaging systems for standardized products.

Black Forest Packaging Solutions, LLC, established in 2010 as a leading Food Packaging Machine Manufacturer, specializes in innovative flexible packaging equipment for the food industry. Headquartered in Norcross, Georgia, USA, this Food Packaging Machine Manufacturer partners with Wolf Verpackungsmaschinen GmbH to deliver high-quality vertical form fill seal machines and related systems. As a prominent Food Packaging Machine Manufacturer, it focuses on solutions for liquids, viscous products, solids, powders, and granules, serving sectors like food and beverage with reliable packaging machinery that ensures efficiency and product integrity.

As a certified Food Packaging Machine Manufacturer, Black Forest holds expertise in manufacturing and distributing vertical form fill seal machinery, auger fillers, and cup fillers. Achievements include over 25 years of combined experience through its Wolf Packaging Machines USA subsidiary, establishing it as a reputable Food Packaging Machine Manufacturer with superior accuracies and sustainable production speeds in liquid filling operations. The company is recognized for its stainless steel washdown designs and continuous-motion operations, earning consistent client orders and long-term relationships.

With extensive experience as a Food Packaging Machine Manufacturer, Black Forest has served wholesalers, distributors, grocery stores, and dairy farms, packaging products like soups, sauces, condiments, salad dressings, snack foods, IQF items, and pet food. Case examples include multi-component fills for raw marinated chicken, taco meat, and macaroni & cheese, demonstrating versatile applications across frozen to hot temperatures (up to 195°F+). Its track record as a Food Packaging Machine

Black Forest Packaging provides packaging machinery and solutions primarily for small to mid-sized food producers. The company focuses on accessible equipment that bridges the gap between manual packaging and full automation.

Entry-level packaging machines

Sealing and wrapping equipment

Semi-automatic systems

Lower entry cost

Easy operation and maintenance

Practical solutions for growing businesses

Limited scalability for large production volumes

Fewer options for advanced automation

Narrower product range

Artisan food producers

Small batch food manufacturing

Specialty and local food brands

Small food businesses transitioning from manual to semi-automated packaging.

Yijianuo Machinery, a prominent Food Packaging Machine Manufacturer based in Wuhan, Hubei Province, China, specializes in advanced automatic packaging solutions for the food, beverage, pharmaceutical, and consumer goods industries. Established in 2012, the company operates from a production base exceeding 10,000 square meters and focuses on integrating research, development, design, production, and sales of Food Packaging Machines, including filling and sealing systems, thermoforming packing machines, and spout pouch equipment. As a high-tech enterprise, Yijianuo Machinery emphasizes quality, innovation, and service, providing one-stop solutions for efficient, intelligent Food Packaging Machine systems that enhance production lines worldwide.

Yijianuo Machinery holds ISO 9001 certification, underscoring its commitment to quality management in Food Packaging Machine manufacturing. Recognized as a high-tech enterprise, it has achieved global acclaim for superior Food Packaging Machine quality and service over the years, including participation in international exhibitions like the Southeast Asia Food & Beverage Processing Exhibition in 2024, where it showcased vacuum tray packaging and spout pouch filling lines for dairy, sauces, and meats. The company has also developed innovative solutions such as an ice hockey puck packaging line in 2025, meeting export standards and supporting customized Food Packaging Machine applications.

With over 20 years of collective manufacturing experience in Food Packaging Machines, Yijianuo Machinery serves diverse sectors including dairy, ready meals, frozen products, pet food, and snacks. Notable cases include a Pasta Cup Packaging Line for a Polish listed company, a Turnkey Natto Production Line in 2024, Dessert Packaging Machines for GMS PRO in Belarus, and a High-Speed Honey Jam Packaging Line, demonstrating reliable Food Packaging Machine performance in real-world applications.

Yijianuo Machinery boasts a dedicated team of over 160 employees, including a strong R&D group focused on innovating Food Packaging Machine technologies for efficiency and reduced energy use. Innovation drives features like precise filling, clean sealing, and integration with freezing systems, positioning the company as a leader in smart Food Packaging Machine solutions with customizable designs and long-term technical support.

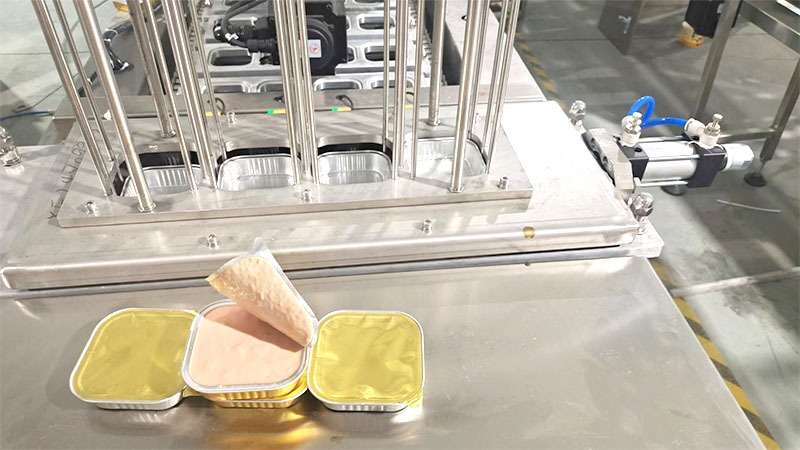

Cup, tray, bowl, and box filling & sealing machines

Thermoforming vacuum packaging machines

Spout pouch filling and capping machines

Integrated automatic food packaging production lines

Strong specialization in filling and sealing applications

Ability to customize molds and machine configurations based on container size and product type

