The tray sealing equipment market in the United States continues to expand in 2025, driven by rising demand across food packaging, ready-made meals, medical supplies, and industrial applications. As sustainability standards tighten and automation becomes essential for operational efficiency, companies are increasingly prioritizing high-performance tray sealing machines that offer reliability, precision, and compatibility with modern production lines.

This “Top 10 Tray Sealing Machine Manufacturers in the USA 2025” guide is designed to help buyers, engineers, and decision-makers better understand the leading suppliers shaping the American tray sealing market. Rather than relying on outdated or inaccurate rankings, this guide highlights industry trends, selection factors, and reputable U.S. manufacturers recognized for their contributions to packaging technology. Whether you operate in food processing, pharmaceuticals, or beverage packaging—including systems related to Cup Filling and Sealing Machine production—this resource provides a clear starting point for informed procurement decisions.

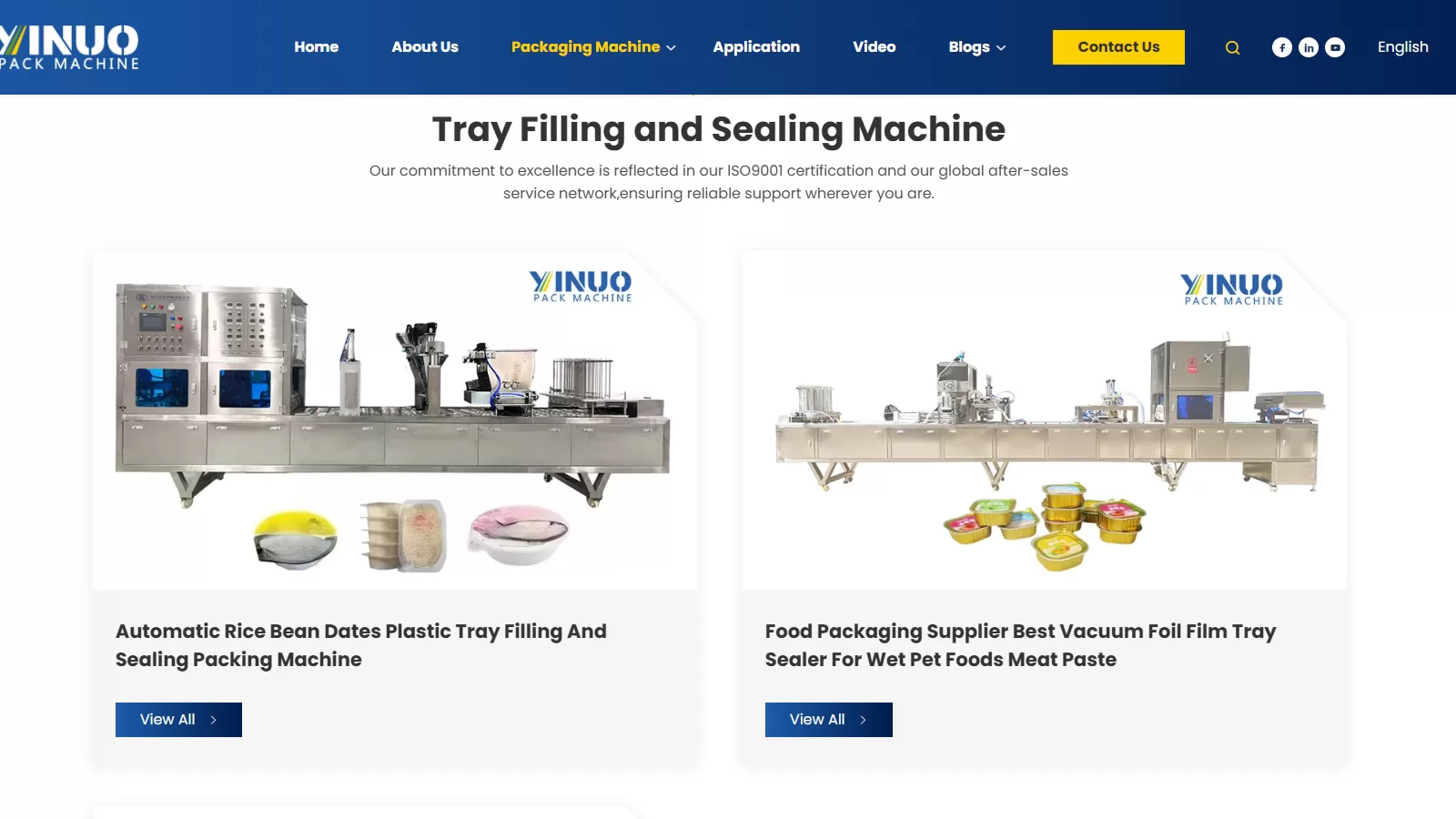

Wuhan Yijianuo Machinery Co., Ltd., established in 2012 and headquartered in Yangluo Development Zone, Wuhan, Hubei Province, China, is a prominent tray sealing machine manufacturer specializing in automated packaging solutions for the food, beverage, pharmaceutical, and daily chemical industries. With a factory spanning over 9,600 square meters and a workforce exceeding 160 employees, the company integrates research, design, production, and sales to deliver high-precision filling and sealing equipment. Its core focus lies in tray sealing machines that ensure hygienic, efficient packaging for products like ready meals, dairy, and processed meats, emphasizing customized automation to enhance productivity and product freshness.

Professional Qualifications and Achievements

