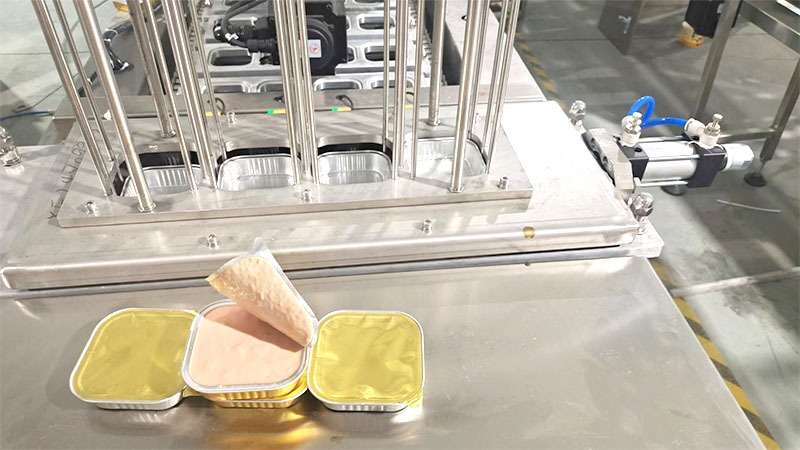

A tray filling and sealing machine is specialized packaging equipment designed to fill products into trays and hermetically seal them with film or lids. These machines are widely used across industries such as food processing, pharmaceuticals, cosmetics, and consumer goods, ensuring that products are securely packaged, hygienic, and visually appealing.

The machine operates by automatically loading trays, filling them with a measured amount of product, and sealing the top layer using heat and pressure. Some advanced models integrate vacuum or Modified Atmosphere Packaging (MAP) systems to extend product shelf life by reducing oxygen inside the package.

In 2025, demand for automated tray sealing machines continues to grow, driven by the global push for sustainable, tamper-evident packaging and the need to minimize human handling in production environments. Businesses adopting tray filling and sealing systems benefit from consistent product quality, improved hygiene standards, and higher packaging efficiency, making them a key component in modern manufacturing lines.

Tray filling and sealing machines come in various configurations, each designed to match specific production volumes, packaging materials, and automation needs. Understanding the key types helps businesses select the right system for efficiency, cost control, and long-term reliability.

Manual tray sealers are ideal for small-scale production, pilot runs, or laboratory packaging. Operators manually load trays and activate the sealing process, making these machines affordable and easy to use. While they offer lower throughput, they are perfect for small food producers, test kitchens, or research facilities that prioritize flexibility over speed.

Semi-automatic systems combine manual loading with automated sealing. These machines can handle moderate production volumes, offering a balance between labor efficiency and investment cost. They are often used by medium-sized food manufacturers and ready-meal producers, especially those packaging fresh produce, meat, or prepared dishes.

Fully automatic tray sealers represent the highest level of automation. They feature automated tray loading, product filling, film sealing, and cutting, requiring minimal human intervention. These systems are designed for continuous, high-speed operations and are commonly found in large food processing plants, pharmaceutical facilities, and industrial packaging lines.

For perishable products, MAP (Modified Atmosphere Packaging) and vacuum tray sealing machines are widely used. They replace oxygen inside the tray with inert gases like nitrogen or carbon dioxide, significantly extending shelf life while maintaining product freshness. These technologies are essential in meat, seafood, cheese, and ready-to-eat meal packaging.

Choosing between manual, semi-automatic, and fully automatic systems depends on production scale, packaging type, and hygiene requirements. In 2025, many manufacturers are upgrading to automated tray filling and sealing machines to stay competitive, reduce waste, and ensure consistent packaging quality.

Selecting the right tray filling and sealing machine requires a detailed understanding of the machine’s technical specifications and how they align with your production goals. Whether you’re packaging food, pharmaceuticals, or consumer goods, evaluating these key features ensures long-term performance and cost efficiency.

A top priority when choosing a machine is its ability to handle various tray sizes and formats. Some advanced systems come with adjustable molds and interchangeable tooling, allowing quick changeovers between different tray shapes and depths — a critical feature for manufacturers running multiple product lines.

The machine’s output speed, often measured in trays per minute, directly impacts production efficiency. For high-volume operations, fully automatic tray sealers can process hundreds of trays per hour. Small or medium producers might prefer semi-automatic options that balance throughput with cost-effectiveness.

Modern tray sealers support a range of materials, including PP, PET, PE, CPET, and aluminum. The sealing method — typically heat sealing or pressure sealing — must be compatible with both tray and film materials to achieve a consistent, airtight seal. Machines designed for MAP (Modified Atmosphere Packaging) or vacuum sealing offer superior product preservation, especially for perishable goods.

