As global demand for reliable and efficient packaging continues to rise, the role of Packaging Sealing Machine Manufacturers in the United States has become more essential than ever. In 2025, industries such as food and beverage, pharmaceuticals, consumer goods, and e-commerce fulfillment rely heavily on automated sealing technologies to protect product integrity, extend shelf life, and improve production efficiency.

The U.S. remains a powerhouse in packaging machinery innovation, with manufacturers integrating advanced automation, energy-efficient technology, and safety-driven engineering into their sealing systems. This article explores the Top 10 Packaging Sealing Machine Manufacturers in the USA (2025)—but before diving into individual companies, it’s important to understand how these leaders were selected, the trends shaping the industry, and the key factors buyers must consider when choosing sealing machinery.

Selecting the top U.S. sealing machine manufacturers requires a measured and objective approach. The following criteria were used to determine inclusion in the 2025 ranking:

1. Market Presence & Industry Reputation

Companies were evaluated based on their market longevity, industry influence, and customer trust. Long-term performance and innovation leadership played an important role.

2. Product Range & Specialization

From carton sealers and heat sealers to vacuum sealing systems and pouch sealing machines, manufacturers offering broad, flexible, or highly specialized product lines received higher visibility.

3. Technology, Automation, and Innovation

2025 packaging operations demand machines that integrate robotics, predictive maintenance, IoT connectivity, and next-generation safety features.

4. Compliance, Certifications & Quality Standards

Manufacturers aligned with FDA, GMP, USDA, and other U.S. industry standards scored higher for reliability and customer confidence.

5. Service, Support & Total Cost of Ownership

Manufacturers offering strong after-sales support, easy access to spare parts, and high machine uptime were prioritized.

This methodology ensures a clear, credible, and data-driven ranking of the top U.S. Packaging Sealing Machine Manufacturers.

As a leading Packaging Sealing Machine Manufacturers with over 75 years of expertise since its founding in 1947, PAC Machinery specializes in innovative packaging machinery solutions that transform operations for global industries, including pharmaceuticals, medical devices, food processing, and e-commerce fulfillment. Headquartered in San Rafael, California, with manufacturing facilities in Berea, Ohio, and Milwaukee, Wisconsin, the company offers a comprehensive range of sealing machines, heat sealers, vacuum sealers, and bag sealers under renowned brands like Packaging Aids, Clamco, Rollbag, Vertrod, and Audion. These packaging sealing machine manufacturers focus on flexible, sustainable systems that enhance productivity, ensure package integrity, and extend product shelf life while minimizing costs and waste.

PAC Machinery upholds rigorous standards as trusted packaging sealing machine manufacturers, with its Milwaukee Bags and Materials division holding ISO 9001:2015 certification for quality management. Key achievements include launching validatable continuous band sealing machines like the Audion D542 AVTSV and AHSV models, designed for compliant medical and pharmaceutical applications with real-time monitoring and precise controls. The company has earned recognition for over six decades of reliable packaging machinery innovation, exhibiting at major events such as Pack Expo International and integrating advanced automation to meet OSHA hazardous area compliance.

With decades of hands-on experience as packaging sealing machine manufacturers, PAC Machinery has supported diverse clients, from onshoring U.S. manufacturing trends to optimizing high-volume fulfillment. Notable cases include seamless integration of Rollbag R3200 systems with CMES Robotics for AI-driven labeling, sorting, and sealing machines in e-commerce, reducing labor and shipping costs. Another success involves the PAC Rollbag R785 with MSD Kitamatic for compact, all-electric bag sealers in order fulfillment, boosting efficiency and sustainability across bakery, snacks, and industrial sectors.

Led by President Greg Berguig and a 50+ member team of packaging experts, PAC Machinery drives innovation in packaging sealing machine manufacturers through R&D focused on eco-friendly solutions. Highlights include the R3200 Paper automatic bagger for recyclable materials and validatable vacuum sealers like the PVK Med line, featuring gas flush for modified atmosphere packaging. These advancements, paired with virtual training and LiveDemo services, ensure scalable, user-friendly sealing machines that prioritize safety and repeatability.

Featured Products and Services

Heat Sealers: Continuous band systems for high-speed, hand-fed poly bag and pouch sealing.

Vacuum Sealers: Nozzle-style chambers for air removal and shelf-life extension in food and medical packaging.

Bag Sealers: Impulse and validatable models for secure closure of pre-made pouches and stand-up bags.

Continuous Band Sealers: Horizontal and vertical units for validated, compliant seals in pharmaceutical environments.

Founded in 1959 as a precision machine shop in Monrovia, California, Belco Packaging Systems, Inc. has evolved into a premier Packaging Sealing Machine Manufacturers on the West Coast, specializing in industrial shrink packaging equipment and medical tray and pouch sealers. With over 60 years of expertise, Belco delivers durable, high-quality heat sealing and shrink packaging solutions for diverse industries, backed by comprehensive warranties and worldwide reputation for reliability and performance up to 120 packages per minute.

Belco holds CE certification for its sealers and tunnels, ensuring compliance in global markets. Achievements include pioneering digital, PLC, and PC-controlled systems for precise process validation, RFID integration, and barcode reading capabilities. These innovations enable FDA-monitored environments with repeatable seals, earning recognition as an industry leader in Packaging Sealing Machine Manufacturers for clean-room proven equipment.

Boasting 35+ years in medical device packaging, Belco's solutions support clean-room tray sealing for implantable devices, while 60 years in food and bakery over-wrapping enhance tamper-evident graphics for products like pizzas and fruits. In pharmaceuticals, hot knife sealing ensures exact temperature control; printing/bindery cases feature the STC L-Sealer/Tunnel for efficient poster packaging; and automotive aftermarket applications protect brake kits with customizable shrink tunnels.

Family-owned and operated, Belco's team—led by Chairman & CEO Helen Misik, President Paul Misik, and V.P. of Sales Tom Misik—includes dedicated R&D (Manager Dave MacNeil) and product development experts (Manager Keith Bergen) fostering continuous innovation. Recent advancements like Smart Tunnel Control for even heat distribution and PC-monitored data acquisition drive efficiency in Packaging Sealing Machine Manufacturers.

Key Products and Services

L-Bar Sealers: Customizable semi-automatic to automatic heat sealing for shrink film compatibility.

Shrink Tunnels: Recirculating air systems with precise airflow for low-temperature operations.

Tray Sealers: Clean-room validated constant heat sealing for medical trays with process alarms.

Pouch Sealers: Table-top designs for Tyvek/Mylar pouches, including verification tools.

Blister Sealers: Two-station shuttles for point-of-purchase displays with minimal maintenance.

Starview Packaging Machinery, Inc., a premier packaging sealing machine manufacturer, was established in 1991 and is headquartered in Dorval, Quebec, Canada, with an additional facility in Carmel, Indiana, USA. As a privately held company with 51-200 employees, Starview specializes in innovative packaging machinery for high-visibility applications, including blister, clamshell, medical device, pharmaceutical, nutraceutical, food tray, and skin packaging. With over three decades as a trusted packaging sealing machine manufacturer, the company delivers standard and custom solutions worldwide through a network of authorized distributors, emphasizing robust designs and superior service to meet diverse industry needs.