Experience with complete automatic production lines

Suitable for high-viscosity, liquid, and solid food products

Not a U.S.-headquartered manufacturer

U.S. service support may rely on project-based arrangements

Longer lead time for highly customized systems

Ready meals and prepared foods

Beverage cups and bowl-packed foods

Meat and protein products (tray packaging, vacuum packaging)

Pet food and specialty food packaging

Food manufacturers seeking customized filling and sealing solutions, especially for cup, tray, bowl, and box packaging formats, and willing to work with an international supplier serving the U.S. market.

Selecting a food packaging machine manufacturer requires more than comparing machine prices. The right supplier should align with your product characteristics, production goals, compliance requirements, and long-term growth plans.

The following considerations help buyers make informed, risk-aware decisions.

Different food products place very different demands on packaging equipment. Before evaluating suppliers, clearly define:

Liquid, semi-liquid, paste, granular, or solid

Viscosity and flow behavior

Presence of particulates or inclusions

Machines designed for thin liquids often perform poorly with viscous or chunky products, and vice versa.

Hot-fill or cold-fill processes

Frozen or refrigerated products

Sensitivity to oxygen or moisture

These factors directly influence filling accuracy, sealing method, and material compatibility.

Packaging format determines both machine structure and future scalability.

Cups, bowls, trays, boxes

Often require filling + sealing integration

Common in ready meals, dairy, and protein packaging

Bags, pouches, spout pouches

Typically use form-fill-seal or premade pouch machines

Common for snacks, dry foods, and liquids

Choosing a manufacturer with proven experience in your exact packaging format reduces commissioning risk.

Automation needs vary significantly by operation size and labor availability.

Lower investment cost

Higher labor involvement

Suitable for small batches or pilot production

Higher throughput and consistency

Reduced labor dependency

Higher initial investment but lower long-term cost per unit

Manufacturers that offer modular or scalable systems allow gradual automation as demand grows.

Food packaging equipment must comply with relevant regulations and safety standards.

Key considerations include:

FDA and USDA compatibility

Hygienic machine design (easy cleaning, food-grade materials)

Electrical and safety certifications where applicable

Manufacturers with documented experience serving regulated food industries typically provide better long-term reliability.

Machine performance over time depends heavily on service and technical support.

Evaluate:

Availability of spare parts

Remote troubleshooting capabilities

On-site installation and training options

Response time for technical issues

A technically strong machine without reliable support can become a production bottleneck.

Both domestic and international suppliers serve the U.S. food packaging market.

Faster service response

Easier communication

Often higher cost

Broader customization options

Competitive pricing

Longer lead times and project-based service

The best choice depends on risk tolerance, budget, and technical complexity.

This section addresses practical questions buyers frequently face during procurement.

While prices vary widely, general ranges include:

Entry-level machines: lower investment, limited automation

Mid-range systems: balance of automation and flexibility

Integrated production lines: higher upfront cost, long-term efficiency

Customization, materials, and automation level significantly influence final pricing.

Typical project timelines include:

Equipment manufacturing and testing

Shipment and on-site installation

Operator training and commissioning

Highly customized systems require longer preparation but often deliver better production alignment.

Standard machines offer:

Faster delivery

Lower upfront cost

Customized machines offer:

Better fit for specific products

Improved efficiency and reduced waste

Manufacturers with strong engineering capability can balance both approaches.

Common machines include filling machines, tray sealing machines, thermoforming packaging systems, vacuum packaging machines, and form-fill-seal machines, depending on product type and packaging format.

Costs vary widely based on automation level, materials, and customization. Entry-level machines cost significantly less than fully automated production lines designed for high-volume manufacturing.

Reliability depends on engineering quality, application experience, and support structure—not location alone. Many international manufacturers successfully serve the U.S. market through project-based service and partnerships.

Machines should be compatible with FDA and USDA food safety requirements. Electrical and safety certifications may also be required depending on installation location and application.

With proper maintenance, food packaging machines can operate reliably for many years. Long-term performance depends on build quality, service support, and operating conditions.

Some machines offer flexibility for multiple products, but frequent changeovers may reduce efficiency. Machines designed for specific product types typically perform better.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.