Buyers should consider how easily the machine integrates with existing production lines, such as filling, labeling, or carton packaging systems. Features like automatic tray denesting, film cutting, and coding modules enhance productivity and reduce manual labor.

For food and pharmaceutical industries, hygiene is non-negotiable. Machines made from stainless steel with smooth, washable surfaces help maintain strict sanitation standards. Easy access for cleaning, tool-free maintenance, and self-diagnostic systems are also valuable for minimizing downtime.

As sustainability becomes a key focus in 2025, many manufacturers are adopting energy-efficient tray sealers that consume less power and support biodegradable or recyclable packaging materials. These machines not only lower operational costs but also align with global environmental regulations.

In summary, evaluating these technical factors before purchasing a tray filling and sealing machine ensures you invest in equipment that delivers reliability, speed, and long-term return on investment.

Modern tray filling and sealing machines play a crucial role in achieving efficient, hygienic, and sustainable packaging. From improving product shelf life to reducing operational costs, their advantages go far beyond traditional packaging methods. Below are the main benefits that make these machines indispensable across industries in 2025.

One of the most significant advantages is the ability to deliver airtight, tamper-evident seals that protect products from contamination and moisture. When paired with MAP (Modified Atmosphere Packaging) or vacuum sealing, these systems extend the freshness and shelf life of perishable items such as ready-to-eat meals, seafood, and dairy products.

Automated tray filling and sealing machines drastically reduce manual handling and packaging time. By streamlining the filling, sealing, and labeling processes, companies can increase output while minimizing labor costs and human error. Over time, this leads to a measurable return on investment (ROI) through improved production flow and reduced waste.

For food and pharmaceutical manufacturers, hygiene is a key priority. These machines are designed with stainless steel construction, sealed electronics, and easy-to-clean components to comply with strict international safety standards such as HACCP and ISO 22000. Automated systems also minimize direct human contact, reducing the risk of contamination.

A tray sealing machine can handle a variety of products — from liquid and semi-liquid foods to powders, snacks, and non-food items like cosmetics or medical kits. This flexibility allows businesses to diversify their product lines without investing in separate packaging systems.

As the global packaging industry moves toward sustainability, new tray sealing technologies support recyclable and biodegradable materials. Advanced heat-sealing systems ensure strong seals even with eco-friendly films and trays, helping brands reduce their environmental footprint while maintaining packaging integrity.

Tray-sealed packages offer a clean, premium appearance that enhances shelf presentation and brand image. Clear-lid sealing options allow consumers to see the product, improving trust and purchase intent — a key advantage in competitive retail environments.

In short, adopting a tray filling and sealing machine helps manufacturers achieve higher productivity, safer operations, and stronger brand competitiveness — all essential for success in 2025’s fast-evolving packaging market.

Investing in a tray filling and sealing machine is a strategic decision that can significantly influence production efficiency, packaging quality, and long-term profitability. With the wide variety of models and configurations available in 2025, businesses must evaluate their specific needs carefully. The following factors can guide you in choosing the right equipment for your operation.

Start by assessing your daily output, product type, and tray format. Small producers may benefit from a semi-automatic tray sealer, while large-scale manufacturers handling thousands of trays per hour should invest in a fully automatic tray sealing system. Understanding your target production volume helps prevent under- or over-investment.

Different products require different sealing technologies. For example, fresh meat, seafood, and ready meals perform best with MAP or vacuum tray sealing machines, while bakery or dry goods may only need standard heat-sealing systems. Ensure your chosen model supports the tray and film materials you use — such as PET, PP, or aluminum — to guarantee compatibility and seal integrity.

Modern production lines often require seamless connectivity between equipment. Look for machines that can integrate with weighing, labeling, or carton packaging systems. Features such as automatic tray denesting, film positioning, and coding can further reduce human intervention and maximize operational efficiency.

A high-quality tray sealing machine is only as good as the support behind it. Choose reputable manufacturers that provide installation, training, spare parts availability, and technical service. This ensures minimal downtime and a longer lifespan for your investment.

If your business operates in food or pharmaceutical packaging, make sure the equipment meets hygiene standards such as HACCP, CE, or FDA certification. Machines with stainless steel frames, sealed wiring, and tool-free cleaning access will help you maintain compliance and ensure a sanitary production environment.

Price should never be the sole deciding factor. A cheaper machine may lead to higher maintenance costs, inconsistent sealing quality, or limited upgrade options. Evaluate total cost of ownership (TCO) — including power usage, maintenance frequency, and future scalability — to ensure sustainable profitability.

