A tray filling and sealing machine is specialized packaging equipment designed to fill products into trays and hermetically seal them with film or lids. These machines are widely used across industries such as food processing, pharmaceuticals, cosmetics, and consumer goods, ensuring that products are securely packaged, hygienic, and visually appealing.

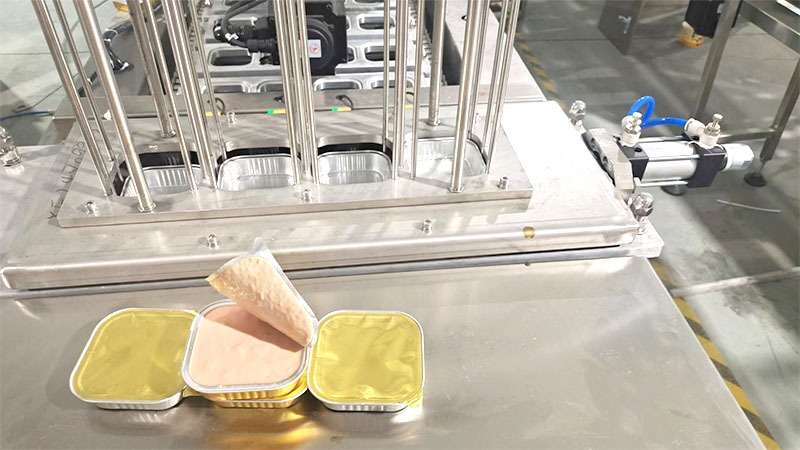

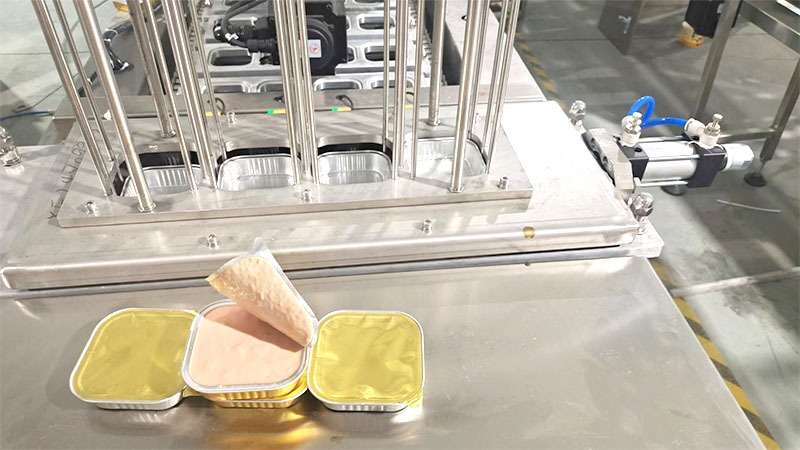

The machine operates by automatically loading trays, filling them with a measured amount of product, and sealing the top layer using heat and pressure. Some advanced models integrate vacuum or Modified Atmosphere Packaging (MAP) systems to extend product shelf life by reducing oxygen inside the package.

In 2025, demand for automated tray sealing machines continues to grow, driven by the global push for sustainable, tamper-evident packaging and the need to minimize human handling in production environments. Businesses adopting tray filling and sealing systems benefit from consistent product quality, improved hygiene standards, and higher packaging efficiency, making them a key component in modern manufacturing lines.

Tray filling and sealing machines come in various configurations, each designed to match specific production volumes, packaging materials, and automation needs. Understanding the key types helps businesses select the right system for efficiency, cost control, and long-term reliability.

Manual tray sealers are ideal for small-scale production, pilot runs, or laboratory packaging. Operators manually load trays and activate the sealing process, making these machines affordable and easy to use. While they offer lower throughput, they are perfect for small food producers, test kitchens, or research facilities that prioritize flexibility over speed.

Semi-automatic systems combine manual loading with automated sealing. These machines can handle moderate production volumes, offering a balance between labor efficiency and investment cost. They are often used by medium-sized food manufacturers and ready-meal producers, especially those packaging fresh produce, meat, or prepared dishes.

Fully automatic tray sealers represent the highest level of automation. They feature automated tray loading, product filling, film sealing, and cutting, requiring minimal human intervention. These systems are designed for continuous, high-speed operations and are commonly found in large food processing plants, pharmaceutical facilities, and industrial packaging lines.

For perishable products, MAP (Modified Atmosphere Packaging) and vacuum tray sealing machines are widely used. They replace oxygen inside the tray with inert gases like nitrogen or carbon dioxide, significantly extending shelf life while maintaining product freshness. These technologies are essential in meat, seafood, cheese, and ready-to-eat meal packaging.

Choosing between manual, semi-automatic, and fully automatic systems depends on production scale, packaging type, and hygiene requirements. In 2025, many manufacturers are upgrading to automated tray filling and sealing machines to stay competitive, reduce waste, and ensure consistent packaging quality.

Selecting the right tray filling and sealing machine requires a detailed understanding of the machine’s technical specifications and how they align with your production goals. Whether you’re packaging food, pharmaceuticals, or consumer goods, evaluating these key features ensures long-term performance and cost efficiency.

A top priority when choosing a machine is its ability to handle various tray sizes and formats. Some advanced systems come with adjustable molds and interchangeable tooling, allowing quick changeovers between different tray shapes and depths — a critical feature for manufacturers running multiple product lines.