Certified under ISO 9001 for quality management, Yijianuo excels as an OEM/ODM provider with three dedicated production lines and an annual output value between US$2.5 million and US$5 million. Since beginning exports in 2017, it has reached markets across North America, Southeast Asia, Europe, and Africa, capturing 31-40% of its revenue from international sales. Notable achievements include showcasing vacuum tray sealing systems at the 2024 Southeast Asia Food & Beverage Processing Exhibition in Vietnam and launching an innovative ice hockey puck packaging line in 2025, demonstrating its commitment to global standards and turn-key engineering services.

Experience and Cases

Boasting over a decade of expertise in tray sealing machine manufacturing, Yijianuo has engineered comprehensive production lines integrating filling, vacuuming, and leak detection for diverse applications. Key cases include automated tray sealing solutions for sausages and processed meats, ensuring high-speed vacuum packaging that meets export compliance, and customized filling lines for dairy products and sauces demonstrated at international expos. The company provides end-to-end support, from factory design to installation and training, fostering long-term client partnerships worldwide.

Team and Innovation

Yijianuo's innovation-driven approach is powered by an 11-20 member R&D team, leveraging mechanical, electronic, and microcomputer technologies to develop energy-efficient, intelligent systems that minimize downtime and ensure consistent quality. Recent innovations, such as multihead weigher-integrated nut cup sealing machines and adaptive thermoforming tray sealers, reflect its focus on customization and sustainability, enabling clients to scale operations seamlessly.

Best Products

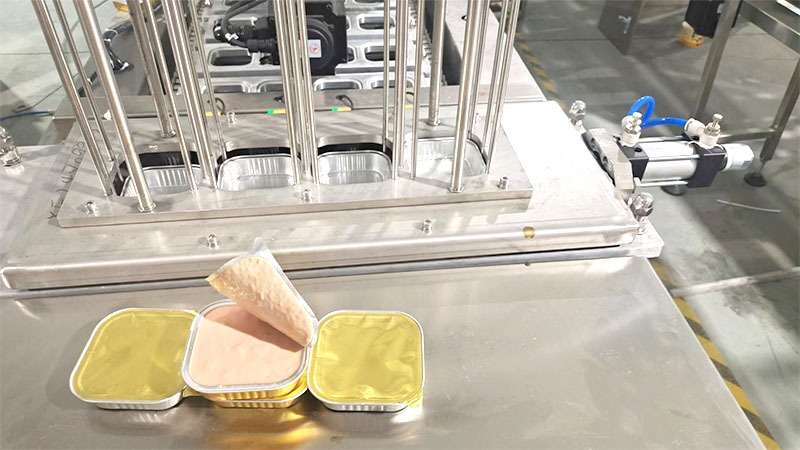

Tray Sealing Machine: Automated filling, vacuum sealing, and leak detection services for food trays.

Thermoforming Packing Machine: Custom forming, portioning, and secure sealing services for vacuum trays.

Automatic Aluminum Foil Tray Filling and Sealing Machine: Precision dosing, foil application, and UV sterilization services for ready-to-eat meals.