Starview holds ISO 9001:2015 certification, ensuring high standards in quality management for its packaging sealing machine manufacturing processes. As a PMMI Legacy Member and Emerging Brand, it has earned recognition for excellence in the industry. Key milestones include the 2019 acquisition of Visual Packaging LP, expanding its footprint in plastic and carded packaging machinery, and launching a sustainable all-paper blister inline sealing machine, advancing eco-friendly packaging sealing solutions. The company consistently exhibits at major events like PACK EXPO and MD&M West, showcasing its leadership among packaging sealing machine manufacturers.

Boasting over 30 years as a packaging sealing machine manufacturer, Starview's management team brings more than a century of combined expertise in delivering customized systems for global clients. Notable cases include the successful Factory Acceptance Test (FAT) and shipment of the fully automatic BSC/PH8-1418 medical device tray sealer with robotic alignment, optimizing high-volume production. Another highlight is the deployment of high-speed inline conveyor blister packaging machines for efficient, large-scale blister sealing operations, reducing labor while maintaining uptime in pharmaceutical and food sectors.

Starview's in-house engineering team of skilled professionals drives innovation in packaging sealing machine manufacturing, designing turnkey automated systems with features like product descramblers and robotic infeeds for seamless integration. The focus on sustainability and customization—such as vacuum-assisted heat sealing and IQ/OQ validation—positions Starview at the forefront of evolving packaging technologies, supported by comprehensive training and payback analysis services.

Featured Products and Services

Blister Packaging Sealer: Custom heat seal tooling and IQ/OQ documentation

Clamshell Packaging Sealer: In-plant installation and line optimization analysis

Medical Tray Sealing Machine: Validation, calibration, and training services

Skin Packaging Machine: Die cutting integration and parts support

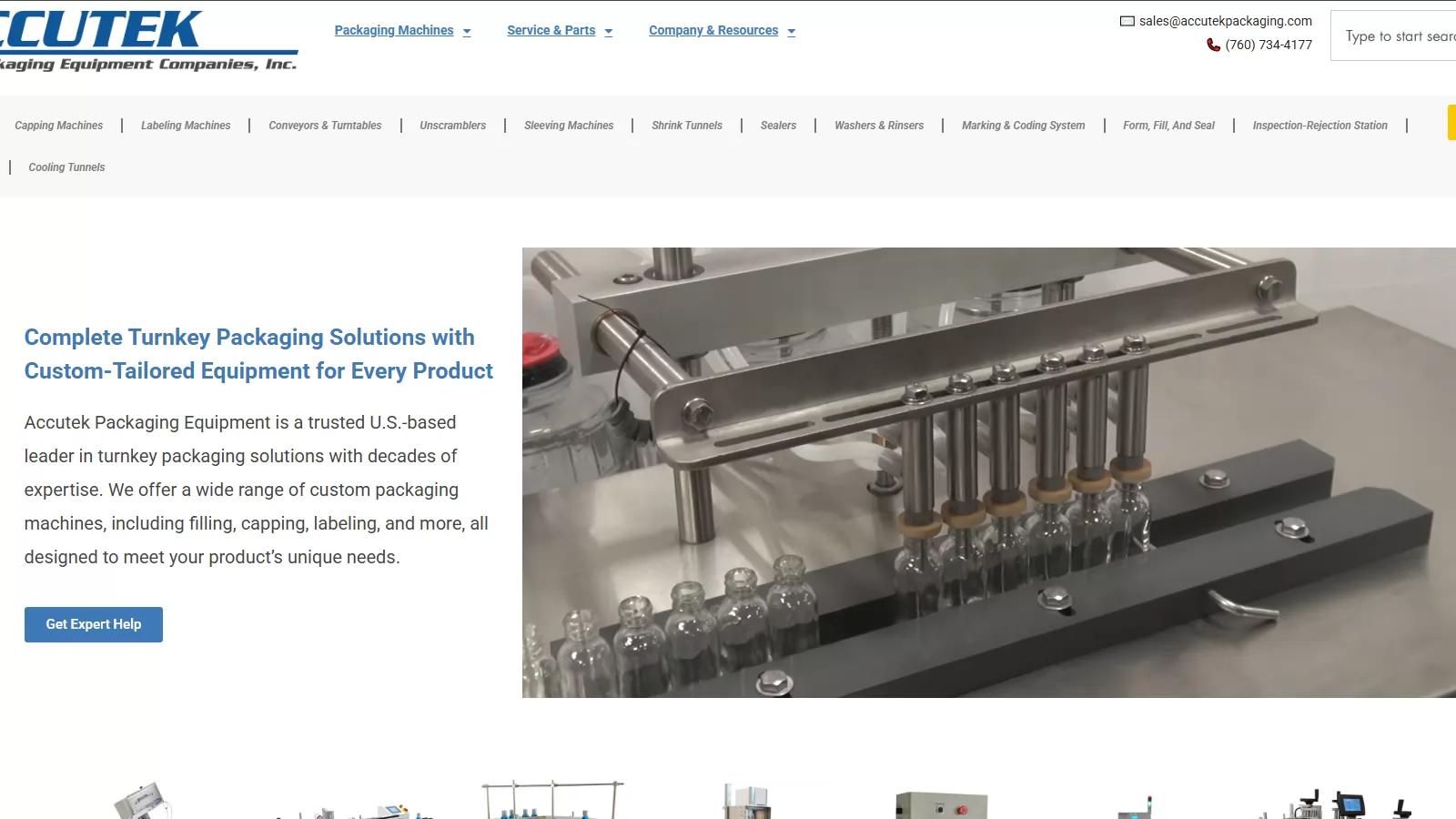

Accutek Packaging Equipment Company, Inc., established in 1989 in Vista, California, is a leading privately owned packaging sealing machine manufacturer in the United States, specializing in turnkey packaging solutions for industries including food, pharmaceuticals, cosmetics, chemicals, and beverages. As a trusted provider of comprehensive packaging systems, Accutek designs and builds equipment like liquid filling machines, capping machinery, labeling applicators, and sealing devices to ensure efficient, precise, and hygienic production lines. With facilities in California, Texas, and Florida, the company supports global clients through customized inline systems that handle diverse container types, from bottles to tubes, emphasizing user-friendly operation and rapid integration.

Accutek holds a strong reputation as one of the top packaging sealing machine manufacturers, backed by over 35 years of expertise and strategic acquisitions such as Labelette (2001) for advanced labeling technology, Kiss Packaging Systems (2001) for precision filling, and Biner Ellison (2003) for high-speed rotary equipment. These moves have expanded its portfolio, enabling tens of thousands of machines produced and sales milestones like $5 million by 1995. The company's commitment to quality is evident in its factory acceptance testing, one-year warranties on non-wear parts, and use of food-grade stainless steel for compliance with industry standards.