The machine’s output speed, often measured in trays per minute, directly impacts production efficiency. For high-volume operations, fully automatic tray sealers can process hundreds of trays per hour. Small or medium producers might prefer semi-automatic options that balance throughput with cost-effectiveness.

Modern tray sealers support a range of materials, including PP, PET, PE, CPET, and aluminum. The sealing method — typically heat sealing or pressure sealing — must be compatible with both tray and film materials to achieve a consistent, airtight seal. Machines designed for MAP (Modified Atmosphere Packaging) or vacuum sealing offer superior product preservation, especially for perishable goods.

Buyers should consider how easily the machine integrates with existing production lines, such as filling, labeling, or carton packaging systems. Features like automatic tray denesting, film cutting, and coding modules enhance productivity and reduce manual labor.

For food and pharmaceutical industries, hygiene is non-negotiable. Machines made from stainless steel with smooth, washable surfaces help maintain strict sanitation standards. Easy access for cleaning, tool-free maintenance, and self-diagnostic systems are also valuable for minimizing downtime.

As sustainability becomes a key focus in 2025, many manufacturers are adopting energy-efficient tray sealers that consume less power and support biodegradable or recyclable packaging materials. These machines not only lower operational costs but also align with global environmental regulations.

In summary, evaluating these technical factors before purchasing a tray filling and sealing machine ensures you invest in equipment that delivers reliability, speed, and long-term return on investment.

Modern tray filling and sealing machines play a crucial role in achieving efficient, hygienic, and sustainable packaging. From improving product shelf life to reducing operational costs, their advantages go far beyond traditional packaging methods. Below are the main benefits that make these machines indispensable across industries in 2025.

One of the most significant advantages is the ability to deliver airtight, tamper-evident seals that protect products from contamination and moisture. When paired with MAP (Modified Atmosphere Packaging) or vacuum sealing, these systems extend the freshness and shelf life of perishable items such as ready-to-eat meals, seafood, and dairy products.

Automated tray filling and sealing machines drastically reduce manual handling and packaging time. By streamlining the filling, sealing, and labeling processes, companies can increase output while minimizing labor costs and human error. Over time, this leads to a measurable return on investment (ROI) through improved production flow and reduced waste.

For food and pharmaceutical manufacturers, hygiene is a key priority. These machines are designed with stainless steel construction, sealed electronics, and easy-to-clean components to comply with strict international safety standards such as HACCP and ISO 22000. Automated systems also minimize direct human contact, reducing the risk of contamination.

A tray sealing machine can handle a variety of products — from liquid and semi-liquid foods to powders, snacks, and non-food items like cosmetics or medical kits. This flexibility allows businesses to diversify their product lines without investing in separate packaging systems.

As the global packaging industry moves toward sustainability, new tray sealing technologies support recyclable and biodegradable materials. Advanced heat-sealing systems ensure strong seals even with eco-friendly films and trays, helping brands reduce their environmental footprint while maintaining packaging integrity.

Tray-sealed packages offer a clean, premium appearance that enhances shelf presentation and brand image. Clear-lid sealing options allow consumers to see the product, improving trust and purchase intent — a key advantage in competitive retail environments.

In short, adopting a tray filling and sealing machine helps manufacturers achieve higher productivity, safer operations, and stronger brand competitiveness — all essential for success in 2025’s fast-evolving packaging market.

Investing in a tray filling and sealing machine is a strategic decision that can significantly influence production efficiency, packaging quality, and long-term profitability. With the wide variety of models and configurations available in 2025, businesses must evaluate their specific needs carefully. The following factors can guide you in choosing the right equipment for your operation.

Start by assessing your daily output, product type, and tray format. Small producers may benefit from a semi-automatic tray sealer, while large-scale manufacturers handling thousands of trays per hour should invest in a fully automatic tray sealing system. Understanding your target production volume helps prevent under- or over-investment.

Different products require different sealing technologies. For example, fresh meat, seafood, and ready meals perform best with MAP or vacuum tray sealing machines, while bakery or dry goods may only need standard heat-sealing systems. Ensure your chosen model supports the tray and film materials you use — such as PET, PP, or aluminum — to guarantee compatibility and seal integrity.

Modern production lines often require seamless connectivity between equipment. Look for machines that can integrate with weighing, labeling, or carton packaging systems. Features such as automatic tray denesting, film positioning, and coding can further reduce human intervention and maximize operational efficiency.

A high-quality tray sealing machine is only as good as the support behind it. Choose reputable manufacturers that provide installation, training, spare parts availability, and technical service. This ensures minimal downtime and a longer lifespan for your investment.

If your business operates in food or pharmaceutical packaging, make sure the equipment meets hygiene standards such as HACCP, CE, or FDA certification. Machines with stainless steel frames, sealed wiring, and tool-free cleaning access will help you maintain compliance and ensure a sanitary production environment.

Price should never be the sole deciding factor. A cheaper machine may lead to higher maintenance costs, inconsistent sealing quality, or limited upgrade options. Evaluate total cost of ownership (TCO) — including power usage, maintenance frequency, and future scalability — to ensure sustainable profitability.

Before finalizing your decision, it’s wise to request a machine demo or send sample trays to the manufacturer for testing. This allows you to verify sealing performance, throughput, and ease of use under your actual production conditions.

By carefully considering these factors, you can confidently select a tray filling and sealing machine that matches your current operations while supporting your business growth for years to come.

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.