JBT Marel Corporation, formerly JBT Corporation, is a leading global technology solutions provider specializing in high-value segments of the food and beverage industry. With roots tracing back to 1884 as the Bean Spray Pump Company, the firm has evolved into a powerhouse in food processing machinery, designing, manufacturing, testing, and servicing advanced systems for meat, seafood, poultry, ready-to-eat meals, bakery, juice, dairy, and fruit/vegetable products. Through its FoodTech division and the 2019 acquisition of Proseal, JBT Marel excels as a premier tray sealing machine manufacturer, delivering flexible, high-throughput solutions that ensure product freshness and supply chain integrity.

Professional Qualifications and Achievements

JBT Marel holds a storied legacy of innovation, with over 140 years of engineering excellence and a commitment to sustainability outlined in its ESG reports. As a tray sealing machine manufacturer, Proseal has installed more than 8,000 units worldwide, earning accolades like the 2024 AgTech Breakthrough Award for its Case DeStacker and the Made in Britain designation for superior design and installation expertise. These achievements underscore the company's role in reducing plastic waste—up to 10 tons per million trays sealed—while adhering to global standards for food safety and efficiency.

Experience and Cases

Boasting decades of hands-on expertise in tray sealing machine manufacturing, JBT Marel has powered production lines for multinational clients. Key cases include the Proseal GT5eX ultra-high-speed line for soft fruit top sealing, which minimizes product waste and captures overweight punnets; the GT5 system for automatic filling, sealing, and gas flushing of multi-component salad bowls; and the GT2 setup for Bakkavor Group, achieving 120 packs per minute for multi-component meals while slashing operator activity by 69%. These implementations highlight proven scalability and reliability in diverse tray sealing applications.

Team and Innovation

JBT Marel's global workforce of about 5,200 professionals—spanning engineering, software, automation, and R&D—fosters a culture of collaboration and adaptability. Innovation drives tray sealing machine advancements, such as intuitive, eco-friendly electric seal actuation, modular add-ons for gas flush (MAP), vacuum gas, and skin packaging, plus quick-changeover robotics for reduced downtime. This team-centric approach ensures customized, future-proof solutions that optimize resource use and meet evolving demands in tray sealing machine manufacturing.

Best Products

Tray Sealing Machines with Gas Flush: Packaging line integration and maintenance services.

Vacuum Gas Tray Sealers: Custom installation and technical support.

Skin Packaging Systems: Turnkey deployment and training programs.

Oliver Packaging and Equipment Company, a premier tray sealing machine manufacturer, has been at the forefront of innovative food packaging solutions since its founding in 1890 by Thomas Oliver. Headquartered in Grand Rapids, Michigan, the company specializes in bakery equipment and advanced meal packaging systems, particularly high-performance tray sealing machines designed to preserve food freshness, enhance efficiency, and support large-scale operations in the food service industry. As a trusted tray sealing machine manufacturer, Oliver integrates durable meal trays, sealing films, and automated systems to streamline packaging for schools, senior care, restaurants, and grocery stores, helping clients feed communities with reliable, leak-proof solutions.

Professional Qualifications and Achievements

With over 90 years of expertise as a tray sealing machine manufacturer, Oliver holds a legacy of pioneering innovations, including the debut of the first retail bread slicing machine in 1932 and the Senior Meals Packaging System in 2000. The company has earned recognition for its leadership in pre-prepared meal packaging and bakery equipment markets, recently highlighted as a 2024 Q4 Top 100 Notable Deal following its acquisition by Monomoy Capital Partners. Employee testimonials on platforms like Glassdoor and Indeed praise Oliver's thoughtful leadership under CEO Mitch Summerfield, fostering a supportive culture that prioritizes work-life balance and professional growth, making it one of the most valued employers in the packaging sector.

Experience and Cases

Oliver's 25-year partnerships with senior meal providers and school nutrition programs demonstrate its proven track record as a tray sealing machine manufacturer. Notable cases include equipping White Cloud Public Schools with the Speedseal CX Model 1308 for rapid grab-n-go packaging of salads, sandwiches, and entrees, sealing up to 8 packages per minute while ensuring stackable, tamper-evident security. Similarly, collaborations with Meals on Wheels programs utilize Oliver's systems to package thousands of daily meals, reducing labor costs and maintaining nutritional integrity for vulnerable communities.

Team and Innovation

Oliver's dedicated team of manufacturing experts and 24/7 support specialists drives continuous advancement in tray sealing technology. Innovations like patented tray designs for leak prevention and high-speed conveyor systems (up to 140 trays per minute in the Speedseal MX series) reflect the company's commitment to sustainability, including compostable options. Under strong leadership, the team collaborates closely with clients as an extension of their operations, delivering customized tray sealing machine manufacturing solutions that evolve with industry demands.