With decades of hands-on experience, Accutek has equipped Fortune 500 companies and small-scale manufacturers, delivering robust solutions for liquid filling, tube sealing, and shrink banding in high-volume settings. Notable examples include complete bottling lines for e-juice and sauces, where overflow fillers ensure foam-free precision, and automated case packing systems that streamline end-of-line operations for beverages and cleaners. Clients report equipment reliability lasting 10-20 years with minimal maintenance, supporting scalable production from benchtop to fully automated setups.

Accutek's 51-200 employee team includes factory-trained, certified technicians dedicated to installation, training, and ongoing support, fostering seamless customer integration. Innovation drives the company forward through engineer-led advancements like servo-driven fillers for exact dosing, bottomless conveyors for easy inspections, and multi-zone shrink tunnels for tamper-evident sealing. These developments, combined with programmable logic controls and vision systems, position Accutek as a forward-thinking packaging sealing machine manufacturer, continuously modernizing designs for sustainability and efficiency.

Key Products and Services

Packaging Sealing Machine: Tube sealing services for viscous products like creams and gels.

Capping Equipment: Secure closure services for bottles and jars in liquid packaging lines.

Shrink Tunnel Systems: Heat sealing services for sleeve labeling and neck banding applications.

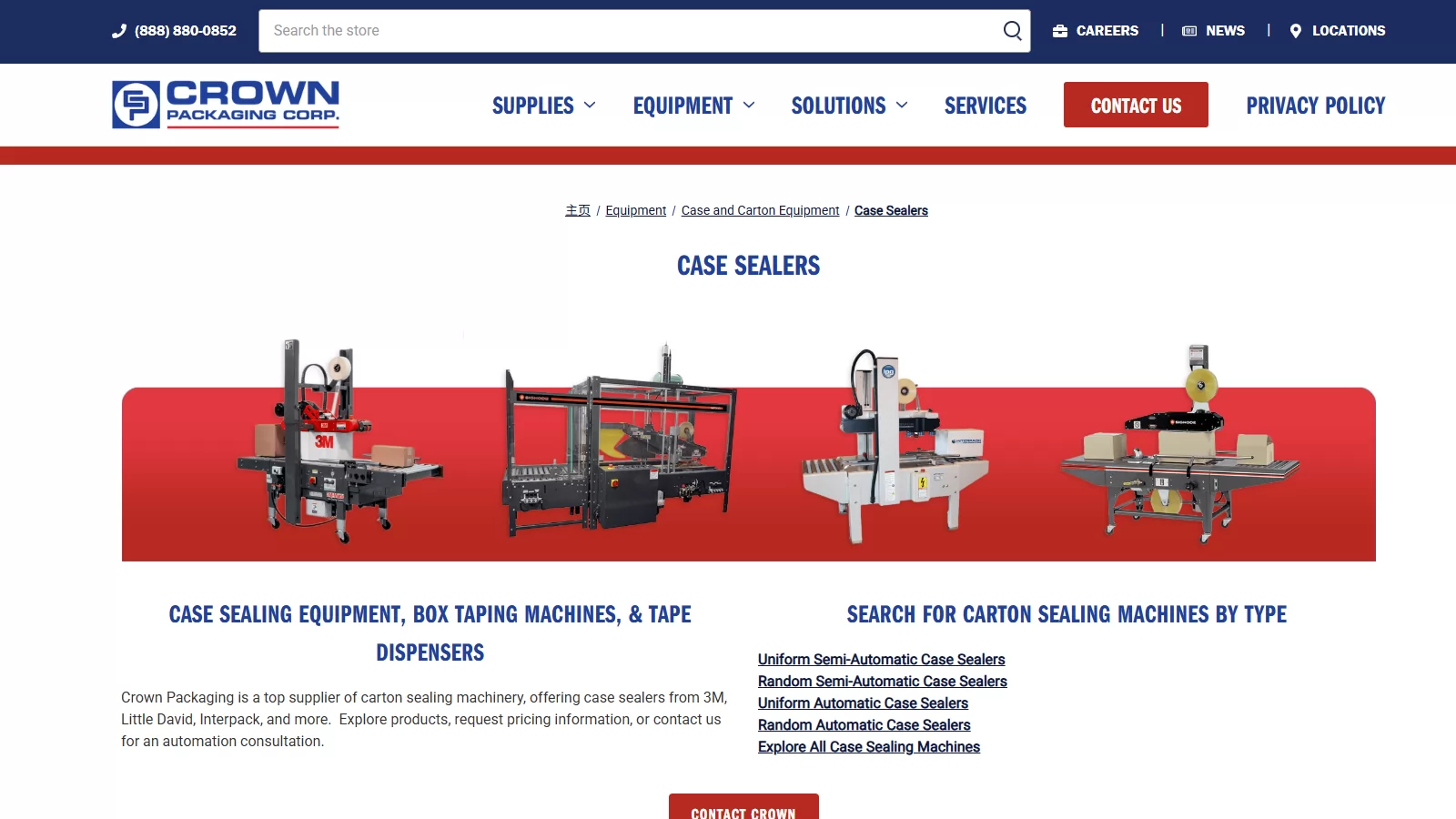

Crown Packaging Corp., established in 1969, stands as a premier Packaging Sealing Machine Manufacturers and single-source provider of industrial packaging solutions across North America. With over 50 locations in the US, Canada, and Mexico, this privately-held company serves thousands of customers—from global retailers and manufacturers to startups—offering more than 150,000 packaging supplies, advanced equipment, and tailored services. Specializing in packaging sealing machine manufacturers innovations, Crown delivers customized systems for carton sealing, automation, and sustainable materials, helping businesses streamline operations, reduce costs, and enhance efficiency in shipping and protection.

Certified under ISO 9001:2015 for customer satisfaction, inventory management, and supplier performance, Crown excels in quality assurance. It also holds ISTA and APASS testing certifications, validating packaging integrity for rigorous standards. As a sponsoring member of PMMI (the Packaging & Processing Machinery Association), Crown has garnered recognition as a top industrial packaging sealing machine manufacturers over 50+ years, powering innovations in sealing equipment manufacturers and earning acclaim for nationwide support and eco-friendly packaging machinery solutions.

Boasting 50 years as trusted packaging sealing machine manufacturers, Crown has transformed operations across sectors. In e-commerce, a consumer electronics leader integrated automated case sealers and void fill systems, slashing material costs and labor while boosting peak-season output. A global logistics firm adopted robotic palletizers and eco-friendly stretch wrappers, advancing sustainability and throughput. For pharmaceuticals, a producer leveraged vendor-managed inventory for cold-chain sealing machines, minimizing delays and expenses through just-in-time deliveries of insulated cartons and gel packs.

Crown's 200+ regional specialists—including engineers, service technicians, and corrugated experts—fuel cutting-edge advancements in packaging sealing machine manufacturers. From facility audits to full automation with AGVs, robotics, and conveyance, the team designs custom sealing equipment solutions, optimizing uptime, ergonomics, and sustainability. Partnerships with top packaging machinery manufacturers ensure access to state-of-the-art tools, driving real-time reporting and cost-saving integrations.