Before finalizing your decision, it’s wise to request a machine demo or send sample trays to the manufacturer for testing. This allows you to verify sealing performance, throughput, and ease of use under your actual production conditions.

By carefully considering these factors, you can confidently select a tray filling and sealing machine that matches your current operations while supporting your business growth for years to come.

Yijianuo Machinery, officially known as Wuhan City Yijianuo Machinery Co., Ltd., stands as a premier tray filling and sealing machine manufacturer dedicated to delivering advanced automatic packaging solutions for the food, beverage, pharmaceutical, and daily chemical sectors. Boasting over 13 years of production experience since its founding in 2012, the company has honed its expertise in designing and producing reliable tray filling and sealing machines that prioritize precision, hygiene, and efficiency in packaging processes. In terms of development status, Yijianuo has rapidly expanded into a full-service innovator in tray filling and sealing machine technology, earning ISO9001 certification and building a global network with overseas warehouses for seamless support; it now employs over 160 professionals focused on R&D, customization, and sustainable tray filling and sealing machine advancements to meet diverse industry demands. The company's factory status reflects its commitment to scalable operations, with a state-of-the-art production base spanning more than 10,000 square meters in Yangluo Development Zone, Wuhan, Hubei Province, where integrated mechanical processing enables high-output manufacturing of tray filling and sealing machines alongside comprehensive quality control and assembly lines.

Best products:

Thermoforming Tray Filling and Sealing Machine: customized production and global warranty services

Automatic High Speed Tray Filling and Sealing Machine: 24/7 technical support and after-sales maintenance services

Aluminum Foil Tray Filling and Sealing Machine: installation and operator training services

Pet Food Tray Filling and Sealing Machine: spare parts supply and equipment upgrade services

Foil Tray Filling and Sealing Machine: system integration and compliance consulting services

ProSeal is a premier tray filling and sealing machine manufacturer renowned for delivering advanced tray sealing solutions tailored to the food packaging sector, with a strong emphasis on automatic tray sealing machines, semi-automatic tray filling and sealing systems, and custom tray sealing technologies that ensure hygienic, efficient, and sustainable packaging processes. Boasting over 25 years of production experience since its founding in 1998 in a modest unit in Bollington, UK, by Steve Malone and Robbie Hargreaves, the company has established itself as a global authority in tray filling and sealing machine innovation, designing and producing high-quality tray sealing equipment, conveyor integrations, and precision sealing tools that support diverse food applications from ready meals to fresh produce. In terms of development status, ProSeal has undergone remarkable expansion, achieving nearly 600 employees worldwide by 2023, installing its 8000th tray sealing machine in December 2024, and earning the prestigious Made in Britain designation in 2024 while being acquired by JBT Corporation in 2019 for £220 million, solidifying its position as the world leader in tray sealing technology with a focus on future-proof designs adaptable to evolving tray filling and sealing machine demands. The company's factories are centered at its expansive manufacturing headquarters in Adlington, Cheshire, UK—a state-of-the-art 250,000 square foot facility that has grown from a single building to multiple interconnected sites, enabling high-volume production of tray filling and sealing machines with 24/7 support capabilities and global distribution networks.

Best products:

Manual Tray Filling and Sealing Machine: hand-operated sealing for small-scale food trays with installation and training services

Semi-Automatic Tray Sealing Machine: versatile sealing for medium production food packaging with customization and tool changeover services

Automatic Tray Filling and Sealing Machine: high-throughput inline sealing for ready meals and fresh foods with 24/7 maintenance and conveyor integration services

High-Speed Twin Tray Sealing Machine: dual-lane filling and sealing for high-volume food lines with validation and upgrade services

Rocket Machine Works is a premier tray filling and sealing machine manufacturer dedicated to delivering custom rotary and inline tray filling and sealing solutions for the food packaging sector, including prepared meals, deli products, and institutional packaging. With over 30 years of production experience in engineering and assembling tray filling and sealing machines, the company draws on deep packaging knowledge to create robust, stainless steel systems that ensure precise filling, secure sealing, and compliance with FDA, NSF, and USDA standards. In terms of development status, Rocket Machine Works has advanced from its California roots into a dynamic provider of expandable tray filling and sealing machine lines, incorporating features like quick-change carriers, advanced temperature controls, and integrated auxiliary equipment such as volumetric fillers and denesters to minimize downtime, reduce labor costs, and support high-output tray filling and sealing operations; it actively engages in industry events like Pack Expo and maintains strong client relationships through reliable, on-time project delivery. The company's factories are situated in California's Central Valley—the heart of U.S. food production—where all tray filling and sealing machines are 100% custom designed, engineered, and manufactured using washdown components for longevity and ease of maintenance, with nationwide shipping and installation support.