Best Products

Tray Sealing Machines: Automated sealing for efficient meal packaging and freshness preservation

Meal Packaging Systems: Integrated conveyors and denesters for high-volume food tray production

Compostable Food Trays: Eco-friendly, single-use containers with film lidding for sustainable delivery

Bakery Equipment: Precision slicers and dough processors paired with sealing solutions for retail operations

Reepack, a premier Italian tray sealing machine manufacturer founded in 1997, specializes in high-quality flexible and tray packaging solutions for food, healthcare, and industrial sectors. Headquartered in Seriate, Italy, with a German branch and as a ProMach brand, Reepack delivers innovative machinery like tray sealers, thermoformers, vacuum chambers, and flow wrappers to preserve consumable products through advanced tray sealing technologies.

Professional Qualifications and Achievements

Certified under ISO 9001:2015 for quality management and ISO 45001:2018 for occupational health and safety, Reepack upholds rigorous standards in tray sealing machine production. Its ReeNEXT IoT platform is Industry 4.0 compliant, enhancing digital efficiency in packaging lines. Recognized for market leadership, Reepack drives growth in competitive tray sealing applications, supporting sustainable preservation for global clients.

Experience and Case Studies

With over 25 years in tray sealing machine manufacturing, Reepack serves diverse industries including fresh produce, poultry, seafood, and medical devices. Notable examples include high-volume case-ready packaging for red meat processors using MAP-enabled tray sealers, and VSP solutions for retail-ready fruits and vegetables, ensuring extended shelf life without product deformation.

Team and Innovations

Reepack's international team of packaging experts embodies integrity and creativity, fostering innovations like configurable tray sealing systems integrated with automation tools. The ReeNEXT platform revolutionizes tray sealing operations with real-time monitoring, boosting productivity in MAP and VSP workflows.

Key Products

Semi-Automatic Tray Sealing Machines: Sealing services for diverse tray materials in fresh protein packaging.

Automatic Tray Sealing Machines (Entry-Level): Output optimization for small-medium tray sealing lines with MAP integration.

Automatic Tray Sealing Machines (High-End): High-performance VSP services for large-scale fresh food production.

ReeMaster NextGen Tray Sealing Machines: Precision sealing and automation for multi-shift tray packaging operations.

Company Overview

Ross Industries, Inc., a premier tray sealing machine manufacturer, specializes in designing, engineering, and producing advanced food processing and packaging equipment. Founded in 1968 and headquartered in Midland, Virginia, the company focuses on meat, poultry, seafood, pet food, and produce sectors, delivering durable, high-performance machinery crafted from premium stainless steel and aluminum. As a trusted tray sealing machine manufacturer, Ross emphasizes solutions that enhance product quality, food safety, and operational efficiency, including tray sealing machines for modified atmosphere packaging (MAP) and vacuum skin packaging to extend shelf life and preserve freshness.

Professional Qualifications and Achievements

With over 55 years of expertise, Ross holds an international reputation for innovation in tray sealing machine manufacturing, supporting legacy equipment without planned obsolescence and forging strategic partnerships with complementary brands. The company's machinery meets rigorous industry standards for hygiene and reliability, earning acclaim for pioneering tools like the original mechanical meat tenderizer. Ross has been recognized at events such as Process Expo 2023, where it showcased cutting-edge tray sealing advancements, solidifying its status as a go-to provider for high-yield packaging solutions.

Experience and Case Studies

Ross boasts decades of hands-on experience in tray sealing machine manufacturing, starting with its inaugural 1968 sale of a bone-in meat tenderizer to early adopter Charles Wible, which revolutionized non-chemical tenderization. In packaging, collaborations like the 2012 launch of the INPACK IN50 inline tray sealer with Reiser demonstrated superior leak-proof seals and tamper-evident features for fresh proteins, boosting shelf life in real-world applications for pork, poultry, and seafood processors. These implementations have helped clients minimize waste and maximize productivity across global supply chains.

Team and Innovation

Led by founder Henry "Bud" Ross, an inventive engineer whose garage-born ideas evolved into industry staples, the 51-200 member team excels in technical fabrication, sales, and R&D. This collaborative workforce drives innovations like efficient, flexible tray sealing machines with multi-benefit designs, such as T-shaped incisions for precise processing. Ross invests in ongoing enhancements, including inline systems for high-volume MAP and vacuum skin packaging, ensuring adaptability to evolving demands in tray sealing machine manufacturing.