Key Products and Services

Case Sealers: automated carton sealing and integration

Strapping Machines: bundling and load securing

Stretch Wrappers: pallet stabilization and wrapping

Shrink Wrap Systems: film bundling and protection

Established as part of the TOPPAN Group in 1900, TOPPAN Packaging stands as a premier global provider of flexible and thermoformed packaging, renowned among Packaging Sealing Machine Manufacturers for integrating advanced heat-sealing technologies with barrier films and custom designs. Operating 22 facilities across North America, Latin America, and Europe, the company serves diverse sectors like food, medical, and retail, emphasizing lightweight, recyclable solutions that enhance product freshness, security, and shelf appeal while aligning with circular economy goals.

TOPPAN upholds ISO 13485 and ISO 9001 certifications, featuring Class 100,000 cleanrooms and annual OEM audits for precision in Packaging Sealing Machine Manufacturers processes. Key accolades include the 2025 AmeriStar Award for recyclable pet care packaging, gold at the Australasian Packaging Innovation & Design Awards for retortable PP mono-material pouches, and CDP’s Climate Change A List recognition for sustainability leadership.

Boasting over a century of expertise, TOPPAN delivers end-to-end solutions from ideation to commercialization, with proven applications in ovenable trays for frozen meals and clamshell designs for produce. Notable cases include the Nylabone Chew Toy refresh—featuring curbside-recyclable blister packaging—and EnviroServe™ Leafy Greens, which extends shelf life for salads via modified atmosphere technology, supporting major CPG brands in scalable, eco-efficient deployments.

A global team of 50,000+ experts in engineering, design, and R&D propels TOPPAN's innovations, such as the BOPP/BOPE hybrid production line for high-barrier, recyclable films and PaperBlister systems reducing plastic use in retail. Through co-creation hubs like “L・IF・E,” the team advances Packaging Sealing Machine Manufacturers capabilities, focusing on digital traceability and bio-based materials to foster sustainable supply chains.

Featured Products and Services

Packaging Sealing Machines: Precision heat-sealing for thermoformed medical and retail formats.

Barrier Film Solutions: High-performance laminates for extended food shelf life.

Recyclable Pouch Systems: Flexible stand-up designs with post-consumer recycled content integration.

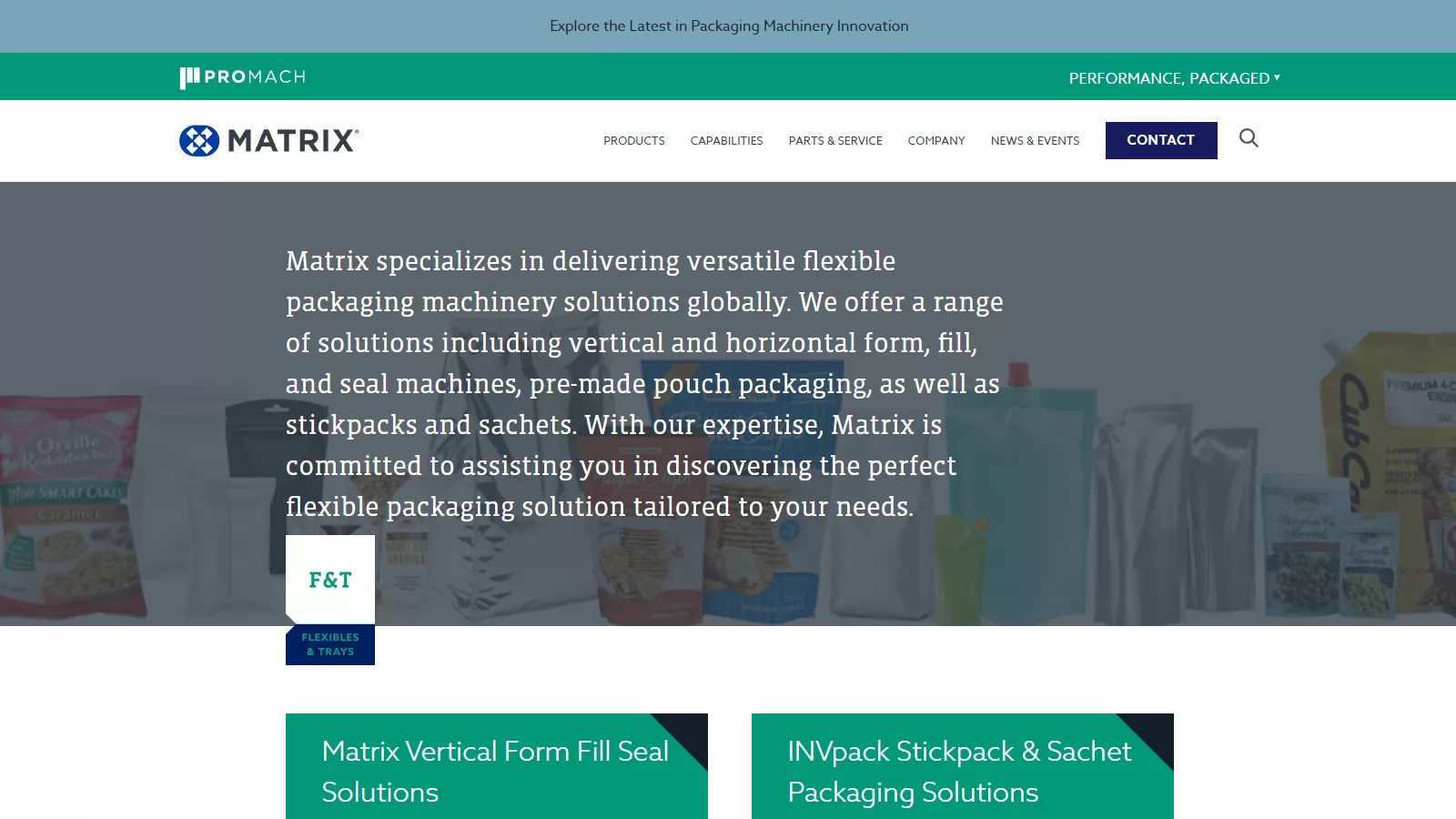

Matrix Packaging Machinery stands as a premier packaging sealing machine manufacturer, specializing in vertical form fill seal (VFFS) equipment and flexible packaging solutions. Founded in 1988 and headquartered in Grafton, Wisconsin, USA, the company operates as a ProMach brand, delivering rugged, well-engineered, cost-competitive, and user-friendly systems for global industries including food, beverage, pharmaceuticals, pet care, and consumer goods. With over 135,000 square feet of manufacturing space, Matrix focuses on vertical and horizontal form fill seal machinery, pre-made pouch systems, and stickpack/sachet solutions, ensuring efficient, hygienic, and versatile packaging sealing processes.