Best products:

Rotary Tray Filling and Sealing Machines: system integration and technical support services

Inline Tray Filling and Sealing Machines: customization and after-sales maintenance services

Die-Cut Tray Sealing Machines: process optimization and training services

Stand-Alone Tray Filling Machines: equipment upgrades and spare parts supply services

Tray Denesting and Filling Systems: validation and compliance consulting services

JBT Corporation is a premier global provider of tray filling and sealing machine technologies, delivering innovative processing and packaging solutions for high-value segments of the food and beverage industry, with a strong emphasis on efficient tray filling and sealing machines that ensure product freshness, safety, and extended shelf life. Boasting over 140 years of production experience since its origins in 1884 with the founding of the Bean Spray Pump Company in California—initially focused on fruit spraying equipment that evolved into advanced food handling systems—JBT has built a legacy of pioneering tray filling and sealing machine developments, including early contributions to pasteurization, filling, and closure technologies that addressed key challenges in fruit processing and beyond. In terms of development status, JBT was formally incorporated in 2008 following the divestiture of non-energy businesses from FMC Technologies, marking a pivotal shift toward specialized food and air transportation solutions; since then, it has aggressively expanded through more than 20 strategic acquisitions, such as Proseal UK Limited in 2019 to bolster tray sealing expertise, Alco food-machines in 2022 for enhanced filling capabilities, and others like Stork Food & Dairy Systems in 2015, resulting in a robust portfolio of integrated tray filling and sealing machine systems that support sustainable practices like reduced plastic use and Modified Atmosphere Packaging (MAP). Today, with approximately 6,600 employees worldwide, JBT continues to innovate in tray filling and sealing machine efficiency, achieving milestones like installing its 8,000th tray sealing machine in early 2025, while maintaining a commitment to environmental, social, and governance (ESG) goals through energy-efficient designs and global R&D investments. The company's factories operate across a network of over 25 countries, with key manufacturing sites including the primary FoodTech facility in Middletown, Ohio, USA, for assembly and testing of tray filling and sealing machines; European production hubs in the UK (via Proseal) and Germany (via Schröder), focused on high-volume tray sealing output; and additional plants in the Netherlands and India for localized tray filling and sealing machine customization and support, all equipped with state-of-the-art automation, 24/7 service capabilities, and Research & Technology Centers for validation and prototyping to ensure seamless scalability and minimal downtime.

Best products:

Automatic Tray Filling and Sealing Machine: precise volumetric filling and vacuum gas sealing for ready meals

Semi-Automatic Tray Filling and Sealing Machine: rotary table filling and MAP sealing for fresh produce

High-Speed Inline Tray Filling and Sealing Machine: conveyor-integrated filling and atmospheric sealing up to 240 packs per minute

Granular Tray Filling and Sealing System: particulate filling and foil closure for snacks and pet food

Versatile Tray Filling and Sealing Solution: level filling and tamper-evident sealing for dairy and desserts

Reepack is a premier tray filling and sealing machine manufacturer renowned for delivering advanced packaging solutions tailored to the food, healthcare, and industrial sectors, with a strong emphasis on innovative tray filling and sealing machine technologies for preserving fresh and processed products. Established in 1997 in Seriate, Italy, the company brings over 28 years of production experience in designing and building reliable tray filling and sealing machines, evolving from a specialized Italian firm into a global leader through continuous investment in R&D and state-of-the-art servo-driven systems that ensure hygienic, efficient tray filling and sealing operations. In terms of development status, Reepack has experienced significant growth, including its acquisition by ProMach in 2022, which has expanded its international footprint with exports to worldwide markets and a dedicated branch in Germany to better serve European customers; this strategic move has bolstered its commitment to Industry 4.0 standards via the ReeNEXT digital platform, enhancing connectivity and efficiency in tray filling and sealing machine deployments while maintaining certifications like ISO 9001 for quality and ISO 45001 for safety. The company's factories are centered at its headquarters in Seriate (Bergamo province), Italy, where it conducts all core manufacturing, assembly, and testing of tray filling and sealing machines in a single, high-tech facility focused on modular designs and rapid customization to meet diverse production needs.

Best products:

High-output automatic tray filling and sealing machine

Entry-level automatic tray filling and sealing machine

Semi-automatic tray filling and sealing machine

Thermoform fill seal tray machine

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.