Best Products and Services

Semi-automatic tray sealer: Tray sealing for small-scale modified atmosphere packaging.

Inline tray sealing machine: High-volume vacuum skin packaging for extended shelf life.

Automated MAP tray sealer: Flexible lid sealing services for fresh produce and proteins.

Established in 1990 with roots in the late 1970s, Design Machine & Manufacturing (DMM Packaging, Inc.) is a premier provider of custom-engineered packaging solutions, specializing as tray sealing machine manufacturers. Based in Kingsburg, California, the company designs, manufactures, integrates, and installs high-speed, sanitary packaging machinery tailored for diverse industries, including dairy, fertilizer, and chemicals. Emphasizing flexibility for multi-product lines, corrosion-resistant construction, and reduced personnel needs, DMM delivers affordable tray sealing machines and complete packaging systems using advanced materials like 316L stainless steel and nonferrous metals to ensure durability in extreme environments.

Professional Qualifications and Achievements

As expert tray sealing machine manufacturers, DMM holds pioneering credentials in sanitary-compliant designs, including some of the first Dairy 3-A approved packaging machines developed in consultation with industry sanitary boards. Their equipment achieves exceptional longevity, with case packers and tray sealers exceeding 23 million operational cycles without failure. Recognized for innovation in corrosion-resistant tray sealing solutions, the company integrates three-dimensional computer modeling for precise virtual simulations, ensuring compliance with stringent food safety and industrial standards.

Experience and Case Studies

With over three decades as tray sealing machine manufacturers, DMM has extensive experience adapting machinery for high-speed, sanitation-focused operations. In the early 1990s, they engineered custom tray sealing and packaging lines for the commercial fertilizer and chemical sectors, prioritizing extreme durability. A landmark case in 2003 involved entering the dairy industry, where DMM designed innovative Drop-Thru case packers enabling continuous sanitation runs—machines still in use today after millions of cycles. These projects highlight their ability to deliver versatile tray sealing machines that minimize downtime and support frequent product changes across food and industrial applications.

Team and Innovation

DMM's 20+ member team, led by Founder & CFO Abraham Wiebe, President Nick Wiebe, and Vice President Josh Wiebe, combines engineering expertise with roles in design, sales, and assembly, including Chief Design Engineer John Zweigle and Electrical Engineering Manager Matthew Cantu. Driving innovation as tray sealing machine manufacturers, they pioneer features like virtual issue simulation via 3D modeling and sanitation-optimized constructions, fostering efficient, low-maintenance packaging advancements that evolve with industry demands.

Key Products and Services

Tray Sealing Machines: Custom engineering and installation for high-speed food packaging

Case Packers: Sanitary-compliant integration for dairy and chemical lines

Cartoners: Flexible design and simulation for multi-product efficiency

Tray Packers: Corrosion-resistant manufacturing and aftermarket support

Rocket Machine Works Inc., a trusted name among tray sealing machine manufacturers, is headquartered in Fresno, California, where it has been designing and building custom-engineered packaging equipment for over 30 years. Specializing in filling and sealing solutions for cups and trays, the company focuses on rotary and inline tray sealers tailored for the food processing industry. All tray sealing machines and related equipment are 100% made in the USA, utilizing stainless steel construction for durability and compliance, ensuring seamless integration into high-volume production lines.

Professional Qualifications and Achievements

As certified tray sealing machine manufacturers, Rocket Machine Works adheres strictly to FDA, NSF, and USDA standards, guaranteeing hygienic and reliable performance in food packaging applications. Key achievements include delivering equipment that doubles production efficiency for clients, backed by a one-year parts warranty and six months of labor support. The company's commitment to quality has earned it a reputation for minimal downtime and nationwide installations, with participation in major events like PACK EXPO Las Vegas.

Experience and Case Studies

With decades of expertise in tray sealing machine manufacturing, Rocket Machine Works has solved complex food packaging challenges, reducing labor costs and enhancing productivity. Notable cases include:

For Bobby Salazar’s Mexican Foods Inc., custom tray sealers streamlined operations, doubling output while maintaining low maintenance.

Delori Products praised the team's innovative tray filler-sealer designs for honest, efficient solutions.

J&L Food Specialties benefited from cost-effective tray sealing systems that addressed filling inconsistencies.