In terms of professional qualifications and achievements, Matrix excels through its PMMI Certified Trainer Program, where senior field service technicians provide expert, on-site training to minimize downtime, enhance safety, and boost productivity. This certification underscores the company's commitment to industry-leading standards in packaging machinery manufacturing. As a key player in flexible packaging, Matrix has earned recognition for reliable systems that support sustainable practices, such as compact designs compatible with eco-friendly films, and partnerships with innovators like INVpack and Pacraft (formerly Toyo Jidoki) for advanced sealing technologies.

Boasting more than 35 years of experience, Matrix has delivered transformative case studies, such as automating bagging for frozen meals to streamline high-volume production and collaborating on VFFS solutions for produce packaging that reduced labor costs for vertical packaging manufacturers. These projects highlight the company's expertise in integrating form fill seal systems with upstream processing for seamless operations across diverse applications.

Matrix's dedicated team, including innovative engineers and a world-class service network, drives continuous advancement in packaging sealing machine manufacturing. Highlights include zipper integration for enhanced product protection, Allen-Bradley or Beckhoff controls for high-speed efficiency up to 120 bags per minute, and collaborative R&D with partners like Yamato for on-site testing. This team-oriented approach fosters profitable, customized solutions that prioritize reliability and adaptability.

Key Products and Services:

Vertical Form Fill Seal Machines: Produce pillow, gusset, and flat bottom bags for food and non-food applications.

Pre-Made Pouch Packaging Systems: Automated loading, filling, and sealing for liquids and granules.

Stickpack and Sachet Sealing Machines: Single-serve formats with ultra-clean hygiene options.

Horizontal Form Fill Seal Pouchers: High-speed rotary systems for powders and valves up to 400 units per minute.

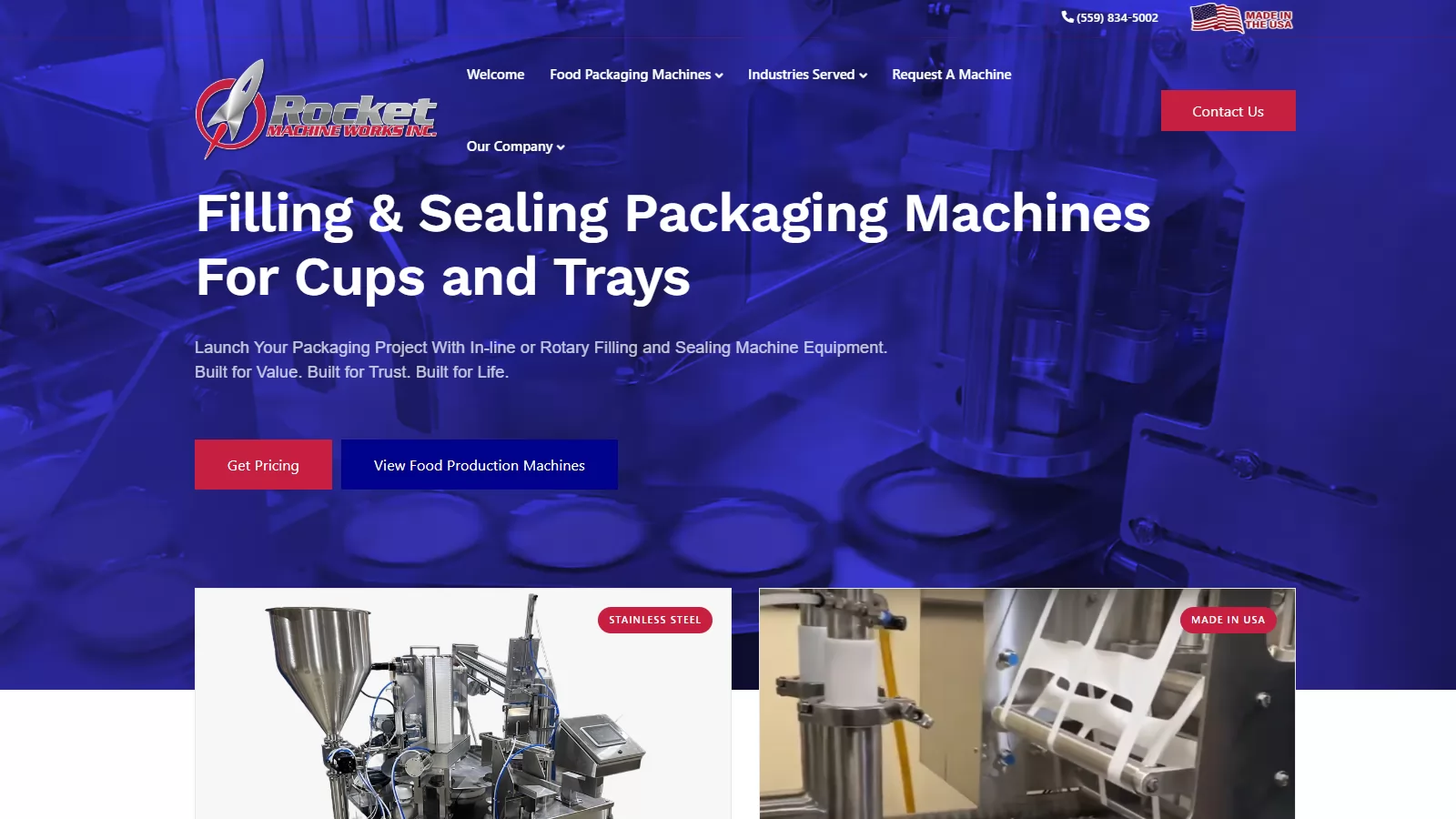

Rocket Machine Works, Inc., a premier packaging sealing machine manufacturers based in Fresno, California, has been delivering custom-engineered filling and sealing equipment for over 30 years. Specializing in rotary and inline packaging solutions for cups, trays, clamshells, and more, the company designs, manufactures, and assembles all machinery in-house to handle hot or cold products across food, beverage, hardware, and medical industries. As dedicated packaging sealing machine manufacturers, Rocket Machine Works ensures compliance with FDA, NSF, and USDA standards using stainless steel construction for durability and easy washdown, helping clients launch projects on time and within budget while minimizing downtime through PLC-controlled systems with remote access.

With decades of expertise in custom packaging sealing machine manufacturers' practices, Rocket Machine Works excels in high-output operations, producing machines that fill and seal up to 300 containers per minute. Achievements include fostering long-term client loyalty via reliable, low-maintenance equipment and participation in industry events like Pack Expo Las Vegas, where they showcase innovations in filling and sealing packaging equipment.

Boasting extensive experience as packaging sealing machine manufacturers, the company has served diverse applications, from yogurt and salads to ready-to-eat meals and sustainable trays. Notable cases include doubling production efficiency for Bobby Salazar’s Mexican Foods Inc., solving filling challenges for J&L Food Specialties, and supporting scalable solutions for Hello Fresh and Driscoll’s Strawberries, demonstrating proven impact in food processing and beyond.

Led by owner Mike vonHusen and a skilled engineering team, Rocket Machine Works drives innovation with quick-change carriers, advanced temperature controls, and expandable systems free of proprietary parts for seamless maintenance. Their focus on client collaboration ensures tailored filling and sealing packaging equipment that evolves with business needs.

Key Products and Services

Rotary Packaging Sealing Machines: Custom filling, sealing, and overcapping for high-volume cups and trays.

Tray Sealing Equipment: Versatile heat sealing for multi-compartment, microwave-safe containers with automated denesting.

Inline Filling and Sealing Systems: Flexible multi-lane solutions for salads, dips, and condiments in rigid packaging.

Starview Packaging Machinery, Inc., a premier packaging sealing machine manufacturer, was established in 1991 and is headquartered in Dorval, Quebec, Canada, with an additional facility in Carmel, Indiana, USA. As a privately held company with 51-200 employees, Starview specializes in innovative packaging machinery for high-visibility applications, including blister, clamshell, medical device, pharmaceutical, nutraceutical, food tray, and skin packaging. With over three decades as a trusted packaging sealing machine manufacturer, the company delivers standard and custom solutions worldwide through a network of authorized distributors, emphasizing robust designs and superior service to meet diverse industry needs.

Professional Qualifications and Achievements

Starview holds ISO 9001:2015 certification, ensuring high standards in quality management for its packaging sealing machine manufacturing processes. As a PMMI Legacy Member and Emerging Brand, it has earned recognition for excellence in the industry. Key milestones include the 2019 acquisition of Visual Packaging LP, expanding its footprint in plastic and carded packaging machinery, and launching a sustainable all-paper blister inline sealing machine, advancing eco-friendly packaging sealing solutions. The company consistently exhibits at major events like PACK EXPO and MD&M West, showcasing its leadership among packaging sealing machine manufacturers.

Experience and Cases

Boasting over 30 years as a packaging sealing machine manufacturer, Starview's management team brings more than a century of combined expertise in delivering customized systems for global clients. Notable cases include the successful Factory Acceptance Test (FAT) and shipment of the fully automatic BSC/PH8-1418 medical device tray sealer with robotic alignment, optimizing high-volume production. Another highlight is the deployment of high-speed inline conveyor blister packaging machines for efficient, large-scale blister sealing operations, reducing labor while maintaining uptime in pharmaceutical and food sectors.

Team and Innovation

Starview's in-house engineering team of skilled professionals drives innovation in packaging sealing machine manufacturing, designing turnkey automated systems with features like product descramblers and robotic infeeds for seamless integration. The focus on sustainability and customization—such as vacuum-assisted heat sealing and IQ/OQ validation—positions Starview at the forefront of evolving packaging technologies, supported by comprehensive training and payback analysis services.

Key Products and Services

Blister Packaging Sealer: Custom heat seal tooling and IQ/OQ documentation

Clamshell Packaging Sealer: In-plant installation and line optimization analysis

Medical Tray Sealing Machine: Validation, calibration, and training services

Skin Packaging Machine: Die cutting integration and parts support

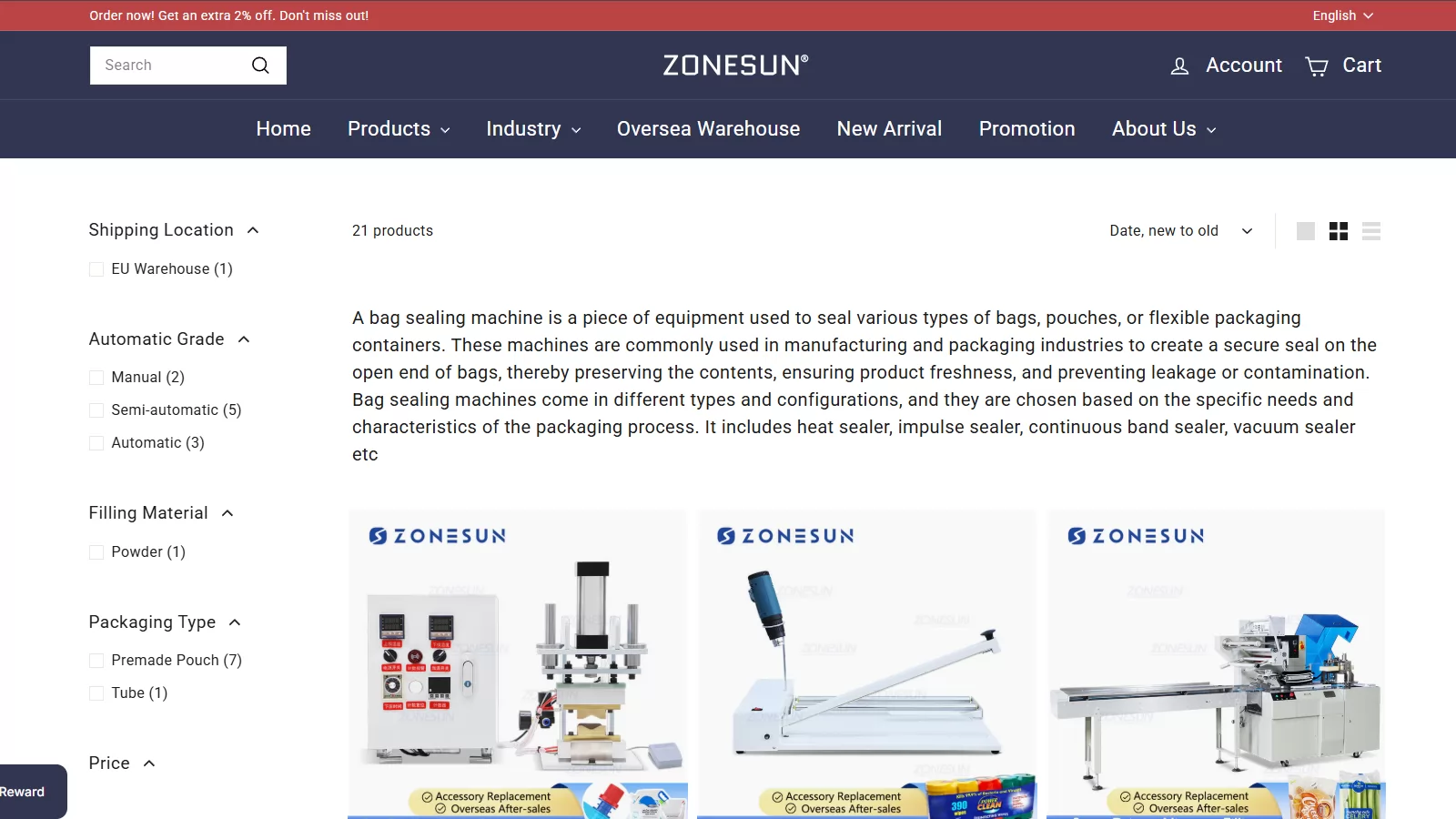

ZONESUN Technology Limited, officially Guangdong Shanghang Technology Co., Ltd., stands as a leading Packaging Sealing Machine Manufacturers and high-tech enterprise founded in 2014 with a registered capital of 10 million yuan. Headquartered in Foshan, Guangdong Province, China, the company excels in the research, development, production, sales, and technical services of advanced packaging machinery, including filling machines, capping machines, labeling machines, sealing equipment, and fully automated production lines. As a trusted Packaging Sealing Machine Manufacturers, ZONESUN provides comprehensive ODM and OEM solutions, delivering cutting-edge professional information, integrated packaging systems, and reliable logistics to global clients in the United States, Canada, Italy, Brazil, Russia, Europe, and beyond. With an expansive 50,000㎡ elevator factory equipped with over 300 processing tools, ZONESUN emphasizes diversified management, continuous innovation, and integrity to drive cross-border manufacturing excellence in the packaging industry.