Team and Innovation

The California-based Rocket Team excels in custom engineering for tray sealing machines, drawing on deep industry contacts to innovate user-friendly features like quick-change tray carriers and advanced temperature controls for superior seals. Their focus on expandable, washdown-compatible systems drives ongoing advancements in tray sealer technology, prioritizing client-specific needs.

Key Products and Services

Tray Sealing Machines: Custom design and installation for versatile foil and film sealing.

Continuous Motion Tray Sealers: High-speed inline filling and sealing for food trays.

Die Cut Tray Sealers: Efficient scrap management and hand-loaded packaging solutions.

Tray Filler-Sealers: Integrated filling, denesting, and sealing for rigid containers.

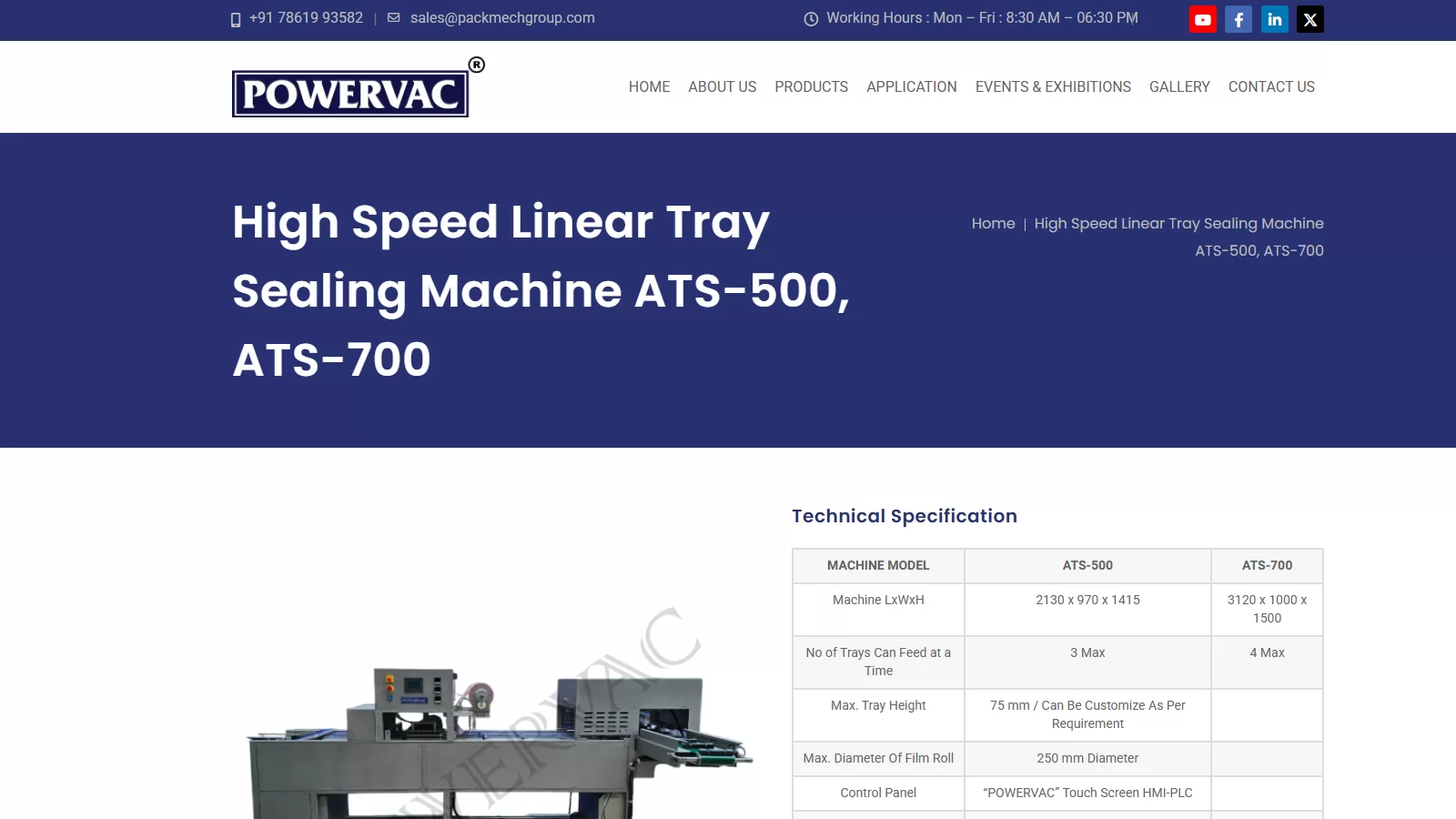

Packmech Engineers, established in 1995 as a sole proprietorship in Ahmedabad, Gujarat, India, operates under the POWERVAC brand within the PACKMECH GROUP. Specializing in tray sealing machine manufacturing, the company designs and produces high-quality vacuum packaging solutions for food, pharmaceuticals, and consumer goods industries. With a 35,000 sq. ft. state-of-the-art facility at Plot 520, Road 14, GIDC, Kathwada, Packmech Engineers delivers end-to-end services including custom design, manufacturing, installation, and maintenance of tray sealing machines, ensuring extended shelf life through advanced Modified Atmosphere Packaging (MAP) technology. Employing 51-100 skilled professionals, the firm exports globally, boasting 500 annual installations and 50 monthly dispatches as a premier tray sealing machine manufacturer in India.

Professional Qualifications and Achievements

With 30 years of expertise in tray sealing machine manufacturing, Packmech Engineers upholds stringent quality controls from raw material sourcing to final inspections, adhering to international standards for durability and precision. The company holds GST registration (24BAKPP1655H1ZM) and IEC (0817502386), enabling seamless global trade. Notable accolades include the Trend Setter Award, SME Excellent Award, Global Business Achievement Award, and Udyog Rattan Award, recognizing its leadership in vacuum tray sealing innovations and contributions to the packaging sector.

Experience and Case Studies

Leveraging three decades in tray sealing machine manufacturing, Packmech Engineers has served diverse applications, from sweets and dehydrated vegetables to basmati rice, dry fruits, and cheese portions up to 25 kg. Real-world implementations include MAP tray sealing for ready-to-eat snacks, reducing oxygen levels for freshness, and bulk vacuum packaging for pulses, demonstrating efficiency in retail and industrial scales across Indian and multinational clients.