ZONESUN holds prestigious CE certification, alongside multiple trademark registrations and national intellectual property invention patents secured from 2017 to 2019, underscoring its commitment to quality and compliance as a top Packaging Sealing Machine Manufacturers. The company's rapid ascent is marked by five relocations and seven business expansions, reflecting robust growth and market adaptability. Renowned for superior product variety, output efficiency, brand strength, competitive pricing, and exceptional service, ZONESUN has earned unanimous praise from international customers for its reliable filling capping labeling machines and sealing solutions, positioning it as a backbone in the global packaging machinery sector.

Boasting over a decade of hands-on expertise in packaging machinery, ZONESUN has honed its capabilities through diverse international projects, delivering tailored solutions for efficient production workflows. Notable cases include optimizing a series of filling and sealing equipment for a Korean client in April 2024, ensuring seamless installation and fine-tuning of automated lines for enhanced productivity. In June 2023, the team completed overseas debugging of packaging machines in South Korea within two intensive days, overcoming tight timelines with overtime dedication. Additionally, ZONESUN innovated a custom card filling, sealing, and slicing solution for specialized needs, demonstrating prowess in automated pouch filling and sealing processes that preserve product integrity across industries like food, cosmetics, and pharmaceuticals.

ZONESUN's dynamic team of over 200 professionals, including 52 specialized engineers, forms the core of its high-quality technical R&D, marketing, and management framework. Embracing a people-oriented philosophy with merit-based advancement, comprehensive insurance, and career development channels, the team fosters employee happiness while integrating global talent strategies. Innovation drives ZONESUN's evolution as a forward-thinking Packaging Sealing Machine Manufacturers, with bold technological pursuits in automated systems, customized sealing innovations, and adaptive management to meet evolving market demands. This relentless focus on R&D ensures pioneering advancements in filling capping labeling machines and sustainable packaging solutions.

Key Products and Services

Automatic Vacuum Bag Packaging Sealing Machine - Vacuum sealing services for food preservation and extended shelf life

Spout Pouch Sealing Machine - Custom pouch sealing for liquid and powder product containment

Aluminum Foil Sealing Machine - Induction sealing solutions for tamper-evident bottle packaging

Continuous Band Sealer - Heat sealing for high-volume continuous packaging lines

Ultrasonic Tube Sealing Machine - Precision tube sealing for cosmetic and pharmaceutical applications

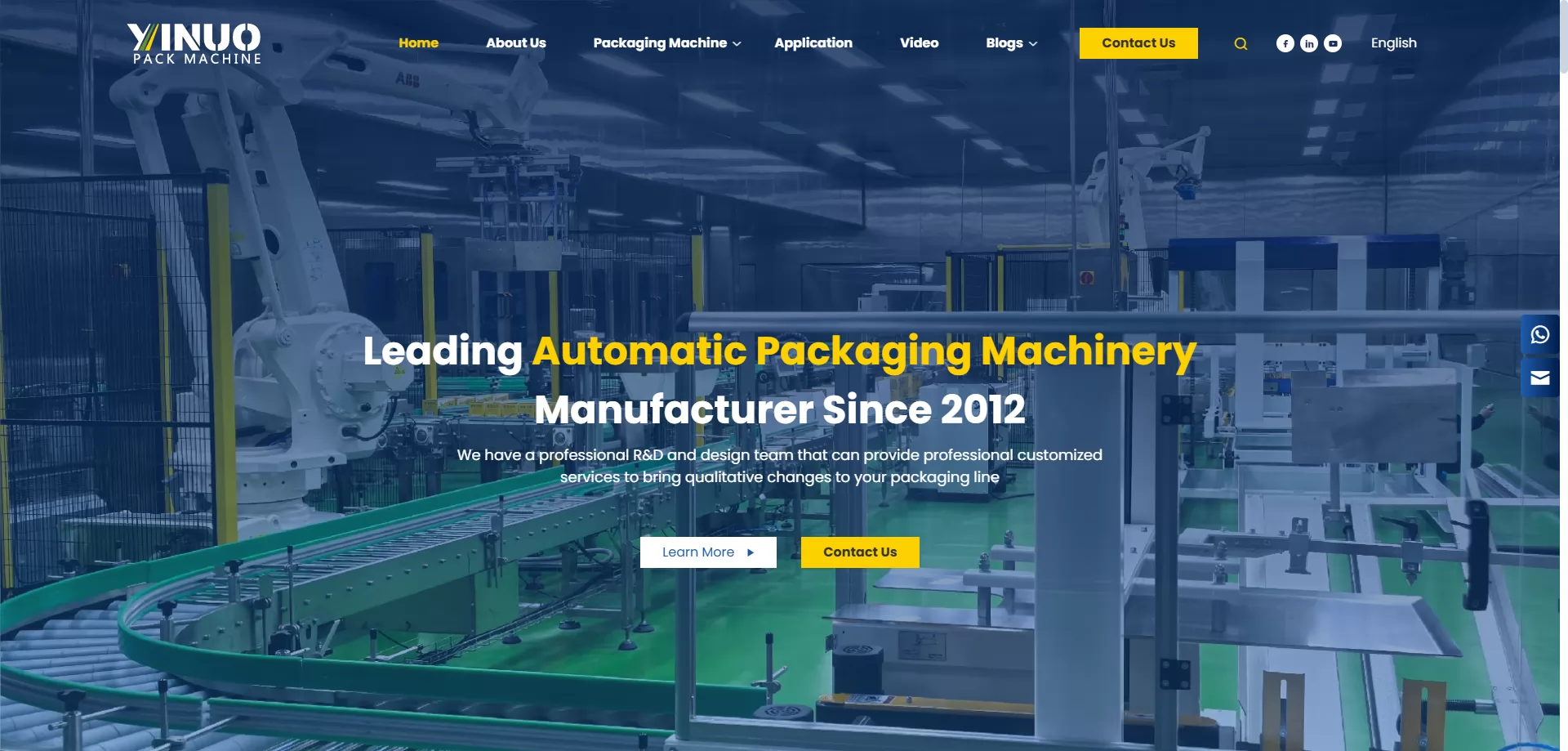

Wuhan Yijianuo Machinery Co., Ltd., established in 2012 and headquartered in Yangluo Development Zone, Wuhan, Hubei Province, China, is a prominent high-tech enterprise specializing in the design, production, and distribution of advanced automated packaging equipment. As one of the top Packaging Sealing Machine Manufacturers, the company focuses on intelligent filling and sealing solutions for the food and beverage, pharmaceutical, and consumer goods industries. With a state-of-the-art facility spanning over 10,000 square meters and more than 160 dedicated employees, Yijianuo delivers customized packaging lines for solids, liquids, powders, and granules, emphasizing efficiency, reliability, and sustainability in modern production workflows.