Team and Innovation

Led by Director Sandip Panchal and CEO Bhartiben Ashok Panchal, the dedicated team of engineers and technicians drives continuous innovation in tray sealing machine manufacturing. By integrating cutting-edge MAP and thermoforming technologies, Packmech Engineers develops customized, indigenous solutions for enhanced efficiency, competing internationally while maintaining a robust domestic network of field executives for prompt support.

Key Tray Sealing Machine Products and Services

Automatic Tray Sealing Machine: Gas flushing and vacuum sealing for food preservation.

MAP Tray Sealer: Modified atmosphere packaging for extended shelf life.

Rotary Tray Sealing Machine: High-speed semi-automatic sealing for bulk production.

Shuttle Vacuum Tray Sealing Machine: Precision chamber vacuum for hygienic packaging.

Linpack Packaging Machines, established in 2000 as the international division of Zhejiang Mingrui Intelligent Equipment Technology Co., Ltd., is a national high-tech enterprise specializing in automated packaging solutions for food and non-food industries. With over 25 years of expertise, Linpack focuses on tray sealing machine manufacturing, delivering one-stop systems including modified atmosphere packaging (MAP) tray sealers, vacuum pouch packers, and premade bag fillers. Operating from a 100,000-square-meter facility in Rui'an City, China, the company serves global clients in fresh produce, ready-to-eat meals, and pharmaceuticals, emphasizing precision sealing to extend shelf life and ensure product freshness.

Professional Qualifications and Achievements

Linpack holds ISO9001 Quality Management System certification, Environmental Management System approval, Occupational Health and Safety standards, CE marking, and GMP compliance, ensuring reliable tray sealing machine production. Key achievements include over 2,600 annual machine sales, 100% user satisfaction rates, 58+ technology patents, and partnerships with more than 2,600 clients worldwide. As a top-ranked manufacturer in output and market share, Linpack's innovations in gas flushing tray sealers have earned recognition at international events like IFFA.

Experience and Cases

With mature pre-sales, in-sales, and after-sales networks, Linpack has deployed tray sealing solutions for thousands of users, optimizing efficiency in high-volume food processing. Notable cases involve MAP tray sealing for fresh meats like pork and salmon, achieving 99.9% gas replacement rates and up to 3,600 trays per hour. In ready-to-eat applications, such as braised duck and salads, their systems reduced film waste by 15-20% while maintaining airtight seals, as demonstrated in operational videos and client implementations across chemical and pharmaceutical sectors.