Certified with ISO9001 quality management standards and SGS Group verification, Yijianuo adheres to rigorous international protocols, ensuring every machine undergoes multi-stage testing for high-load stability and operational reliability. The company has earned global recognition for boosting client production efficiency by up to 30% through automated systems and achieving a 98% product qualification rate via full-process monitoring. Notable achievements include showcasing innovative packaging solutions at the 2024 Southeast Asia Food & Beverage Processing Exhibition in Vietnam and developing export-compliant lines for international markets.

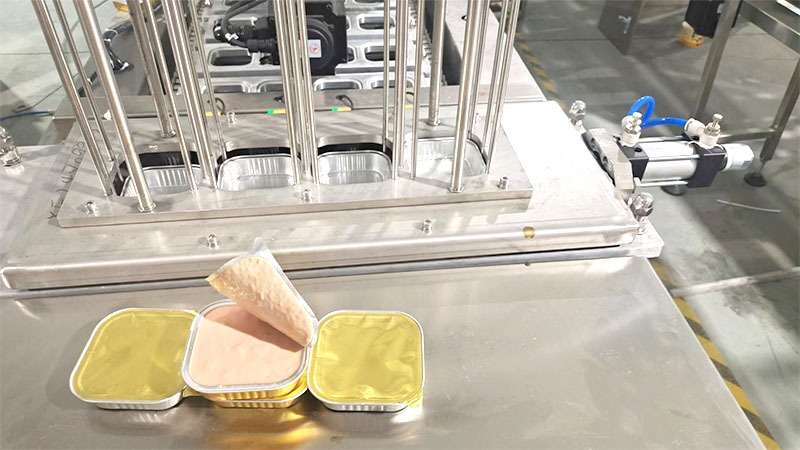

With over 12 years of specialized expertise in packaging machinery, Yijianuo has successfully deployed solutions for diverse applications, including ice cup packaging lines, instant noodle box sealing systems, and mixed nuts filling operations. Key cases feature high-speed vacuum tray packaging for processed meats and sausages, as well as customized spout pouch lines for dairy and sauces, reducing waste and enhancing consistency for global manufacturers.

Yijianuo's innovation-driven culture is powered by a robust R&D team of skilled engineers who collaborate with global material suppliers to pioneer eco-friendly technologies, such as intelligent management systems and UV sterilization integrations. This team fosters continuous upgrades, enabling tailored machines that cut energy use and support sustainable packaging practices.

Key Products and Services

Automatic Filling and Sealing Machine: Offers precise dosing, hermetic sealing, and leak detection for cups and trays.

Tray Sealing Machine: Delivers vacuum or modified atmosphere packaging for meats, seafood, and ready meals.

Spout Pouch Filling and Capping Machine: Provides automated filling, capping, and coding for liquids like yogurt and juices.

Thermoforming Vacuum Packaging Machine: Ensures high-speed tray forming, portioning, and secure sealing for granules and solids.

Choosing the right sealing machine requires aligning the manufacturer’s strengths with your specific industry requirements. Different companies excel in different sealing technologies, and understanding these distinctions is essential for making an informed purchase.

Carton & Case Sealers

For high-volume packaging, e-commerce, logistics, and warehouse operations.

Heat Sealing Machines

Widely used across food, medical, and consumer product industries for sealing films and flexible packaging.

Vacuum Sealing Systems

Essential for food preservation, pharmaceutical protection, and industrial components requiring moisture control.

Bag & Pouch Sealing Machines

Used for snacks, liquids, powders, and retail-ready packaging.

Form-Fill-Seal (FFS) Machinery

A fully automated solution for filling and sealing sachets, pouches, or bags.

Food & Beverage

Shelf-life extension, freshness preservation, leak prevention, and hygiene compliance drive demand.

Pharmaceuticals & Medical Devices

Sterile barrier requirements and strict regulatory standards necessitate consistent, validated sealing.

Consumer Goods

Flexible packaging growth calls for rapid, versatile heat-sealing systems.

E-Commerce & Logistics

Booming parcel shipments increase demand for fast, reliable case sealers.

Industrial Manufacturing

Heavy-duty and large-format products require robust, customizable sealing equipment.

By aligning the machine type with your industry needs, you can more easily determine which Packaging Sealing Machine Manufacturers best suit your required performance specifications.

The packaging machinery landscape is rapidly evolving, with 2025 marking a year of transformative technological developments. These trends influence both buyer expectations and manufacturer innovation strategies.

Modern packaging lines rely on high-level automation to reduce labor costs and improve consistency. Leading sealing machines now include:

IoT-enabled monitoring

Self-diagnostic and predictive maintenance

Smart sensors for sealing accuracy

Integrated robotics for carton feeding and product handling

Such advancements increase throughput while reducing downtime and operational costs.

Environmental responsibility is a growing priority. U.S. manufacturers are responding with:

Energy-efficient sealing systems

Machines optimized for recyclable and bio-based materials

Reduced film and tape consumption technologies

These efforts contribute to lower operating costs and improved environmental performance.

As product variety increases across industries, manufacturers demand flexible sealing machines capable of:

Fast changeover between product sizes

Random size carton sealing

Multi-format pouch sealing

Modular upgrades

This flexibility helps businesses remain competitive in fast-moving markets.

Purchasing a sealing machine is a strategic decision that affects productivity, product quality, and total operational cost. Below are essential considerations for selecting the right partner.

What packaging materials do you use?

Do you need carton, pouch, heat, or vacuum sealing?

What is your required production speed?

Are there size variations or unique product configurations?

Understanding your needs shortens the selection process and ensures compatibility.

Key features to analyze include:

Sealing accuracy and consistency

Machine durability

IoT capability and automation level

Safety compliance

Integration with existing conveyors or packaging lines

Advanced technologies often result in higher uptime and lower long-term costs.

Even high-performance sealing machines require routine service. Factors affecting TCO include:

Spare part availability

Technical support responsiveness

Maintenance complexity

Energy consumption

Operator training

A machine with a slightly higher initial cost may deliver better ROI if it offers greater uptime and lower long-term expenses.

In 2025, U.S. Packaging Sealing Machine Manufacturers continue to lead the global market with innovation, automation, sustainability, and enhanced production safety. Whether your business operates in food packaging, pharmaceuticals, consumer goods, or e-commerce fulfillment, selecting the right manufacturer can significantly improve efficiency, reduce costs, and strengthen product protection.

By understanding the latest trends, comparing machine categories, and evaluating specific operational needs, you can make a confident and strategic decision when choosing your sealing equipment partner. As global packaging demands continue to rise, aligning with a reputable and forward-thinking U.S. manufacturer will help ensure long-term success.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.