Team and Innovation

Linpack's team of seasoned mechanical engineers and technicians provides remote and on-site support, guided by core values of innovation, precision, service, and faith. Their advanced R&D center drives breakthroughs like intelligent control systems for quick mold swaps in tray sealing machines (5-10 minutes) and low-oxygen vacuum tech (0.1% residual rate), fostering customized solutions that boost productivity and sustainability.

Key Products and Services

Tray Sealing Machines: MAP gas flushing and vacuum sealing for fresh food preservation.

Vacuum Packaging Machines: Air evacuation and pouch sealing for extended shelf life in meats and produce.

Premade Pouch Packing Machines: Automatic filling and rotary sealing for granules, liquids, and sauces.

Roberts Technology Group, Inc. (RTG), established in 1995, stands as a premier tray sealing machine manufacturer and distributor in North America, exclusively representing ILPRA and SOLLAS brands for advanced packaging solutions. Specializing in tray sealing machines, thermoformers, and fill-sealers, RTG delivers robust, efficient equipment tailored for industries like food processing, cosmetics, pharmaceuticals, and personal care. Their machinery ensures airtight seals to preserve freshness, extend shelf life, and minimize waste, supporting high-throughput operations from small delis to large-scale manufacturers. With a commitment to turnkey installations, onsite training, and responsive maintenance, RTG optimizes packaging lines for seamless integration with conveyors, checkweighers, and metal detectors.

Professional Qualifications and Achievements

In terms of professional qualifications and achievements, RTG's tray sealing machines are produced in ISO-certified facilities, featuring IP65 washdown ratings, 304/316 stainless steel construction, and CE certification for reliability and hygiene. As a key player among tray sealing machine manufacturers, they champion the patented PROGAS method in modified atmosphere packaging (MAP), which boosts sealing speeds by up to 30%, reduces gas consumption, and enhances product quality for perishable goods like meat, poultry, and seafood. RTG's innovations have earned recognition for sustainability, notably through partnerships that cut plastic usage by 90% while maintaining MAP efficacy, positioning them as trusted experts in vacuum skin packaging (VSP) and high-pressure pasteurization (HPP)-compatible seals.

Experience and Cases

Drawing on nearly three decades of experience, RTG has powered diverse case studies in tray sealing applications. For instance, their collaboration with Lei™ Tray integrates compostable, recyclable materials with MAP-enabled tray sealing machines to combat food waste, extending shelf life for ready meals and produce by displacing oxygen via nitrogen injection and vacuum processes. This approach has helped family-owned poultry processors and major seafood operations scale production while retaining flavor, color, and nutritional value, demonstrating RTG's prowess in customizing tray sealing solutions for real-world efficiency.

Team and Innovation

RTG's team of seasoned engineers and service specialists excels in consultative expertise, from heat-sealing parameter optimization to programmable controls for multi-format adaptability. Driving innovation, they pioneer automated tray sealing machine designs that minimize labor, downtime, and costs, incorporating user-friendly interfaces for quick changeovers and end-to-end workflow automation—solidifying their role as forward-thinking tray sealing machine manufacturers.

Best Products and Services

Tray Sealing Machines: Modified atmosphere packaging and vacuum skin packaging services for extended shelf life in food and pharma applications.

Thermoforming Machines: Heat sealing and gas flush integration for high-volume, customizable tray production.

Fill-Seal Equipment: Automatic filling and sealing solutions for ready meals, dairy, and produce to ensure precision and hygiene.

Choosing the right tray sealing machine manufacturer in the USA requires balancing performance, regulatory compliance, automation capability, and long-term operational costs. While the top manufacturers each offer unique strengths—from advanced MAP technology to high-capacity industrial sealing systems—the best choice ultimately depends on your specific production goals and packaging requirements. As the industry continues to shift toward intelligent automation and eco-friendly materials in 2025, investing in equipment that ensures consistency, reliability, and adaptability has never been more important.

If you're seeking a trusted partner with strong expertise not only in tray sealing solutions but also in Cup Filling and Sealing Machine technology, Yijianuo Machinery is ready to support your production needs. With a focus on precision engineering, customizable configurations, and long-term service stability, Yijianuo Machinery helps businesses build efficient, scalable, and high-quality packaging lines.

Contact Yijianuo Machinery today to discuss your project and discover how the right sealing solution can elevate your packaging performance.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.